This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3281534 Plain Hose Coupling Connector is a component manufactured by Cummins, designed to facilitate secure connections in fluid systems within commercial trucks. This connector plays a significant role in ensuring the efficient and safe operation of various truck systems by providing reliable fluid transfer. Cummins, a well-established manufacturer in the automotive industry, is known for producing high-quality components that enhance vehicle performance and durability.

Basic Concepts of Plain Hose Coupling Connectors

Plain hose coupling connectors are devices used to join hoses in fluid systems, allowing for the transfer of liquids or gases between different parts of the system. These connectors are vital in maintaining the integrity of hydraulic and fuel systems by ensuring that connections are secure and leak-free. The reliable operation of these systems depends on the connectors’ ability to withstand pressure, vibration, and environmental conditions, making their design and material critical factors in their performance 1.

Purpose and Role in Truck Operation

The 3281534 Plain Hose Coupling Connector is specifically designed to serve a crucial function in the operation of commercial trucks. It is used in various fluid systems, including hydraulic and fuel lines, to ensure that connections are both secure and reliable. By providing a consistent and leak-free connection, this connector contributes to the efficient operation of the truck’s systems, enhancing overall performance and safety. Its role in maintaining system integrity under varying operational conditions is significant, as it helps prevent fluid leaks that could lead to system failures or safety hazards 2.

Key Features

The 3281534 Plain Hose Coupling Connector features a design that includes robust materials and precise engineering to ensure durability and reliability. Constructed from high-quality materials, it is capable of withstanding the pressures and temperatures encountered in truck fluid systems. Its design incorporates elements that facilitate easy installation and secure connection, reducing the likelihood of leaks. Additionally, the connector may include features such as corrosion-resistant coatings or enhanced sealing mechanisms to further improve its performance and longevity.

Benefits

Using the 3281534 Plain Hose Coupling Connector offers several benefits, including improved reliability in fluid systems, ease of installation, and maintenance advantages. The connector’s design allows for quick and secure connections, minimizing downtime during maintenance or repairs. Its durability and resistance to corrosion contribute to the overall longevity of the truck’s fluid systems, reducing the need for frequent replacements. These benefits collectively enhance the truck’s performance and operational efficiency 3.

Installation and Usage

Proper installation of the 3281534 Plain Hose Coupling Connector is crucial for ensuring its effectiveness and longevity. Installation guidelines recommend following specific procedures to achieve a secure connection, including proper alignment and tightening to the manufacturer’s specifications. It is used in various truck systems, such as hydraulic and fuel lines, where secure and reliable connections are necessary for system operation. Adhering to installation best practices ensures that the connector performs as intended, contributing to the safe and efficient operation of the vehicle.

Troubleshooting and Maintenance

Common issues with plain hose coupling connectors may include leaks, corrosion, or wear due to operational stress. Troubleshooting steps involve inspecting the connector for signs of damage or wear, ensuring proper installation, and checking for compatibility with the system’s requirements. Maintenance tips include regular inspection for signs of wear or corrosion, cleaning the connector and surrounding areas, and replacing the connector if significant wear or damage is detected. These practices help ensure the longevity and optimal performance of the connector.

Safety Considerations

When installing and maintaining the 3281534 Plain Hose Coupling Connector, it is important to consider safety implications. Improper installation or maintenance can lead to fluid leaks, system failures, or safety hazards. Following manufacturer guidelines for installation and maintenance is crucial to ensure the connector’s effectiveness and safety. Additionally, using the correct tools and procedures during installation and maintenance helps prevent accidents and ensures the connector’s reliable operation.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, related technologies, and power generation equipment. With a history of innovation and quality, Cummins has established a reputation for producing reliable and high-performance components for the automotive and heavy-duty truck industries. Their expertise in manufacturing and commitment to quality ensure that their products, including the 3281534 Plain Hose Coupling Connector, meet the demanding requirements of commercial truck operations.

Cummins Engine Compatibility with Part 3281534

The Plain Hose Coupling Connector, part number 3281534, manufactured by Cummins, is a versatile component designed to fit seamlessly with several of their engine models. This part is essential for maintaining the integrity of the engine’s cooling and fuel systems by ensuring secure and leak-free connections.

Engine Compatibility

-

4B3.9 and 6B5.9 Engines The Plain Hose Coupling Connector is compatible with both the 4B3.9 and 6B5.9 engines. These engines are part of Cummins’ lineup that is known for its robust performance and reliability in various applications. The connector’s design ensures it fits perfectly with the hoses and pipes used in these engines, providing a reliable connection that can withstand the operational stresses.

-

6C8.3 and C8.3 G Engines The 6C8.3 and C8.3 G engines also benefit from the use of the Plain Hose Coupling Connector. These engines are typically used in heavy-duty applications, where durability and efficiency are paramount. The connector’s design is such that it can handle the high-pressure environments these engines operate in, ensuring that the hoses remain securely attached and do not fail under pressure.

Application and Benefits

The Plain Hose Coupling Connector is engineered to provide a simple yet effective solution for hose connections in engine systems. Its compatibility with multiple engine models makes it a valuable component for maintenance and repair operations. By ensuring a secure fit, this connector helps prevent leaks and system failures, contributing to the overall reliability and performance of the engine.

Role of Part 3281534 Plain Hose Coupling Connector in Engine Systems

The Part 3281534 Plain Hose Coupling Connector is integral to the fluid dynamics within engine systems, ensuring seamless and efficient operation of various components.

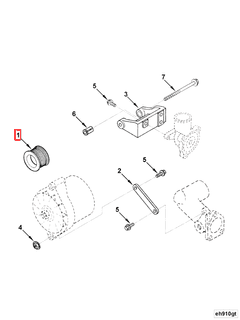

Integration with Alternator

In systems where the alternator is a key component, the Plain Hose Coupling Connector facilitates the connection between the alternator and its associated fluid lines. This ensures that the alternator receives the necessary fluids for cooling and lubrication, which are vital for its efficient operation and longevity. The connector’s design allows for easy attachment and detachment, simplifying maintenance procedures and reducing downtime.

Mounting Considerations

When it comes to mounting, the Plain Hose Coupling Connector plays a significant role in securing fluid lines to the alternator and other engine components. Its robust construction ensures that the connections remain stable under varying engine conditions, including vibrations and temperature fluctuations. This stability is essential for maintaining consistent fluid flow, which is critical for the optimal performance of the alternator and other connected systems.

Overall System Efficiency

By providing a reliable connection point, the Plain Hose Coupling Connector contributes to the overall efficiency of the engine system. It allows for quick and secure connections, which is particularly beneficial during routine maintenance or emergency repairs. The connector’s design also helps in minimizing fluid leaks, thereby ensuring that the engine operates within specified parameters and reducing the risk of damage due to fluid loss.

Conclusion

The 3281534 Plain Hose Coupling Connector is a vital component in maintaining the integrity and efficiency of fluid connections within engine systems, particularly in relation to the alternator and its mounting arrangements. Its robust design, ease of installation, and compatibility with various Cummins engines make it an essential part for ensuring the reliable operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.