3921836

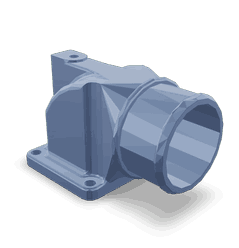

Air Intake Connection

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Air Intake Connection part 3921836 is a critical component in the heavy-duty truck industry, designed to facilitate the intake of air into the engine. This part is integral to the combustion process and overall engine operation, reflecting Cummins’ reputation for high-quality engine components 1.

Basic Concepts of Air Intake Connections

An air intake connection serves as a conduit between the air filter and the engine’s intake manifold. Its role is to channel clean, filtered air into the engine, where it mixes with fuel for combustion. The efficiency of this process is pivotal for the engine’s performance, including power output, fuel efficiency, and emissions levels 2.

Purpose of the 3921836 Air Intake Connection

The 3921836 Air Intake Connection is engineered to provide a secure and efficient pathway for air to enter the engine. It is designed to endure the demanding conditions of heavy-duty truck environments, ensuring a consistent and uncontaminated air supply. This contributes to the engine’s efficiency and performance 3.

Key Features

Constructed from high-quality materials, the 3921836 Air Intake Connection offers durability and resistance to environmental factors. Its design includes precise fittings and seals to ensure a tight connection, minimizing the risk of air leaks. This part is also compatible with a range of Cummins engines, offering versatility and ease of integration 4.

Benefits

Utilizing the 3921836 Air Intake Connection can lead to improved engine efficiency due to a consistent and clean air supply. This results in reduced wear on engine components and can potentially increase fuel economy, making it a valuable component for fleet operators 5.

Installation and Integration

Proper installation of the 3921836 Air Intake Connection is crucial for maintaining the integrity of the air intake system. It is important to follow the manufacturer’s guidelines, ensuring compatibility with the specific engine model and securing all connections to prevent obstructions 6.

Maintenance and Troubleshooting

Regular maintenance of the 3921836 Air Intake Connection is essential for its efficient operation. This includes inspecting for wear or damage, cleaning debris, and checking for leaks or blockages. Troubleshooting common issues such as leaks can often be resolved by tightening connections or replacing worn seals 7.

Performance Impact

The 3921836 Air Intake Connection can significantly impact the overall performance of the truck. By ensuring a consistent and clean air supply to the engine, it contributes to increased torque and horsepower outputs. Additionally, a well-functioning air intake system can help reduce emissions, as the combustion process is more efficient with an optimal air-fuel mixture 8.

Cummins Overview

Cummins Inc., a global power leader, designs, manufactures, and distributes engines, filtration, and power generation products. With a history of over a century, Cummins has established a strong reputation for quality and innovation in the heavy-duty truck industry. The company’s product range includes various engines and components designed to meet the demanding requirements of commercial transportation, construction, and industrial applications 9.

Role of Part 3921836 Air Intake Connection in Engine Systems

The 3921836 Air Intake Connection is a vital component in the engine’s air intake system, ensuring the smooth and efficient transfer of air from the air filter to the throttle body or intake manifold. This connection is crucial for maintaining a clean and metered air supply, which is fundamental for optimal engine performance and fuel efficiency 10.

Conclusion

The 3921836 Air Intake Connection by Cummins is a versatile and essential component that plays a significant role in the efficiency and performance of heavy-duty truck engines. Its design, compatibility, and integration into various engine models make it a valuable asset for fleet operators and maintenance professionals.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5504181.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021).

↩ -

Heywood, J. (2019).

↩ -

Cummins Inc. (n.d.).

↩ -

Heywood, J. (2019).

↩ -

Cummins Inc. (n.d.).

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.