This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3911737 Air Tube is a component designed for use in commercial trucks, specifically within their air systems. This part facilitates the efficient operation of the truck by managing the flow of air, which is vital for various functions including braking and suspension systems 3.

Basic Concepts of Air Tubes

Air tubes are integral components in a truck’s air system, responsible for transporting compressed air from the compressor to various parts of the vehicle that require it. These tubes ensure that air reaches its destination with minimal loss of pressure, which is crucial for maintaining the efficiency and reliability of the air-operated systems in the truck 1.

Purpose of the Cummins 3911737 Air Tube

The Cummins 3911737 Air Tube is designed to direct and regulate the flow of air within the truck’s air system. It plays a role in ensuring that air is distributed effectively to components such as the brakes and suspension, contributing to the overall performance and safety of the vehicle 3.

Key Features

The 3911737 Air Tube is constructed with durability and performance in mind. It is made from high-quality materials that resist wear and corrosion, ensuring longevity in demanding environments. Its design includes features that enhance airflow efficiency and reduce the risk of leaks, contributing to the reliability of the truck’s air system 2.

Benefits of Using the Cummins 3911737 Air Tube

Utilizing the Cummins 3911737 Air Tube in a truck’s air system offers several advantages. These include improved system efficiency due to optimized airflow, enhanced durability that reduces the need for frequent replacements, and increased reliability, which is critical for the safe operation of commercial vehicles 3.

Installation and Integration

Installing the Cummins 3911737 Air Tube involves connecting it to the existing air system components, following manufacturer guidelines to ensure a secure and efficient fit. Proper installation is key to maximizing the performance benefits of this component and integrating it seamlessly into the truck’s air system 1.

Maintenance and Care

To ensure the Cummins 3911737 Air Tube continues to perform optimally, regular maintenance is recommended. This includes inspecting the tube for signs of wear or damage, cleaning it to remove any debris that could obstruct airflow, and checking connections for leaks. Adhering to a maintenance schedule helps in identifying potential issues before they lead to system failures 2.

Troubleshooting Common Issues

Common issues with air tubes, such as leaks or blockages, can affect the performance of the truck’s air system. Troubleshooting these problems involves inspecting the tube and connections for damage, ensuring all fittings are secure, and clearing any obstructions within the tube. Addressing these issues promptly helps maintain the efficiency and reliability of the air system 3.

Compatibility and Usage

The Cummins 3911737 Air Tube is designed for use in specific types of trucks and air systems. It is important to verify compatibility with the vehicle’s make and model to ensure proper function and integration. Usage guidelines provided by the manufacturer should be followed to maximize the benefits of this component 1.

Manufacturer Information - Cummins

Cummins is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins continues to be a trusted name among professionals in the field, offering products that meet the demanding requirements of commercial vehicle operations 2.

Cummins Air Tube Part 3911737 in Engine Applications

The Cummins Air Tube part number 3911737 is a critical component in the air intake system of several engine models. This part is designed to ensure that the engine receives a consistent and clean air supply, which is essential for optimal performance and efficiency 3.

Application in Cummins Engines

-

4B3.9 Engine: The 4B3.9 engine utilizes the 3911737 Air Tube to facilitate the flow of air from the intake manifold to the turbocharger. This part is integral in maintaining the pressure and temperature balance required for the engine’s combustion process.

-

Other Cummins Engines: While the 4B3.9 is a notable example, the 3911737 Air Tube is also compatible with other Cummins engines within the same engine family. These engines share similar design principles and requirements for air intake, making the part interchangeable across various models.

Importance of the Air Tube

The air tube’s role in the engine’s air intake system cannot be overstated. It ensures that the air entering the engine is free from contaminants and is at the correct pressure. This is crucial for the engine’s performance, as it directly affects the combustion process and overall efficiency 1.

Installation and Maintenance

Proper installation of the 3911737 Air Tube is essential to avoid any disruptions in the air flow, which could lead to performance issues. Regular maintenance checks should be performed to ensure that the air tube is free from cracks, leaks, or obstructions. Any damage to the air tube can compromise the engine’s air intake system, leading to decreased performance and potential engine damage 2.

Compatibility and Interchangeability

The 3911737 Air Tube is designed to be compatible with various Cummins engine models. This interchangeability is beneficial for maintenance and repair purposes, as it allows for a standardized part to be used across multiple engine types, simplifying inventory management and reducing downtime 3.

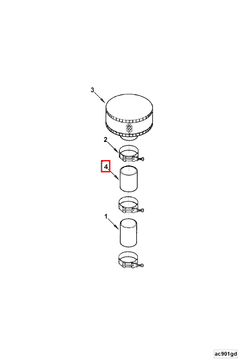

Role of Part 3911737 Air Tube in Engine Systems

The 3911737 Air Tube is integral to the efficient operation of engine systems, particularly in managing airflow to and from various components. This component facilitates the movement of air between the air cleaner and other engine parts, ensuring optimal performance and reliability 1.

Air Cleaner Integration

The air cleaner is the first line of defense in protecting the engine from contaminants. The 3911737 Air Tube connects the air cleaner to the intake manifold, allowing clean, filtered air to enter the engine. This connection is vital for maintaining the engine’s efficiency and longevity, as it ensures that only clean air, free from dust and debris, is drawn into the combustion chambers 2.

Airflow Management

Beyond the air cleaner, the 3911737 Air Tube plays a significant role in managing airflow throughout the engine system. It helps regulate the pressure and volume of air entering the engine, which is essential for proper fuel combustion. Efficient airflow management contributes to better fuel economy and reduced emissions, making the engine more environmentally friendly and cost-effective to operate 3.

Enhanced Engine Performance

By ensuring a consistent and clean air supply, the 3911737 Air Tube supports the engine’s overall performance. It helps maintain the correct air-fuel ratio, which is crucial for maximizing power output and ensuring smooth operation. This component also aids in reducing the risk of engine knocking and other performance issues that can arise from improper airflow 1.

Reliability and Durability

The 3911737 Air Tube is designed to withstand the high pressures and temperatures within the engine compartment. Its robust construction ensures long-lasting performance, minimizing the need for frequent replacements or repairs. This reliability is essential for maintaining the engine’s uptime and reducing maintenance costs 2.

Conclusion

In summary, the 3911737 Air Tube is a key component in the engine system, facilitating efficient airflow from the air cleaner to the intake manifold. Its role in maintaining clean air supply, managing airflow, enhancing engine performance, and ensuring reliability makes it an indispensable part of modern engine designs 3.

-

Diesel Engine Combustion, Emissions and Condition Monitoring, Saiful Bari, InTech, 2013.

↩ ↩ ↩ ↩ ↩ ↩ -

Understanding Automotive Electronics, William B. Ribbens, Elsevier Science, 2003.

↩ ↩ ↩ ↩ ↩ ↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.