This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

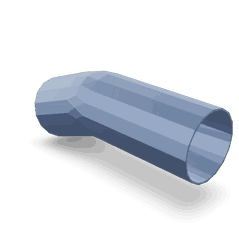

The Cummins 3914942 Air Tube is a component designed for use in commercial trucks, playing a role in the vehicle’s air system. This part is manufactured by Cummins, a company known for its extensive range of diesel engines and related components, which are widely used in the commercial trucking industry. Cummins has established a reputation for producing reliable and high-performance parts, and the 3914942 Air Tube is no exception 1.

Basic Concepts of Air Tubes

An air tube in a truck’s air system serves as a conduit for compressed air, which is used to operate various components such as brakes, suspension systems, and other pneumatic devices. The efficiency and performance of these components depend on the consistent and reliable delivery of compressed air. Air tubes are integral to maintaining the overall performance and efficiency of the vehicle by ensuring that air-operated systems receive the necessary air pressure to function correctly 2.

Purpose and Function of the 3914942 Air Tube

The 3914942 Air Tube is specifically designed to facilitate the distribution of compressed air within a truck’s air system. It connects to various components, ensuring that they receive the air pressure needed for operation. This includes critical systems like the brakes and suspension, where consistent air pressure is vital for safety and performance. By providing a reliable pathway for air, the 3914942 Air Tube contributes to the efficient operation of these systems 3.

Key Features

The design and construction of the 3914942 Air Tube incorporate several features that enhance its durability, efficiency, and reliability. Constructed from high-quality materials, this air tube is built to withstand the pressures and conditions typical in commercial truck operations. Its design may include reinforced sections to prevent kinking and ensure a smooth flow of air. These features contribute to the tube’s performance and longevity in demanding environments 4.

Benefits of Using the 3914942 Air Tube

Incorporating the 3914942 Air Tube into a truck’s air system offers several advantages. Improved airflow efficiency can lead to better performance of air-operated components. The tube’s durable construction reduces the need for frequent maintenance, contributing to lower overall costs. Additionally, the reliability of the 3914942 Air Tube enhances the dependability of the truck’s air system, potentially leading to cost savings over time through reduced downtime and repair needs 5.

Installation Considerations

When installing the 3914942 Air Tube, it is important to follow guidelines and best practices to ensure proper fit and function within the air system. Compatibility with various truck models should be verified, and the necessary tools should be on hand. Careful attention to the installation process helps ensure that the air tube operates as intended, contributing to the overall efficiency and reliability of the truck’s air system 6.

Troubleshooting Common Issues

Common problems associated with air tubes, including the 3914942 model, may include leaks, blockages, and performance declines. Diagnostic tips for identifying these issues can involve checking for visible signs of damage or wear, listening for unusual noises that may indicate a leak, and monitoring the performance of air-operated components. Potential solutions may range from simple repairs or adjustments to replacement of the air tube if necessary 7.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the 3914942 Air Tube. This may include routine inspections for signs of wear or damage, cleaning the tube to remove any debris that could obstruct airflow, and monitoring the overall condition of the truck’s air system. Knowing when to consider replacement is also important, as worn or damaged air tubes can affect the performance of air-operated components 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has earned a reputation for producing reliable and high-performance components for the commercial truck industry. The company’s dedication to excellence is reflected in its product range and the trust it has built among customers and industry professionals 9.

Cummins Air Tube Part 3914942 Compatibility

The Cummins Air Tube part number 3914942 is designed to fit seamlessly with several engine models, ensuring optimal performance and efficiency. This part is integral in maintaining the air flow within the engine system, which is crucial for the engine’s operation.

Compatible Engines

- 6C8.3

The 3914942 Air Tube is specifically engineered to integrate with the 6C8.3 engine. Its design ensures that it fits precisely, providing a reliable connection between various components of the engine’s air intake system. This compatibility is essential for maintaining the engine’s performance and longevity.

Engine Grouping

In broader terms, the 3914942 Air Tube is part of a series of components designed to work with multiple Cummins engine models. This part is crafted to meet the stringent requirements of Cummins engines, ensuring that it fits snugly and functions as intended within the engine’s architecture. The design and material of the air tube are chosen to withstand the operational stresses and environmental conditions that Cummins engines typically encounter.

By ensuring a proper fit and function, the 3914942 Air Tube contributes to the overall efficiency and reliability of the engine systems it is designed to support 10.

Understanding the Role of Part 3914942 Air Tube in Engine Systems

Part 3914942, an Air Tube, is integral to the efficient operation of various engine components. Its primary function is to facilitate the smooth and controlled flow of air within the engine system, ensuring optimal performance and reliability.

Integration with Turbocharger Systems

In turbocharger arrangements, the Air Tube plays a significant role. It is responsible for directing compressed air from the turbocharger to the engine’s intake system. This ensures that the air entering the combustion chamber is at the correct pressure and temperature, which is essential for maximizing engine efficiency and power output.

Turbocharger Arrangement and Location

The placement of the turbocharger within the engine bay can vary, and the Air Tube must be configured accordingly. Whether the turbocharger is positioned on the exhaust side or integrated into a twin-turbo setup, the Air Tube must be precisely routed to avoid interference with other components while maintaining a secure and leak-free connection.

Enhancing Engine Performance

By ensuring a consistent and regulated airflow, Part 3914942 contributes to the overall performance of the engine. It helps in reducing turbo lag, improving throttle response, and enhancing the engine’s ability to deliver power across a broader range of operating conditions.

Supporting Engine Durability

The Air Tube also plays a part in protecting the engine from potential damage. By providing a dedicated pathway for air, it helps prevent the ingestion of contaminants that could otherwise lead to wear and tear on critical engine components.

Conclusion

In summary, the 3914942 Air Tube is a vital component in modern engine systems, particularly those equipped with turbochargers. Its role in managing airflow is essential for maintaining engine performance, efficiency, and durability.

-

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Sclar, Deanna. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388786, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388786, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388786, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388786, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388786, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388786, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388786, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.