This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3627474 Alternator Brace is a component designed to enhance the operation of commercial trucks by providing additional support to the alternator. This part plays a role in maintaining the stability and efficiency of the truck’s electrical system, ensuring reliable performance under various operating conditions 1.

Basic Concepts of Alternator Braces

An alternator brace is a structural component that supports the alternator within a truck’s electrical system. Its primary function is to provide additional stability to the alternator, reducing vibrations and ensuring consistent electrical output. The brace interfaces with the alternator and other components such as the engine and mounting brackets, contributing to the overall integrity of the electrical system 2.

Purpose of the Cummins 3627474 Alternator Brace

The Cummins 3627474 Alternator Brace is designed to support the alternator, playing a role in maintaining its alignment and reducing mechanical stress. By providing a stable mounting point, this Cummins part helps in ensuring that the alternator operates efficiently, which is vital for the consistent performance of the truck’s electrical system. It also aids in minimizing wear and tear on the alternator and its associated components 3.

Key Features

The Cummins 3627474 Alternator Brace is constructed using durable materials, typically including high-strength steel, to ensure longevity and reliability. It features precise mounting points that align with the alternator and engine components, facilitating easy installation and secure attachment. Unique characteristics may include reinforced sections to handle high stress areas and a design that allows for optimal heat dissipation 4.

Benefits of Using the Cummins 3627474 Alternator Brace

Utilizing the Cummins 3627474 Alternator Brace offers several advantages. It enhances the durability of the alternator by providing additional support, which can lead to a longer service life. Improved alternator stability ensures consistent electrical output, which is crucial for the reliable operation of the truck’s electrical system. Additionally, the brace may contribute to increased efficiency by reducing vibrations that can otherwise affect alternator performance 5.

Installation Considerations

When installing the Cummins 3627474 Alternator Brace, it is important to follow guidelines and best practices to ensure proper fitment and function. Preparatory steps include ensuring the alternator and mounting points are clean and free of debris. Required tools may include wrenches, sockets, and possibly a torque wrench to secure the brace properly. Common pitfalls to avoid include over-tightening, which can damage threads, and improper alignment, which can lead to inefficient operation 6.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3627474 Alternator Brace involves inspecting it for signs of wear or damage, such as cracks or excessive corrosion. It is also important to ensure that all mounting points remain secure and that there is no excessive play in the alternator’s movement. Troubleshooting common issues may involve checking for proper alignment and ensuring that all connections are tight and free of corrosion 7.

Performance Impact

The Cummins 3627474 Alternator Brace plays a role in the overall performance and reliability of the truck’s electrical system by providing additional support to the alternator. This support helps in maintaining consistent electrical output, which is vital for the operation of various electrical components within the truck. Enhanced stability and reduced vibrations contribute to the longevity and efficiency of the alternator 8.

Cummins Overview

Cummins Inc. is a well-established company with a significant presence in the commercial truck industry. Founded in 1919, Cummins has built a reputation for producing high-quality engine and power generation equipment. The company’s commitment to innovation and reliability has made it a preferred choice for commercial truck manufacturers and operators worldwide 9.

Cummins Alternator Brace 3627474 Compatibility

The Cummins Alternator Brace part number 3627474 is designed to be compatible with a range of Cummins engines. This part is crucial for securing the alternator in place, ensuring it operates efficiently and reliably. Below is a detailed overview of the engines with which this alternator brace is compatible:

K38 and K50 Engines

The K38 and K50 engines are part of Cummins’ K Series line, known for their robust performance and reliability in various industrial applications. The alternator brace 3627474 fits seamlessly with these engines, providing the necessary support to maintain alternator alignment and reduce vibration.

KTA38GC CM558 and QSK50 CM2150 K107

These engines, KTA38GC CM558 and QSK50 CM2150 K107, are part of Cummins’ QSK Series, which is designed for high-power applications. The alternator brace 3627474 is engineered to fit these engines, ensuring that the alternator remains securely mounted under varying operational conditions.

QSK50 CM2150 MCRS

The QSK50 CM2150 MCRS engine is another variant within the QSK Series, tailored for specific industrial needs. The alternator brace 3627474 is compatible with this engine, providing the essential support required to keep the alternator in optimal position and functioning correctly.

This compatibility ensures that operators can confidently use the Cummins Alternator Brace part number 3627474 across multiple engine models, knowing it will provide the necessary support and stability for the alternator 10.

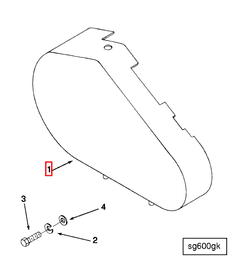

Role of Part 3627474 Alternator Brace in Engine Systems

Part 3627474, the Alternator Brace, is an essential component that enhances the stability and performance of the alternator within various engine systems. By securely connecting the alternator to its mounting points, this brace ensures that the alternator remains firmly in place, minimizing vibrations and maintaining optimal alignment.

The alternator brace works in conjunction with the alternator mounting system to distribute the forces generated during engine operation. This helps to prevent excessive movement of the alternator, which could lead to wear on the mounting points and potential damage to the alternator itself.

Additionally, the brace contributes to the overall structural integrity of the engine compartment. It supports the alternator guard, which protects the alternator from debris and environmental factors, ensuring that the alternator operates efficiently and reliably.

In summary, the alternator brace plays a significant role in maintaining the stability and efficiency of the alternator within the engine system, contributing to the smooth operation of the vehicle 11.

Conclusion

The Cummins 3627474 Alternator Brace is a vital component for enhancing the stability and efficiency of the alternator in commercial trucks. By providing additional support, this part ensures consistent electrical output and reduces mechanical stress on the alternator and its associated components. Proper installation, regular maintenance, and understanding its role in the engine system are crucial for maximizing the benefits of this Cummins part.

-

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411276.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411276.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.