This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

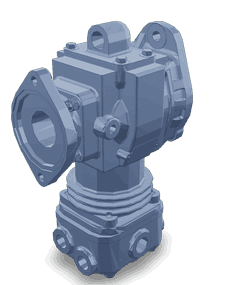

The Cummins 3974548 Air Compressor is a component designed for use in commercial trucks. It serves to generate and maintain the compressed air necessary for various truck systems. Its role is significant in ensuring the efficient operation of pneumatic systems, which are integral to the functionality of commercial vehicles 1.

Basic Concepts of Air Compressors

An air compressor is a device that converts power into potential energy stored in pressurized air. By compressing air, the compressor increases its pressure, which can then be used to perform work. In various industries, air compressors are utilized for powering tools, operating machinery, and supporting pneumatic systems. In the context of commercial trucks, air compressors are vital for the operation of brakes, suspensions, and other systems that rely on compressed air 2.

Role of the 3974548 Air Compressor in Truck Operation

This Cummins part contributes to the operation of a truck by supplying the compressed air required for its pneumatic systems. This includes the air brake system, which relies on pressurized air to function effectively. Additionally, the compressor supports air suspension systems, which use compressed air to adjust the ride height and improve handling. The consistent supply of compressed air ensures that these systems operate reliably under various conditions 3.

Key Features

This part is characterized by its robust design and high-quality construction. It incorporates technological advancements that enhance its performance and durability. These features include precision engineering, the use of durable materials, and innovative design elements that improve efficiency and reliability.

Benefits of Using the 3974548 Air Compressor

Installing this part in commercial trucks offers several advantages. These include improved efficiency in air production, enhanced reliability of the truck’s pneumatic systems, and performance enhancements that contribute to the overall effectiveness of the vehicle. The compressor’s design ensures that it can meet the demands of commercial truck operations, providing consistent and reliable performance 4.

Installation and Integration

Proper installation and integration of this part into a truck’s existing system require attention to detail and adherence to manufacturer guidelines. This process involves ensuring that the compressor is correctly mounted, connected to the appropriate systems, and that all electrical and pneumatic connections are secure. Consideration should be given to the truck’s specific requirements and any modifications that may be necessary to accommodate the compressor.

Maintenance and Care

To ensure the longevity and optimal performance of this part, routine maintenance and care are recommended. This includes regular inspection of the compressor and its components, cleaning or replacing filters as needed, and checking for any signs of wear or damage. Adhering to a maintenance schedule helps prevent issues and ensures that the compressor continues to operate efficiently.

Troubleshooting Common Issues

Common issues that may arise with this part can often be addressed through systematic troubleshooting. This involves identifying the symptoms of the problem, such as a decrease in air pressure or unusual noises, and then diagnosing the cause. Potential solutions may include adjusting settings, replacing worn components, or seeking professional repair services if necessary.

Performance Enhancements

This part can contribute to overall truck performance in several ways. By ensuring a consistent supply of compressed air, it supports the efficient operation of the truck’s pneumatic systems. This can lead to improvements in fuel efficiency and operational reliability, as the truck’s systems are able to function as intended without interruption.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted provider of commercial vehicle components. The company’s focus on technological advancement and customer satisfaction has positioned it as a leader in the industry, with a wide range of products designed to meet the needs of commercial truck operators.

Cummins Air Compressor Part 3974548 Compatibility

This part is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This part is specifically engineered to integrate with the following engine models:

- 4B3.9

- 6B5.9

- B5.9 GAS PLUS CM556

These engines, while differing in their specific configurations and applications, share common design principles that allow the 3974548 air compressor to function effectively. The compatibility of this air compressor with these engines is a testament to Cummins’ commitment to providing high-quality, versatile components that meet the demands of various industrial and commercial applications.

Role of Part 3974548 Air Compressor in Engine Systems

This part is integral to the operation of various engine systems, enhancing performance and efficiency. In the context of an engine, the air compressor is responsible for pressurizing the intake air before it enters the combustion chamber. This pressurized air, when mixed with fuel, leads to a more efficient and powerful combustion process.

Integration with Engine Components

-

Intake System: The air compressor works in conjunction with the intake system to deliver a higher volume of air into the engine. This pressurized air is essential for optimal fuel combustion, especially in turbocharged or supercharged engines where the demand for air is significantly higher.

-

Fuel Injection System: With the increased air pressure provided by the compressor, the fuel injection system can deliver a precise amount of fuel to match the air-fuel ratio required for efficient combustion. This synergy ensures that the engine operates at peak performance without unnecessary fuel wastage.

-

Exhaust System: The enhanced combustion efficiency resulting from the pressurized air leads to a more complete burn of the fuel. This, in turn, reduces the amount of unburnt fuel and other pollutants in the exhaust, contributing to a cleaner and more efficient exhaust system.

-

Engine Control Unit (ECU): Modern engines are equipped with an ECU that monitors and adjusts various parameters in real-time. The air compressor’s role is vital here, as the ECU relies on consistent and reliable air pressure to make accurate adjustments to fuel delivery and ignition timing.

-

Turbocharger/Supercharger: In engines equipped with turbochargers or superchargers, the air compressor plays a supporting role. It ensures that the forced induction system receives a steady supply of pressurized air, which is then further compressed by the turbocharger or supercharger for even greater engine performance.

-

Intercooler: Often used in conjunction with turbochargers, the intercooler cools the compressed air before it enters the combustion chamber. The air compressor ensures that the intercooler receives a consistent flow of pressurized air, which is then cooled to increase its density and further improve engine efficiency.

Conclusion

In summary, the 3974548 air compressor is a key component that enhances the functionality of various engine systems, leading to improved performance, efficiency, and reduced emissions. Its integration with the intake, fuel injection, exhaust, and other engine components ensures that the engine operates at peak performance, contributing to the overall effectiveness of commercial trucks.

-

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ -

Bruce Maclaurin, High Speed Off-Road Vehicles (Wiley, 2018).

↩ -

Quansheng Zhan, Shengbo Eben, Li Kun Deng, Automotive Heating Ventilation and Air Conditioning (Jones Bartlett Learning, 2018).

↩ -

Hermann Hiereth, Peter Prenninger and Klaus W Drexl, Charging the Internal Combustion Engine (Springer, 2010).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.