This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

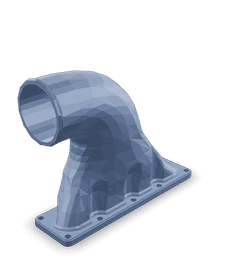

The Air Intake Hose Connector, identified by part number 3943750, is a component manufactured by Cummins, a prominent entity in the automotive and heavy-duty truck industry. This Cummins part plays a significant role in the air intake system of heavy-duty trucks, facilitating the efficient flow of air to the engine. Cummins is renowned for its commitment to innovation, quality, and performance, making this part a reliable choice for truck operators and maintenance professionals.

Function and Operation

The Air Intake Hose Connector operates within the truck’s air intake system by securely joining the air intake hose to the engine’s air intake port. Its primary role is to direct a steady flow of air from the intake hose to the engine, ensuring that the combustion process receives the necessary oxygen for efficient operation. The connector is designed to withstand the pressures and temperatures encountered in the air intake system, maintaining a secure seal to prevent air leaks that could affect engine performance 1.

Key Features

The design and construction of the Air Intake Hose Connector are tailored to enhance its performance and durability. It is typically made from high-quality materials that offer resistance to wear, corrosion, and the extreme conditions found in heavy-duty truck environments. The connector features a robust construction with precise fitting mechanisms, such as clamps or quick-connect systems, to ensure a secure and leak-free connection. Additionally, its design may include features that facilitate easy installation and removal, contributing to its overall effectiveness and longevity 2.

Benefits

The Air Intake Hose Connector contributes to improved engine performance by ensuring a consistent and unrestricted airflow to the engine. This can lead to enhanced fuel efficiency, as the engine operates more efficiently with a proper air-fuel mixture. Furthermore, by maintaining optimal airflow, the connector helps in reducing emissions, aligning with environmental regulations and promoting cleaner operation of heavy-duty trucks 3.

Installation and Compatibility

Proper installation of the Air Intake Hose Connector is crucial for its effective operation. It should be fitted according to the manufacturer’s guidelines, ensuring that all connections are secure and that the connector is compatible with the specific make and model of the truck. Attention to detail during installation helps prevent air leaks and ensures that the connector functions as intended within the air intake system.

Maintenance and Troubleshooting

To ensure the optimal performance of the Air Intake Hose Connector, regular maintenance is recommended. This includes inspecting the connector for signs of wear, damage, or leaks, and cleaning it as necessary to remove any debris that could obstruct airflow. If issues arise, such as air leaks or difficulty in connecting the hose, troubleshooting steps may involve checking for proper alignment, ensuring the connection mechanisms are functioning correctly, and replacing the connector if it is damaged or worn.

Safety Considerations

When working with the Air Intake Hose Connector, it is important to follow safety precautions to minimize risks. This includes wearing appropriate personal protective equipment, ensuring the engine is off and cool before beginning any work, and handling the connector with care to avoid injury or damage. Proper storage and disposal of the connector, following environmental guidelines, are also important considerations.

Environmental Impact

The production, use, and disposal of the Air Intake Hose Connector have environmental implications. Efforts to minimize its ecological footprint include using recyclable materials in its construction, designing for longevity to reduce the frequency of replacements, and ensuring that disposal practices are environmentally responsible. Cummins is committed to promoting sustainable practices throughout its product lifecycle.

Cummins Overview

Cummins, the manufacturer of the Air Intake Hose Connector, has a rich history of innovation and quality in the automotive industry. Founded in 1919, Cummins has grown to become a global leader in diesel engines, natural gas engines, and powertrain-related components. The company’s product offerings extend beyond engines to include filtration, emissions solutions, and aftermarket parts, all designed with a focus on performance, reliability, and sustainability. Cummins’ commitment to innovation is evident in its continuous investment in research and development, aiming to meet the evolving needs of the transportation industry.

Compatibility with Cummins Engines

The Air Intake Hose Connector part number 3943750, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is crucial for ensuring a proper seal and efficient airflow within the engine’s intake system. Here is a detailed look at its compatibility with various Cummins engines:

ISC CM554 and ISL CM554 Engines

The ISC CM554 and ISL CM554 engines are part of Cummins’ lineup of medium-duty diesel engines. These engines are known for their robust performance and reliability, often used in a variety of applications from vocational to commercial use. The Air Intake Hose Connector 3943750 is specifically engineered to fit these engines, ensuring that the intake system maintains its integrity and efficiency. This part is essential for connecting the air intake hose to the engine’s intake manifold, facilitating a smooth and uninterrupted flow of air.

QSC8.3 CM554 and QSL9 CM554 Engines

The QSC8.3 CM554 and QSL9 CM554 engines are part of Cummins’ heavy-duty diesel engine series. These engines are designed for demanding applications, providing high power output and durability. The Air Intake Hose Connector 3943750 is also compatible with these engines, ensuring that the intake system is properly sealed and efficient. This part is critical in maintaining the performance and reliability of these heavy-duty engines, as it connects the air intake hose to the engine’s intake manifold, ensuring a consistent and reliable air supply.

Role of Part 3943750 Air Intake Hose Connector in Engine Systems

The Part 3943750 Air Intake Hose Connector is a vital component in the air intake system of various engine setups. It facilitates a secure and efficient connection between the air intake hose and other components, ensuring optimal airflow into the engine.

Air Intake System Integration

In the air intake system, the Air Intake Hose Connector serves as a pivotal link. It connects the air intake hose to the throttle body or the mass airflow (MAF) sensor housing. This connection is vital for maintaining a sealed pathway for air to travel from the outside environment into the engine’s combustion chambers.

Connection to Throttle Body

When connected to the throttle body, the Air Intake Hose Connector ensures that the air, after being measured by the MAF sensor, flows smoothly into the throttle body. This setup allows for precise control over the air volume entering the engine, which is essential for maintaining the correct air-fuel ratio.

Interface with MAF Sensor Housing

In systems where the MAF sensor is located within the air intake hose, the Air Intake Hose Connector plays a role in securing the hose to the sensor housing. This connection is important for accurate air measurement, as any leaks or disruptions in the airflow can lead to incorrect readings by the MAF sensor, affecting engine performance.

Ensuring System Integrity

The Air Intake Hose Connector is designed to create a tight seal, preventing air leaks that could introduce unmetered air into the engine. This is important for maintaining the integrity of the air intake system and ensuring that the engine operates efficiently.

Contribution to Engine Performance

By providing a reliable connection in the air intake system, the Air Intake Hose Connector contributes to overall engine performance. It helps in delivering a consistent airflow, which is necessary for stable combustion and optimal engine output.

Conclusion

The Air Intake Hose Connector, part number 3943750, is a critical component in the air intake systems of Cummins engines, ensuring efficient airflow and system integrity. Its design and construction are tailored to withstand the demanding conditions of heavy-duty truck environments, contributing to improved engine performance, fuel efficiency, and reduced emissions. Proper installation, maintenance, and adherence to safety considerations are essential for maximizing the benefits of this Cummins part.

-

Drozdziel, Pawel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩ -

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Watson, Ben. Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.