Understanding The Cummins 3919398 Alternator Pulley: A Comprehensive Guide

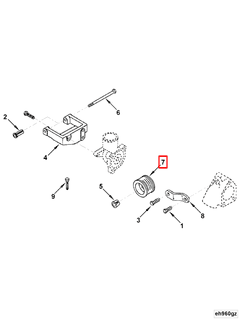

Introduction To The Cummins 3919398 Alternator Pulley

The Cummins 3919398 alternator pulley is a critical component in the engine systems of commercial trucks. This part ensures the alternator operates efficiently, which in turn maintains the electrical system of the vehicle. Understanding its function, importance, and maintenance can significantly enhance the performance and longevity of a truck’s engine 1.

Basic Concepts Of An Alternator Pulley

An alternator pulley is a mechanical device that connects the alternator to the engine’s accessory belt. Its primary function is to transfer rotational energy from the engine to the alternator, which converts this mechanical energy into electrical energy. This process is essential for charging the vehicle’s battery and powering the electrical systems while the engine is running 2.

How An Alternator Pulley Works

The alternator pulley works in conjunction with the engine’s accessory belt. As the engine runs, it spins the crankshaft, which in turn rotates the accessory belt. The alternator pulley is attached to the alternator and is gripped by the accessory belt. This setup allows the alternator to spin at the same speed as the engine, ensuring it generates the correct amount of electrical power 3.

Purpose Of The Cummins 3919398 Alternator Pulley

The Cummins 3919398 alternator pulley plays a vital role in the operation of a truck. It ensures that the alternator functions correctly, which is crucial for maintaining the electrical systems of the vehicle. Without a properly functioning alternator pulley, the alternator may not spin at the correct speed, leading to insufficient charging of the battery and potential electrical failures.

Importance Of The Cummins 3919398 Alternator Pulley In Truck Operations

In commercial trucks, reliable electrical systems are paramount. The Cummins 3919398 alternator pulley helps maintain these systems by ensuring the alternator operates efficiently. This is especially important for trucks that rely heavily on electrical systems for navigation, communication, and other critical functions.

Troubleshooting The Cummins 3919398 Alternator Pulley

Regular maintenance and timely troubleshooting can prevent issues with the Cummins 3919398 alternator pulley. Common problems include wear and tear, misalignment, and damage to the accessory belt. If the alternator pulley is not functioning correctly, it may cause the alternator to spin too slowly or too quickly, leading to electrical issues.

Maintenance Tips For The Cummins 3919398 Alternator Pulley

To ensure the longevity and efficiency of the Cummins 3919398 alternator pulley, regular maintenance is essential. This includes inspecting the accessory belt for signs of wear, checking the alignment of the pulley, and ensuring that the alternator is securely attached. Lubricating the pulley can also help reduce friction and wear.

Cummins Alternator Pulley 3919398 Compatibility

The Cummins Alternator Pulley part number 3919398 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This part is engineered to meet the specific needs of the engines it is intended for, providing a critical function in the power generation and distribution system.

Engine Compatibility

- 4B3.9 and 6B5.9 Engines

The 3919398 Alternator Pulley is compatible with both the 4B3.9 and 6B5.9 engines. These engines are known for their robust design and efficiency, making the alternator pulley an essential component in maintaining their operational integrity. The pulley ensures that the alternator operates at the correct speed, which is vital for generating the necessary electrical power to support the engine’s various systems.

- B5.9 G Engine

The B5.9 G engine also benefits from the use of the 3919398 Alternator Pulley. This engine variant is part of a series that is recognized for its durability and performance in demanding applications. The alternator pulley’s precise fit and function are crucial for the B5.9 G engine, as it directly influences the alternator’s ability to charge the battery and power the electrical systems while the engine is running.

Key Considerations

When installing the 3919398 Alternator Pulley in any of these engines, it is important to ensure that the pulley is correctly aligned and securely fastened. Proper installation is key to preventing issues such as belt slippage or premature wear, which can lead to reduced efficiency and potential engine damage. Cummins has designed this pulley to work in harmony with the specified engines, ensuring that it meets the high standards of performance and reliability expected by users.

Role of Part 3919398 Alternator Pulley in Engine Systems

The alternator pulley, specifically part 3919398, is an integral component in the efficient operation of an engine’s electrical system. It is designed to work in conjunction with the alternator and the engine’s accessory drive system.

When the engine is running, the alternator pulley is driven by the engine’s serpentine belt. This pulley is mounted on the alternator, allowing it to rotate at a speed proportional to the engine’s RPM. As the pulley turns, it drives the alternator, which generates electrical power to charge the battery and power the vehicle’s electrical systems.

The alternator pulley’s design ensures a precise fit and smooth operation, minimizing wear and reducing the risk of belt slippage. This is essential for maintaining consistent alternator output and preventing damage to the belt or other components.

Conclusion

The Cummins 3919398 alternator pulley is a critical component in the engine systems of commercial trucks. Understanding its function, importance, and maintenance can help ensure the reliable operation of a truck’s electrical systems. By following proper maintenance practices and being aware of potential issues, engineers, mechanics, and fleet operators can keep their trucks running smoothly and efficiently.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.