This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The AR10096 Air Compressor Support is a component designed to enhance the operation of commercial trucks by providing structural support to the air compressor. This part is integral to the air brake system, ensuring efficient and reliable performance. Cummins, a well-respected manufacturer in the automotive industry, produces this component. Known for their commitment to quality and innovation, Cummins provides solutions that meet the demanding requirements of commercial trucking 1.

Basic Concepts of Air Compressor Support

An Air Compressor Support serves to secure the air compressor within the truck’s chassis. This support is vital for the proper functioning of the air brake system, which relies on consistent and reliable air pressure to operate effectively. By maintaining the compressor in a fixed position, the support helps prevent excessive movement that could lead to wear and tear, ensuring the system’s integrity and contributing to the overall safety and performance of the truck 2.

Purpose of the AR10096 Air Compressor Support

The AR10096 Air Compressor Support plays a role in the operation of a truck by providing a stable mounting point for the air compressor. This stability is crucial for maintaining the alignment and efficiency of the compressor, which in turn supports the consistent delivery of compressed air needed for the brake system. By securing the compressor, the support helps maintain system integrity, reducing the risk of compressor failure and ensuring reliable brake performance 3.

Key Features

The AR10096 Air Compressor Support is constructed from durable materials, designed to withstand the rigors of commercial truck operation. Its design includes features such as reinforced mounting points and corrosion-resistant coatings, which enhance its performance and longevity. These attributes ensure that the support can endure the vibrations and environmental conditions encountered on the road, providing reliable service over the vehicle’s lifespan 4.

Benefits

The AR10096 Air Compressor Support offers several benefits to fleet operators. By providing a secure and stable mounting solution for the air compressor, it contributes to improved reliability and performance of the brake system. This can lead to enhanced safety on the road, as well as potential cost savings through reduced maintenance and repair needs. The durability and design of the support also mean that it requires minimal maintenance, further adding to its value for fleet operations.

Installation Process

Installing the AR10096 Air Compressor Support involves several steps to ensure a secure fit. Begin by locating the designated mounting points on the truck’s chassis. Use the appropriate tools to attach the support, ensuring that all bolts are tightened to the manufacturer’s specifications. It is important to verify that the support is level and securely fastened to prevent any movement that could affect the compressor’s performance. Following these steps will help ensure that the support is installed correctly, providing the intended benefits to the truck’s air brake system.

Troubleshooting Common Issues

Common issues with the AR10096 Air Compressor Support may include loose mounting bolts or corrosion on the support structure. To address these problems, first, inspect the mounting points for any signs of wear or corrosion. Tighten any loose bolts to the specified torque settings to ensure a secure fit. If corrosion is present, clean the affected areas and apply a corrosion-resistant coating to prevent further degradation. Regular inspections can help identify these issues early, allowing for timely corrections and maintaining the support’s effectiveness.

Maintenance Tips

To ensure the longevity and optimal performance of the AR10096 Air Compressor Support, regular maintenance is recommended. Inspect the support and its mounting points during routine vehicle checks, looking for signs of wear, corrosion, or looseness. Clean the support as needed to remove any dirt or debris that could affect its performance. Applying a corrosion-resistant coating periodically can also help protect the support from environmental damage. Following these maintenance practices will help maintain the support’s condition and ensure reliable operation of the air brake system.

Cummins: A Brief Overview

Cummins is a renowned manufacturer with a long-standing reputation in the automotive industry. Established with a focus on innovation and quality, Cummins has built a portfolio of high-performance components designed to meet the needs of commercial trucking. Their commitment to excellence is evident in the durability, reliability, and performance of their products, making them a trusted name among fleet operators and maintenance professionals.

Cummins AR10096 Air Compressor Support in Engine Applications

The Cummins AR10096 Air Compressor Support is a critical component designed to ensure the stability and efficiency of the air compressor system in various engine configurations. This part is integral to the operation of the engines, providing necessary support and alignment to maintain optimal performance.

K19 and QSK19 Engines

In the K19 and QSK19 engines, the AR10096 Air Compressor Support plays a pivotal role in maintaining the structural integrity of the air compressor. This support ensures that the compressor operates smoothly, reducing wear and tear on the engine components. The precision engineering of the AR10096 guarantees that the air compressor remains aligned, which is crucial for the efficient delivery of compressed air to the engine’s combustion system.

CM500 Engine

For the CM500 engine, the AR10096 Air Compressor Support is equally essential. This engine, known for its robust performance, relies on the AR10096 to maintain the air compressor’s position and alignment. The support helps in distributing the forces exerted during operation, thereby extending the lifespan of the air compressor and other related components. The design of the AR10096 ensures that the air compressor can withstand the high pressures and temperatures typical of the CM500 engine’s operation.

Grouping of Engines

The K19 and QSK19 engines, while distinct in their specific applications, share common design philosophies and operational requirements. The AR10096 Air Compressor Support is engineered to meet the demands of both these engines, providing a reliable solution for maintaining the air compressor’s integrity. Similarly, the CM500 engine, with its unique operational characteristics, also benefits from the robust design of the AR10096, ensuring that the air compressor operates efficiently and reliably under demanding conditions.

Role of Part AR10096 Air Compressor Support in Engine Systems

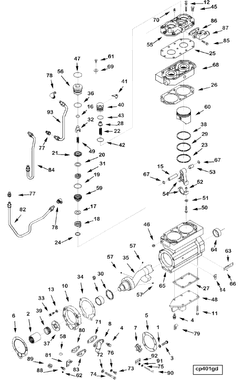

The AR10096 Air Compressor Support is an essential component in the assembly and functionality of various air compressor systems, including the air 2-cylinder compressor and general air compressor units. This support structure is designed to provide stability and secure mounting for the compressor, ensuring optimal performance and longevity of the compressor unit.

Integration with Air 2-Cylinder Compressor

In the air 2-cylinder compressor system, the AR10096 support plays a significant role by:

- Stabilizing the Compressor: It ensures that the dual-cylinder compressor remains firmly in place, reducing vibrations and enhancing the efficiency of the compression process.

- Facilitating Heat Dissipation: By securely holding the compressor, it allows for better airflow around the unit, which is vital for effective heat management.

- Supporting Additional Components: It often serves as a mounting point for other components such as hoses, filters, and regulators, contributing to a more organized and efficient system layout.

Function in General Air Compressor Systems

For general air compressor units, the AR10096 support offers:

- Enhanced Durability: By providing a robust mounting solution, it helps in withstanding the operational stresses that compressors undergo, leading to a longer service life.

- Simplified Maintenance: The secure mounting allows for easier access to the compressor for routine checks and maintenance, reducing downtime.

- Versatility in Application: Its design accommodates various compressor sizes and types, making it a versatile component in different air compressor setups.

Overall Impact on Compressor Performance

The AR10096 Air Compressor Support is integral to maintaining the structural integrity and operational efficiency of air compressor systems. Its role in stabilizing the compressor, aiding in heat dissipation, and supporting additional components ensures that the compressor operates smoothly and reliably. This, in turn, contributes to the overall performance and durability of the engine system in which it is installed.

Conclusion

The AR10096 Air Compressor Support is a vital component in the operation of commercial trucks and various engine systems. Its design and features ensure the stability and efficiency of the air compressor, contributing to the overall performance and safety of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, ensuring reliable and efficient operation of the air brake system and engine components.

-

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩ -

Boger, Thorsten, and Willard Cutler. Reducing Particulate Emissions in Gasoline Engines. SAE International, 2018.

↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.