This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Injector Plunger Link 3957605, a component manufactured by Cummins, is integral to the operation of heavy-duty trucks. This Cummins part is designed to meet the demanding requirements of diesel engines used in heavy-duty applications, playing a significant role in the fuel injection system 1.

Basic Concepts and Functionality

This part operates on fundamental principles of mechanical engineering to facilitate precise fuel delivery in a diesel engine. It connects the injector plunger to the camshaft, translating the camshaft’s motion into the precise movement of the injector plunger. This process is vital for the atomization of fuel, which in turn affects combustion efficiency and engine performance 2.

Purpose of the Injector Plunger Link

The Injector Plunger Link 3957605 ensures that the injector plunger moves in sync with the engine’s operation, allowing for the accurate timing and quantity of fuel injection. This precise control over fuel delivery contributes to efficient combustion, which is crucial for the engine’s performance and fuel efficiency. Additionally, it helps in maintaining the engine’s power output and reducing emissions 3.

Key Features

This Cummins part is characterized by its robust design and the use of high-quality materials, ensuring durability and reliability under the demanding conditions of heavy-duty truck operation. Its design includes features that enhance its functionality, such as precise machining for accurate movement and materials that resist wear and corrosion.

Benefits

The use of the Injector Plunger Link 3957605 offers several advantages, including improved fuel efficiency, enhanced engine performance, and increased reliability. By ensuring precise fuel delivery, it contributes to more efficient combustion, which can lead to better fuel economy. Additionally, its role in maintaining engine performance helps in achieving consistent power output and reducing the likelihood of engine-related issues.

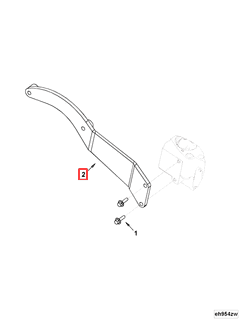

Installation Process

Installing the Injector Plunger Link 3957605 requires careful attention to detail to ensure proper fitting and operation. The process involves several steps, including the preparation of the engine compartment, the alignment of the link with the camshaft and injector plunger, and the securing of the link in place. It is important to use the correct tools and follow manufacturer guidelines to avoid damage to the component or the engine.

Common Issues and Troubleshooting

Typical problems associated with the Injector Plunger Link may include wear, misalignment, or damage due to engine vibrations. Symptoms of a faulty link can manifest as poor engine performance, irregular fuel injection, or increased emissions. Troubleshooting involves inspecting the link for signs of wear or damage, ensuring proper alignment, and replacing the component if necessary.

Maintenance Tips

Regular maintenance of the Injector Plunger Link is crucial for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning to remove any debris that may affect its operation, and replacement according to the manufacturer’s recommendations or based on the condition of the component. Adhering to these maintenance practices can help in preventing unexpected failures and ensuring the engine operates efficiently.

Compatibility and Applications

The Injector Plunger Link 3957605 is designed for use in specific Cummins engine series, commonly found in various heavy-duty truck models. Its compatibility ensures that it meets the performance and durability requirements of these engines, contributing to their efficient operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation for quality and innovation in the automotive industry, Cummins is committed to advancing diesel engine technology, ensuring that their products meet the high standards expected in heavy-duty applications.

Compatibility of Injector Plunger Link Part 3957605 with Cummins Engines

The Injector Plunger Link part number 3957605, manufactured by Cummins, is designed to fit a range of Cummins engines. This part is integral to the operation of the fuel injection system, ensuring that the injector plunger operates smoothly and efficiently.

ISB CM2150, ISB CM550, and ISB CM850

The Injector Plunger Link part 3957605 is compatible with the ISB CM2150, ISB CM550, and ISB CM850 engines. These engines are part of Cummins’ ISB series, known for their reliability and performance in various applications. The part ensures that the injector plunger maintains the correct position and movement, which is crucial for maintaining optimal fuel injection timing and pressure.

ISB6.7 CM2250 and ISB6.7 CM2350 B101

Similarly, the Injector Plunger Link part 3957605 fits the ISB6.7 CM2250 and ISB6.7 CM2350 B101 engines. These engines are part of the ISB6.7 series, which is designed for heavy-duty applications. The part’s compatibility with these engines ensures that the injector plunger functions correctly, contributing to the engine’s overall efficiency and performance.

Understanding the Role of Part 3957605 Injector Plunger Link in Engine Systems

The 3957605 Injector Plunger Link is an integral component within the fuel injection system of various engine setups. Its primary function is to facilitate the precise movement of the injector plunger, ensuring that fuel is delivered to the combustion chamber at the exact moment required for optimal engine performance.

Integration with Key Engine Components

Fuel Injection System

Within the fuel injection system, the 3957605 Injector Plunger Link works in conjunction with the injector pump and the injector nozzles. It translates the mechanical motion from the camshaft into the necessary action on the injector plunger, allowing for controlled fuel delivery. This ensures that the fuel is atomized correctly, promoting efficient combustion and reducing emissions.

Camshaft and Valve Train

The Injector Plunger Link is often driven by the camshaft, which is a fundamental part of the valve train. The camshaft’s lobes push on the link, which then actuates the injector plunger. This mechanical linkage ensures that fuel injection is synchronized with the opening of the intake valves, maximizing air-fuel mixture efficiency.

Alternator Mounting and Electrical System

Although the 3957605 Injector Plunger Link is primarily a mechanical component, its operation is indirectly influenced by the engine’s electrical system. The alternator, mounted typically on the engine, provides the necessary electrical power to operate the fuel injection system’s electronic control unit (ECU). The ECU, in turn, monitors and adjusts the fuel injection timing and quantity, ensuring that the Injector Plunger Link performs optimally under varying engine loads and speeds.

Engine Mounting and Structural Integrity

The stability and alignment of the engine mounting play a significant role in the performance of the Injector Plunger Link. Proper engine mounting ensures that the mechanical components, including the camshaft and the Injector Plunger Link, maintain precise alignment. This alignment is essential for the consistent and reliable operation of the fuel injection system, directly impacting engine performance and durability.

Conclusion

In summary, the 3957605 Injector Plunger Link is a key component that interacts with various engine systems to ensure precise fuel delivery. Its role is essential in maintaining the efficiency and performance of the engine, working in harmony with the camshaft, fuel injection system, alternator, and engine mounting.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.