This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

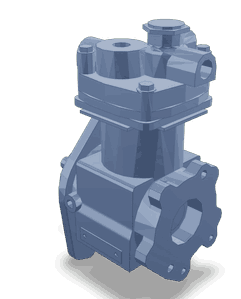

The Cummins 3906251 Air Compressor is a component designed to enhance the operational efficiency of commercial trucks. It is integral to the truck’s air brake system, ensuring that the necessary air pressure is generated and maintained for safe and effective braking. This compressor is part of Cummins’ lineup of reliable and durable components that contribute to the overall performance and safety of heavy-duty vehicles 1.

Basic Concepts of Air Compressors

An air compressor is a device that converts power into potential energy stored in pressurized air. It operates by drawing in air, compressing it, and then storing it in a tank until needed. In commercial trucks, air compressors are primarily used to power the air brake system, which requires a consistent supply of compressed air to function correctly. Additionally, compressed air is utilized in other systems such as suspension, air horns, and pneumatic tools 2.

Purpose of the 3906251 Air Compressor

This part plays a significant role in the operation of a truck by generating and maintaining the air pressure required for the air brake system. It ensures that the brakes can be applied and released efficiently, contributing to the safety and control of the vehicle. Furthermore, it supports other pneumatic systems on the truck, enhancing overall functionality and performance.

Key Features

This Cummins part is characterized by several key features that enhance its performance and reliability. Its design incorporates high-quality materials that are resistant to wear and corrosion, ensuring durability in demanding environments. The compressor is engineered with precision to deliver consistent air pressure, and it includes advanced technological aspects such as efficient cooling systems and noise reduction features to improve operation and longevity.

Benefits

This part offers several benefits that contribute to improved efficiency, reliability, and performance in truck operations. Its robust construction and advanced features result in a compressor that requires less maintenance and provides consistent performance under various conditions. Additionally, the compressor’s efficient operation helps reduce fuel consumption, contributing to cost savings and environmental benefits.

Installation Process

Installing this part involves several steps to ensure proper integration into the truck’s system. Prerequisites include ensuring the truck’s engine and electrical systems are compatible with the compressor. The installation process requires specific tools and should be performed by a qualified technician. Steps include mounting the compressor, connecting it to the air lines, and ensuring all electrical connections are secure. Detailed instructions should be followed to avoid complications.

Common Issues and Troubleshooting

Common issues with this part may include insufficient air pressure, unusual noises, or leaks. Troubleshooting these problems involves checking the compressor’s connections, inspecting for leaks, and ensuring the compressor is receiving adequate power. Regular maintenance and prompt attention to any signs of trouble can help prevent more serious issues and ensure the compressor operates efficiently.

Maintenance Tips

To ensure the longevity and optimal performance of this part, regular maintenance is recommended. This includes checking for leaks, ensuring all connections are secure, and monitoring the compressor’s performance. It is also important to keep the compressor clean and free from debris that could affect its operation. Following the manufacturer’s maintenance schedule will help maintain the compressor’s efficiency and reliability.

Safety Considerations

When working with this part, it is important to follow safety guidelines to prevent accidents and ensure safe operation. This includes wearing appropriate personal protective equipment, ensuring the compressor is turned off and disconnected from power before performing maintenance, and being aware of the high-pressure air that the compressor generates. Adhering to these safety considerations will help protect both the technician and the equipment.

Cummins Corporation

Cummins Corporation is a renowned manufacturer with a long-standing reputation in the industry for producing high-quality automotive components. Founded in 1919, Cummins has a history of innovation and commitment to excellence. The company is dedicated to providing reliable and efficient solutions for the automotive and heavy-duty truck sectors, with a focus on sustainability and performance 3.

Cummins Air Compressor Part 3906251 Compatibility

This part is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is engineered to work with the following Cummins engines:

- 4B3.9

- 6B5.9

- 6C8.3

These engines, while differing in their specific configurations and applications, share common design elements that make the 3906251 air compressor a versatile and compatible choice. The air compressor is meticulously crafted to meet the stringent demands of these engines, providing essential air supply for various functions, including starting, lubrication, and cooling systems.

By integrating the 3906251 air compressor into these engines, users can expect enhanced efficiency and durability, contributing to the overall longevity and performance of the engine. This compatibility ensures that the air compressor can effectively support the operational needs of these engines, regardless of their specific application or environment.

Role of Part 3906251 Air Compressor in Engine Systems

This part is an essential component in various engine systems, facilitating the efficient operation of several interconnected parts.

When integrated into an engine system, the air compressor works in tandem with the turbocharger to enhance the engine’s performance. The compressor section of the turbocharger draws in ambient air and compresses it before it enters the engine’s intake manifold. This pressurized air increases the oxygen content within the combustion chamber, allowing for more fuel to be burned and thus generating more power.

In conjunction with the intercooler, the air compressor ensures that the compressed air is cooled before it enters the engine. This cooling process increases the air density, further improving combustion efficiency and power output.

The air compressor also plays a significant role in the operation of the engine’s emissions control system. By providing a consistent supply of pressurized air, it helps maintain optimal air-fuel ratios, which are essential for the efficient functioning of catalytic converters and other emissions control devices.

Additionally, the compressor contributes to the engine’s overall durability and reliability. By ensuring a steady supply of pressurized air, it reduces the stress on other engine components, such as the pistons and cylinders, leading to a longer engine lifespan.

Conclusion

In summary, the 3906251 air compressor is a vital component that enhances engine performance, efficiency, and reliability through its interaction with the turbocharger, intercooler, and emissions control systems. Regular maintenance, proper installation, and adherence to safety guidelines are essential to ensure the longevity and optimal performance of this part.

-

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.