3683004

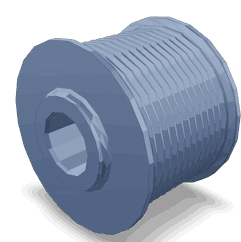

Alternator Pulley

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Alternator Pulley 3683004 by Cummins is a component designed to facilitate the operation of commercial trucks. This pulley is integral to the truck’s electrical system, ensuring the alternator functions correctly. Cummins, a well-established manufacturer in the industry, produces this pulley, leveraging its expertise in diesel engines and related components.

Basic Concepts of Alternator Pulleys

An alternator pulley is a mechanical part that connects the alternator to the engine’s crankshaft via a serpentine belt. Its function is to transfer rotational force from the engine to the alternator, enabling the alternator to generate electricity. This electricity is vital for powering the truck’s electrical systems and recharging the battery. The pulley’s design allows it to maintain the necessary tension on the serpentine belt, ensuring efficient power transmission 1.

Role of the Alternator Pulley in Truck Operation

The Alternator Pulley 3683004 plays a significant role in the electrical system of a truck. By connecting the alternator to the engine, it ensures that the alternator spins at the correct speed to generate the required electrical power. This power is essential for operating the truck’s electrical components, such as lights, radio, and other systems, as well as recharging the battery. The pulley’s precise engineering ensures that the alternator operates within its optimal range, contributing to the overall efficiency and reliability of the truck’s electrical system 2.

Key Features of the Alternator Pulley 3683004

The Alternator Pulley 3683004 is characterized by its robust design and high-quality construction. It is made from durable materials that can withstand the demanding conditions of commercial truck operation. The pulley features a precision-machined surface to ensure smooth belt operation and minimal wear. Its design includes provisions for easy installation and maintenance, enhancing its practicality for fleet operations. Additionally, the pulley is engineered to provide consistent performance over an extended period, reducing the need for frequent replacements 3.

Benefits of Using the Alternator Pulley 3683004

Utilizing the Alternator Pulley 3683004 offers several advantages. Its high-quality construction contributes to improved efficiency in the electrical system, ensuring that the alternator operates optimally. The durability of the pulley means it can withstand the rigors of commercial use, leading to longer service intervals and reduced maintenance costs. Furthermore, the reliable performance of the pulley enhances the overall reliability of the truck’s electrical system, contributing to safer and more efficient operations 4.

Troubleshooting and Maintenance

Common issues with the Alternator Pulley 3683004 may include belt slippage, pulley misalignment, or wear and tear. Regular inspection of the pulley and serpentine belt can help identify potential problems early. Ensuring proper belt tension and alignment is crucial for the pulley’s optimal performance. Maintenance practices should include checking for signs of wear, such as grooves or cracks on the pulley surface, and replacing the belt according to the manufacturer’s recommendations. Addressing these issues promptly can prevent more significant problems and ensure the longevity and optimal performance of the electrical system.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial vehicle industry. The company’s expertise in manufacturing diesel engines and related components, including alternator pulleys, is underpinned by a commitment to innovation, quality, and customer satisfaction. Cummins’ reputation for producing reliable and durable parts makes it a preferred choice for commercial truck operators worldwide.

Compatibility of Alternator Pulley Part 3683004 with Cummins Engines

The Alternator Pulley part number 3683004, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral to the engine’s charging system, ensuring that the alternator operates efficiently to charge the battery and power the vehicle’s electrical systems.

ISX Series Engines

The ISX series engines, including the ISX CM570, ISX CM870, and ISX CM871, are part of Cummins’ lineup of heavy-duty diesel engines. The Alternator Pulley part 3683004 is compatible with these engines, ensuring a secure fit and reliable performance. These engines are known for their robust design and high power output, making them suitable for various heavy-duty applications.

ISX15 Series Engines

The ISX15 series engines, such as the ISX15 CM2250, ISX15 CM2250 SN, and ISX15 CM2350 X101, are part of the next generation of Cummins’ heavy-duty diesel engines. The Alternator Pulley part 3683004 is engineered to fit these engines seamlessly. These engines are designed to deliver exceptional performance and efficiency, making them ideal for demanding applications.

X15 Series Engines

The X15 series engines, including the X15 CM2350 X116B, X15 CM2350 X123B, and X15 CM2450 X134B, are another part of Cummins’ extensive range of heavy-duty diesel engines. The Alternator Pulley part 3683004 is compatible with these engines, ensuring a precise fit and reliable operation. These engines are engineered to provide outstanding power and efficiency, suitable for a wide range of heavy-duty applications.

By ensuring that the Alternator Pulley part 3683004 fits these various Cummins engines, it guarantees that the alternator can function correctly, maintaining the electrical systems’ integrity and performance across different engine models.

Role of Part 3683004 Alternator Pulley in Engine Systems

The Part 3683004 Alternator Pulley is an essential component in the efficient operation of engine systems. It is specifically designed to interface with the alternator, ensuring that the alternator operates within the optimal speed range to generate the necessary electrical power for the vehicle’s electrical systems.

Integration with the Alternator

The Alternator Pulley is mounted on the alternator’s shaft. This pulley engages with the serpentine belt, which is driven by the engine’s crankshaft. As the engine runs, the crankshaft’s rotation is transferred to the serpentine belt, which in turn rotates the Alternator Pulley. This rotational motion is then transmitted to the alternator, allowing it to generate electricity.

Function in the Engine System

In the engine system, the Alternator Pulley plays a significant role in maintaining the balance between mechanical and electrical energy. By ensuring the alternator spins at the correct speed, the pulley helps in charging the battery and powering the vehicle’s electrical components, such as lights, ignition systems, and various sensors.

Interaction with the Mounting System

The mounting of the alternator is also influenced by the presence of the Alternator Pulley. Proper alignment and secure mounting are essential to prevent any slippage or misalignment of the serpentine belt. This ensures that the pulley can perform its function without causing undue wear or damage to the alternator or other components in the engine system.

Conclusion

The Alternator Pulley 3683004 by Cummins is a critical component in the operation of commercial trucks, ensuring the alternator functions correctly and efficiently. Its robust design, high-quality construction, and compatibility with various Cummins engines make it a reliable choice for fleet operations. Regular maintenance and proper installation are essential to ensure the longevity and optimal performance of this Cummins part.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.