This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

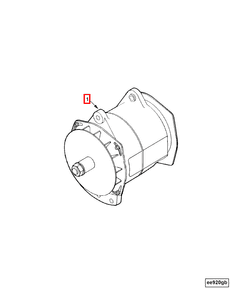

The Cummins 3279220 Alternator is a component designed for use in commercial trucks. It plays a significant role in the vehicle’s electrical system, ensuring that the truck operates efficiently and reliably. Understanding its function and significance is important for maintaining the overall performance of the truck.

Basic Concepts of Alternators

An alternator is a device that converts mechanical energy into electrical energy. It is a key component of a vehicle’s electrical system, responsible for generating the power needed to operate various electrical components and recharge the battery. The alternator works by using a rotor that spins within a stator, creating a magnetic field that induces an electrical current in the stator windings 1.

Purpose of the Cummins 3279220 Alternator

The Cummins 3279220 Alternator is specifically designed to maintain the electrical system of a truck. It ensures that the battery remains charged and provides the necessary power for the truck’s electrical components, such as lights, sensors, and communication systems. This alternator plays a role in supporting the truck’s electrical demands, contributing to its overall operational efficiency 2.

Key Features

The Cummins 3279220 Alternator is characterized by its robust design and construction. It is built using high-quality materials that enhance its durability and performance. Notable features include its compact design, which allows for easy installation, and its efficient cooling system, which helps maintain optimal operating temperatures 3.

Benefits

The Cummins 3279220 Alternator offers several advantages. It provides improved efficiency, ensuring that the electrical system operates at peak performance. Its durable construction contributes to a longer service life, reducing the need for frequent replacements. Additionally, it is designed to be compatible with Cummins engines, ensuring seamless integration and reliable operation.

Troubleshooting and Maintenance

Common issues with the Cummins 3279220 Alternator may include electrical faults or mechanical wear. Regular maintenance practices, such as checking the belt tension and inspecting the electrical connections, can help prevent these issues. If problems arise, troubleshooting steps may involve testing the electrical output and inspecting the alternator for signs of wear or damage.

Integration with Cummins Engines

The Cummins 3279220 Alternator is engineered to integrate seamlessly with Cummins engines. It features specific compatibility features that ensure it works efficiently with these engines. This integration helps maintain the electrical system’s reliability and contributes to the overall performance of the truck.

Performance in Heavy-Duty Applications

In heavy-duty truck applications, the Cummins 3279220 Alternator demonstrates robust performance. It is designed to withstand the demanding operating conditions typically encountered in commercial trucking, providing reliable electrical power even under strenuous conditions. Its ability to deliver consistent performance makes it a valuable component for heavy-duty applications.

Environmental Considerations

The Cummins 3279220 Alternator contributes to improved fuel efficiency and reduced emissions. By ensuring that the electrical system operates efficiently, it helps minimize the truck’s environmental footprint. Its design and performance characteristics are aligned with efforts to promote more sustainable and eco-friendly commercial vehicle operations.

Cummins Company Overview

Cummins Inc. is a renowned manufacturer of diesel engines and related technologies, including alternators, for commercial vehicles. With a rich history and a commitment to innovation, Cummins has established itself as a leader in the industry. The company’s mission is to power a more prosperous world, and its reputation for quality and reliability is well-deserved.

Cummins Alternator 3279220 Compatibility

The Cummins Alternator part number 3279220 is designed to be compatible with a variety of engine models, ensuring reliable power generation across different applications. Here is an overview of the engines with which this alternator is compatible:

6C8.3 Engine

The 6C8.3 engine is one of the models that can utilize the Cummins Alternator 3279220. This alternator is engineered to meet the specific electrical requirements of the 6C8.3 engine, ensuring optimal performance and longevity.

Group Compatibility

In addition to the 6C8.3 engine, the Cummins Alternator 3279220 is also compatible with other engines within the same group. This compatibility is due to the standardized design and specifications that ensure the alternator can effectively interface with the engine’s electrical system.

The compatibility of the 3279220 alternator with these engines is based on rigorous testing and validation, ensuring that it can handle the electrical load and provide consistent power output. This makes it a reliable choice for maintenance and replacement purposes across multiple engine models.

Role of Part 3279220 Alternator in Engine Systems

The alternator, specifically part 3279220, is a component in the engine system, responsible for generating electrical power to sustain the vehicle’s electrical systems while the engine is running. This power is vital for maintaining battery charge, powering the ignition system, and operating various electrical accessories such as lights, the radio, and the air conditioning system.

Interaction with Key Components

-

Battery: The alternator works in tandem with the battery to ensure a consistent power supply. It recharges the battery during engine operation, allowing the battery to provide the necessary power for starting the engine and supporting electrical systems when the engine is off.

-

Voltage Regulator: Integrated within or connected to the alternator, the voltage regulator maintains a stable output voltage, typically around 13.5 to 14.5 volts, to prevent overcharging or undercharging the battery.

-

Drive Belt: The alternator is driven by the engine’s crankshaft via a drive belt (often a serpentine belt). This mechanical connection allows the alternator to spin and generate electricity as the engine runs.

-

Electrical System: The alternator supplies power to the entire electrical system of the vehicle. This includes the ignition system, which requires a steady power supply to generate sparks for combustion, and various sensors and control modules that rely on consistent electrical power for accurate readings and operations.

-

Starter Motor: Although the starter motor is powered by the battery during engine start-up, a well-functioning alternator ensures the battery remains charged, enabling reliable starts even after prolonged idling or accessory use.

-

Lighting System: Headlights, taillights, and interior lights all draw power from the alternator when the engine is running, ensuring bright and reliable illumination.

-

Accessory Power: Modern vehicles have numerous electrical accessories, such as power windows, seats, and entertainment systems. The alternator provides the necessary power to operate these features smoothly.

-

Fuel Injection System: In fuel-injected engines, the alternator helps maintain the power needed for the fuel injection system to operate efficiently, ensuring precise fuel delivery and optimal engine performance.

By understanding the alternator’s role and its interactions with these components, engineers and mechanics can better diagnose issues, perform maintenance, and ensure the overall efficiency and reliability of the vehicle’s electrical system.

Conclusion

The Cummins 3279220 Alternator is a critical component in the electrical system of commercial trucks. Its robust design, efficient performance, and compatibility with Cummins engines make it a reliable choice for maintaining the electrical demands of heavy-duty applications. Regular maintenance and understanding its role within the engine system are essential for ensuring the truck’s overall performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.