This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

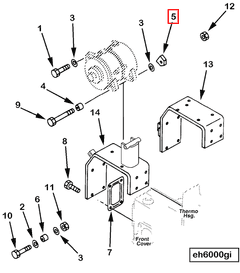

The 3092444 Alternator Mounting Nut, manufactured by Cummins, is a critical component in the commercial truck industry. This part is designed to secure the alternator to the engine, ensuring stability during operation. Cummins, renowned for its quality and innovation, produces this part to meet the demanding requirements of commercial truck applications 1.

Purpose and Function

The primary function of the 3092444 Alternator Mounting Nut is to secure the alternator to the engine. This secure attachment is essential for the stable operation of the alternator, which ensures the reliable functioning of the truck’s electrical system. By maintaining a firm connection, the nut prevents vibrations and movement that could lead to electrical issues or alternator failure 2.

Key Features

The 3092444 Alternator Mounting Nut is engineered with specific design and material characteristics to enhance its performance and longevity. It features a precise thread size for a snug fit with the alternator and engine components. The nut is made from durable materials that can withstand the harsh conditions typical of commercial truck environments. Additionally, it may include special coatings or treatments that provide extra resistance to corrosion and wear, further extending its service life 3.

Benefits

Using the 3092444 Alternator Mounting Nut offers several advantages. It provides a reliable means of attaching the alternator, contributing to the overall stability and efficiency of the electrical system. The nut’s resistance to corrosion ensures it maintains its integrity over time, even in challenging operating conditions. Furthermore, its design allows for ease of installation, reducing the time and effort required during maintenance or replacement procedures.

Installation Process

Proper installation of the 3092444 Alternator Mounting Nut is crucial for ensuring optimal performance and safety. The process involves aligning the nut with the corresponding threads on the alternator and engine, then tightening it to the specified torque. Adhering to the recommended torque specifications is important to avoid over-tightening, which could damage the threads, or under-tightening, which could lead to a loose connection. Correct installation ensures that the alternator is securely fastened, contributing to the reliable operation of the truck’s electrical system.

Maintenance and Troubleshooting

Regular maintenance of the 3092444 Alternator Mounting Nut is important to ensure its continued performance. This includes periodic inspections for signs of loosening, corrosion, or damage. If the nut shows signs of wear or if it becomes loose, it should be tightened or replaced as necessary. Addressing these issues promptly helps prevent more significant problems, such as alternator failure or electrical system malfunctions.

Compatibility and Application

The 3092444 Alternator Mounting Nut is designed for use with specific types of trucks and alternators. It is important to use manufacturer-recommended parts to ensure compatibility and optimal performance. Using the correct components helps maintain the integrity of the electrical system and ensures that the alternator operates efficiently.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality automotive components. With a history of innovation and a commitment to excellence, Cummins has established a reputation for producing reliable and durable parts. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial truck applications. Cummins’ dedication to quality and customer satisfaction underscores its position as a trusted provider in the industry.

Cummins Alternator Mounting Nut 3092444 Compatibility

The Cummins Alternator Mounting Nut part number 3092444 is designed to fit seamlessly with several engine models. This part is crucial for securing the alternator in place, ensuring that it operates correctly and efficiently. Here are the engines and engine groups where this part is compatible:

QST30 CM552 Engines

- QST30 CM552: This engine model is part of the Cummins QST series, known for its robust performance and reliability. The Alternator Mounting Nut 3092444 is specifically engineered to fit this engine, ensuring a secure and stable connection for the alternator.

Group Compatibility

-

Cummins QST Series: The 3092444 Alternator Mounting Nut is compatible with various engines within the Cummins QST series. This series is widely used in industrial and commercial applications due to its durability and efficiency. The part’s design ensures it fits perfectly with the mounting requirements of these engines.

-

Cummins CM552 Series: The CM552 engine is another model where the 3092444 Alternator Mounting Nut is applicable. This engine is known for its high power output and reliability, making it a popular choice in various sectors. The mounting nut ensures that the alternator is securely attached, preventing any movement that could affect engine performance.

By ensuring that the alternator is properly mounted, the 3092444 Alternator Mounting Nut contributes to the overall efficiency and longevity of the engine. This part is a critical component in maintaining the integrity of the alternator’s position, which is essential for the engine’s optimal operation.

Understanding the Role of Part 3092444 Alternator Mounting Nut in Engine Systems

The alternator mounting nut, identified by part number 3092444, is an essential component in the secure attachment of the alternator to the engine system. This nut is integral to the proper functioning of the alternator, which is responsible for generating electrical power to charge the battery and power the vehicle’s electrical systems while the engine is running.

When the alternator is mounted to the engine, the alternator mounting nut ensures a stable and vibration-resistant connection. This stability is important for the alternator’s performance, as any movement can lead to inefficient operation or even damage to the alternator or its associated components.

The alternator mounting nut works in conjunction with the alternator bracket, which is typically bolted to the engine block or the cylinder head. The nut is threaded onto a stud or bolt that passes through the alternator and the bracket, pulling the two components tightly together. This setup not only holds the alternator in place but also allows for the proper alignment of the alternator’s pulley with the serpentine belt, which drives the alternator.

In addition to its primary function, the alternator mounting nut also plays a role in the thermal management of the alternator. By providing a firm mount, it helps in dissipating heat generated by the alternator, which is important for maintaining optimal operating temperatures and prolonging the lifespan of the alternator.

Furthermore, the secure attachment facilitated by the alternator mounting nut is important during vehicle operation, especially under varying load conditions and speeds. It ensures that the alternator remains in the correct position, allowing for consistent power output and reliable electrical system performance.

In summary, the alternator mounting nut is a small but significant part that contributes to the overall efficiency and reliability of the vehicle’s electrical system by ensuring the alternator is properly and securely mounted to the engine.

Conclusion

The 3092444 Alternator Mounting Nut is a vital component in the commercial truck industry, ensuring the secure attachment of the alternator to the engine. Its precise design, durable materials, and resistance to corrosion contribute to the reliable operation of the truck’s electrical system. Proper installation, regular maintenance, and using manufacturer-recommended parts are essential for optimal performance and longevity. Cummins’ commitment to quality and innovation underscores the importance of this part in maintaining the efficiency and reliability of commercial truck applications.

-

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.