This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

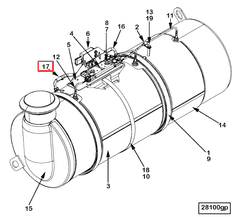

Understanding the Cummins Part #2888087 Air Tube: A Comprehensive Guide

Introduction to Air Tubes in Commercial Trucks

Air tubes are essential components in commercial truck engines, serving as conduits for air flow from the intake system to the engine cylinders. These tubes play a critical role in ensuring that the engine receives a consistent and clean supply of air, which is vital for combustion and overall engine performance. Without properly functioning air tubes, engines can suffer from reduced efficiency, increased emissions, and potential damage due to inadequate air-fuel mixture 1.

Role of the Cummins Part #2888087 Air Tube

The Cummins Part #2888087 air tube is a specialized component designed to enhance the air delivery system in Cummins engines. This air tube is engineered to provide a direct and unobstructed path for air to travel from the intake manifold to the turbocharger or intercooler. Its primary function is to ensure that the air entering the engine is clean, cool, and pressurized, which contributes to more efficient combustion and improved engine performance. By maintaining optimal air flow, the #2888087 air tube helps in maximizing the engine’s power output and fuel efficiency 2.

Cummins: A Leader in Engine Technology

Cummins is renowned in the industry for its commitment to quality and innovation in engine technology. The company’s reputation is built on a legacy of producing reliable and high-performance engine parts. Using genuine Cummins parts, such as the #2888087 air tube, ensures that truck engines operate at their best. Cummins’ dedication to rigorous testing and continuous improvement means that their parts are designed to meet the demanding requirements of commercial trucking, providing durability, efficiency, and long-term reliability 3.

Operational Insights of the Air Tube

The Cummins #2888087 air tube operates by guiding air from the intake system through a series of precisely engineered pathways. This air is often filtered to remove contaminants before it reaches the engine. The design of the air tube ensures minimal resistance to air flow, which is crucial for maintaining engine efficiency. Proper functioning of the air tube allows for optimal air-fuel mixing, leading to more complete combustion and reduced emissions. Regular maintenance of the air tube is essential to prevent blockages and ensure consistent engine performance 4.

Troubleshooting Common Issues

Identifying a faulty air tube can be critical in maintaining engine health. Common signs of air tube issues include reduced engine performance, unusual noises from the engine, and increased fuel consumption. To troubleshoot air tube problems, start by inspecting the tube for visible damage, such as cracks or leaks. Use a pressure gauge to check for proper air flow and look for any signs of obstruction within the tube. Addressing these issues promptly can prevent more severe engine problems and ensure continued efficiency.

Maintenance Tips for Air Tubes

Regular inspection and maintenance of the air tube are vital for longevity and performance. Mechanics should establish a routine for checking the air tube during regular service intervals. This includes visual inspections for damage, cleaning the tube to remove any buildup, and ensuring all connections are secure. Additionally, checking for leaks and verifying proper air flow can help identify potential issues before they become critical. Replacing the air tube when signs of wear or damage are detected is crucial for maintaining optimal engine performance.

Expert Insights and Best Practices

Experienced mechanics and engineers emphasize the importance of integrating air tube maintenance into regular fleet operations. Tips from the field include keeping a log of air tube inspections and replacements, using high-quality replacement parts, and training staff on the importance of air tube care. Real-world examples often show that neglecting air tube maintenance can lead to significant engine issues, highlighting the need for proactive care. By following best practices and leveraging expert insights, fleets can ensure their engines remain efficient and reliable.

Role of Part 2888087 Air Tube in Aftertreatment Device Systems

In the context of aftertreatment systems, part 2888087 Air Tube serves as a vital conduit for the regulated flow of exhaust gases. This component is integral to the efficient operation of several key elements within the aftertreatment device, ensuring that emissions are managed effectively before they are released into the atmosphere.

Integration with Diesel Particulate Filters (DPF)

The Air Tube facilitates the passage of exhaust gases to the Diesel Particulate Filter (DPF). By maintaining a consistent flow, it allows the DPF to capture particulate matter efficiently. This is essential for reducing the emission of harmful particles, contributing to cleaner exhaust outputs.

Contribution to Selective Catalytic Reduction (SCR) Systems

In Selective Catalytic Reduction (SCR) systems, the Air Tube plays a role in directing exhaust gases to the SCR catalyst. This ensures that the gases are properly mixed with the reductant (typically urea), promoting the conversion of nitrogen oxides (NOx) into harmless nitrogen and water vapor. The precise flow managed by the Air Tube is key to the effectiveness of the SCR process.

Support for Diesel Oxidation Catalysts (DOC)

The Air Tube also aids in the functioning of Diesel Oxidation Catalysts (DOC). By ensuring a steady stream of exhaust gases reaches the DOC, it supports the catalyst’s role in oxidizing carbon monoxide (CO) and hydrocarbons (HC) into carbon dioxide (CO2) and water (H2O). This contributes to lower overall emissions from the engine.

Enhancement of Overall System Efficiency

Beyond individual components, the Air Tube enhances the overall efficiency of the aftertreatment system. It ensures that exhaust gases are directed through the system in an optimal manner, minimizing backpressure and maximizing the performance of each aftertreatment component. This results in a more effective reduction of emissions and improved engine performance.

Conclusion

The Cummins Part #2888087 air tube is a critical component in the engine system of commercial trucks, playing a vital role in maintaining engine efficiency and performance. Proper maintenance and timely troubleshooting are essential to ensure the air tube functions correctly. Utilizing genuine Cummins parts and following expert maintenance tips can help fleets achieve reliable and optimal engine performance. Emphasizing the importance of air tube care contributes to the overall longevity and efficiency of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.