This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

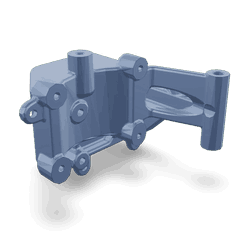

The Alternator Support (part 3697329) is a critical component designed to enhance the operation of commercial trucks by providing structural support to the alternator. This part ensures the alternator remains securely in place, which is essential for the consistent generation of electrical power needed for various truck systems. Cummins, a renowned manufacturer in the commercial truck industry, produces this alternator support. Known for its commitment to quality and innovation, Cummins plays a significant role in enhancing the reliability and performance of truck components.

Function and Operation

The Alternator Support (part 3697329) functions by securing the alternator within the truck’s electrical system. It plays a role in maintaining the alternator’s position, which is vital for its efficient operation. By keeping the alternator stable, this support helps ensure a steady electrical output, which is necessary for powering the truck’s electrical systems, including lights, instruments, and other electronic components. The secure mounting provided by the alternator support also helps in reducing vibrations that could otherwise affect the alternator’s performance 1.

Key Features

The Alternator Support (part 3697329) is constructed from durable materials, designed to withstand the rigors of commercial truck operations. Its design includes features such as precise mounting points and robust brackets, which contribute to its stability and longevity. Additionally, the support is engineered to accommodate various alternator sizes and types, making it a versatile component for different truck models. The material composition and design elements of this part are tailored to enhance its performance and reliability in demanding environments 2.

Benefits

The use of the Alternator Support (part 3697329) offers several benefits. Its durable construction contributes to improved longevity, ensuring that the alternator remains securely in place over extended periods. This stability enhances the reliability of the truck’s electrical system, leading to consistent performance. Furthermore, by maintaining the alternator’s position, this support can contribute to overall truck performance by ensuring that the electrical systems operate efficiently 3.

Installation Process

Installing the Alternator Support (part 3697329) involves several steps to ensure proper placement and functionality. Begin by disconnecting the battery to prevent any electrical issues during installation. Next, remove the old alternator support if present, taking care to note the positioning for reference. Align the new support with the mounting points on the truck’s engine compartment. Secure it in place using the provided fasteners, ensuring that all connections are tight and stable. Reconnect the battery and test the alternator’s operation to confirm that the support is installed correctly.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the Alternator Support (part 3697329), regular maintenance is recommended. Inspect the support for any signs of wear or damage, particularly after extended use or exposure to harsh conditions. Tighten any loose fasteners and replace any worn components as needed. Common issues may include vibrations or electrical inconsistencies, which can often be traced back to the alternator support. Addressing these issues promptly can prevent more significant problems down the line.

Safety Considerations

When installing or maintaining the Alternator Support (part 3697329), it is important to observe several safety guidelines. Always disconnect the battery before beginning any work to avoid electrical shocks. Use the appropriate tools and follow the manufacturer’s instructions to ensure a secure and correct installation. Additionally, be mindful of the electrical components and wiring in the vicinity to prevent damage. Proper handling procedures should be followed to avoid injuries or component damage.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, with a history of innovation and quality. Founded in 1919, Cummins has grown to become a global leader in the production of diesel engines and related technologies. The company is known for its commitment to developing reliable and efficient components that enhance the performance and durability of commercial trucks. Cummins’ dedication to quality is evident in its rigorous testing and manufacturing processes, ensuring that each component, including the Alternator Support (part 3697329), meets high standards of performance and reliability 4.

Compatibility

The Alternator Support (part 3697329) is designed to be compatible with a range of engine models. This support component is integral for maintaining the proper alignment and function of the alternator within the engine system.

ISG12 CM2880 G107

The ISG12 CM2880 G107 engine benefits from the precise fit and robust construction of the Alternator Support (part 3697329). This part ensures that the alternator operates smoothly and efficiently, contributing to the overall performance and longevity of the engine.

QSG12/X12 CM2350 G110

Similarly, the QSG12/X12 CM2350 G110 engine is another model that integrates seamlessly with the Alternator Support (part 3697329). This compatibility is crucial for maintaining the alternator’s position and function, which is vital for the engine’s electrical system and overall operational integrity.

By ensuring a secure fit and reliable performance, the Alternator Support (part 3697329) plays a key role in the maintenance and efficiency of these engine models.

Understanding the Role of Part 3697329 Alternator Support in Engine Systems

The Alternator Support (part 3697329) is a vital component in the integration of the alternator within various engine systems. Its primary function is to provide a secure and stable mounting point for the alternator, ensuring it remains firmly in place during engine operation.

Integration with the Alternator

The alternator support is designed to interface directly with the alternator. It facilitates the proper alignment and positioning of the alternator, which is necessary for efficient power generation. The support ensures that the alternator is held at the correct angle and distance from the engine’s rotating components, such as the crankshaft, allowing the drive belt to operate effectively.

Interaction with the Mounting System

In conjunction with the engine’s mounting system, the alternator support plays a significant role in maintaining the structural integrity of the alternator. It is typically bolted to the engine block or other sturdy components, providing a robust foundation that can withstand the vibrations and stresses generated during engine operation. This secure mounting is vital for the longevity and reliability of the alternator.

Ensuring Stability and Performance

By offering a stable platform for the alternator, the support contributes to the overall performance and efficiency of the engine system. It helps in reducing undue strain on the alternator and its associated components, such as the drive belt and pulleys. This stability is particularly important in high-performance or high-stress applications where engine vibrations can be more pronounced.

Facilitating Maintenance and Repairs

The alternator support also aids in the ease of maintenance and repairs. Its design allows for straightforward access to the alternator, making it simpler to perform inspections, replacements, or adjustments. This accessibility is beneficial for both routine maintenance and unexpected repairs, contributing to the overall efficiency of engine management.

Conclusion

The Alternator Support (part 3697329) is a crucial component in the operation and maintenance of commercial truck engines. Its durable construction, precise design, and compatibility with various engine models make it an essential part for ensuring the reliable and efficient performance of the alternator. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall performance and longevity of the truck’s electrical system.

-

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩ -

Giles, Tim. Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning, 2019.

↩ -

Schuetz, Thomas. Aerodynamics of Road Vehicles: Fifth Edition. SAE International, 2016.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5504630, QSK60 CM2350 K136.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.