3965147

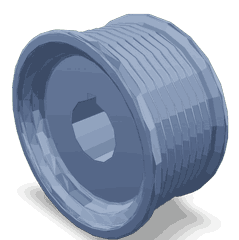

Alternator Pulley

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3965147 Alternator Pulley is a component designed for use in commercial trucks. It plays a role in the operation of these vehicles by facilitating the function of the alternator, which is responsible for generating electrical power. Understanding its purpose and significance can help in maintaining the efficiency and reliability of truck operations.

Basic Concepts of Alternator Pulleys

An alternator pulley is a part of the alternator system that allows the alternator to rotate. This rotation is driven by a belt connected to the engine’s crankshaft. As the engine runs, the pulley spins the alternator, which in turn generates electrical power to charge the vehicle’s battery and power its electrical systems 1.

Purpose of the 3965147 Alternator Pulley

This Cummins part specifically plays a role in ensuring that the alternator operates efficiently within a truck’s engine system. It is designed to interact seamlessly with the alternator and the engine, providing a smooth transfer of rotational force. This interaction is vital for maintaining the alternator’s ability to generate a consistent electrical output, which is important for the truck’s electrical systems.

Key Features

The 3965147 Alternator Pulley is characterized by its robust design and the materials used in its construction. It is typically made from durable materials that can withstand the high stresses and temperatures encountered in a truck’s engine compartment. Its design may include features such as a ribbed surface to grip the belt more effectively, enhancing both performance and durability 2.

Benefits

Using this part can lead to improved efficiency in the alternator’s operation, contributing to the overall reliability of the truck’s electrical system. Its durable construction also means it can offer longevity, reducing the frequency of replacements and maintenance costs over time.

Installation Process

Installing the 3965147 Alternator Pulley involves several steps. First, the old pulley must be removed, which may require loosening the belt tension. Once the old pulley is off, the new pulley can be aligned with the alternator and secured in place. Tools such as wrenches and possibly a belt tensioner tool may be needed. It’s important to ensure that the pulley is properly aligned and that the belt is correctly tensioned to avoid issues with the alternator’s operation.

Troubleshooting Common Issues

Common issues with the 3965147 Alternator Pulley may include squeaking, wobbling, or failure to engage properly. Squeaking can often be addressed by ensuring the belt is correctly tensioned and aligned. Wobbling may indicate a problem with the pulley’s mounting or the alternator itself. Failure to engage could be due to belt wear or misalignment. Regular inspections can help identify these issues early.

Maintenance Tips

To ensure the optimal performance and longevity of the 3965147 Alternator Pulley, regular maintenance is recommended. This includes inspecting the pulley and belt for signs of wear or damage, ensuring proper belt tension, and lubricating moving parts as necessary. Following the manufacturer’s guidelines for replacement can also help maintain the efficiency of the alternator system 3.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of diesel engines and related technologies. With a history of innovation and quality, Cummins products are designed to meet the demanding requirements of commercial applications, providing reliability and performance across various industries.

Compatibility of Alternator Pulley Part 3965147 with Cummins Engines

The Cummins Alternator Pulley part number 3965147 is designed to fit a variety of Cummins engines, ensuring reliable power generation and efficient alternator operation. Here is a detailed overview of its compatibility with different engine models:

ISB and ISB/ISD Engines

- ISB CM2150

- ISB/ISD4.5 CM2150 B119

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

These engines, part of the ISB and ISB/ISD series, are known for their robust performance and fuel efficiency. The alternator pulley part 3965147 is engineered to work seamlessly with these models, ensuring consistent alternator operation and power generation.

ISC Engines

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

The ISC series engines are designed for heavy-duty applications, and the alternator pulley part 3965147 is compatible with these models. This ensures that the alternator can operate efficiently, providing the necessary power for the vehicle’s electrical systems.

ISL Engines

- ISL CM2150

- ISL CM554

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

The ISL series engines are known for their durability and performance in various applications. The alternator pulley part 3965147 is designed to fit these engines, ensuring that the alternator can function optimally under different operating conditions.

Other Cummins Engines

- 6C8.3

- C GAS PLUS CM556

- C8.3 G

- G5.9

- G5.9 CM558

- G8.3

- G8.3 CM558

- GTA8.3 CM558

- L GAS PLUS CM556

- L8.9

- L8.9 L121

These engines, while not as commonly referenced as the ISB, ISC, and ISL series, are still integral to various applications. The alternator pulley part 3965147 is compatible with these models, ensuring that the alternator can operate efficiently across a wide range of engine types.

By ensuring compatibility with these various engine models, the Cummins Alternator Pulley part 3965147 provides a reliable solution for maintaining alternator performance and power generation across different engine types.

Role of Part 3965147 Alternator Pulley in Engine Systems

The alternator pulley, identified by part number 3965147, is an integral component in the efficient operation of an engine’s electrical system. This pulley is designed to facilitate the transfer of mechanical energy from the engine to the alternator, ensuring that the alternator can generate the necessary electrical power to charge the battery and power the vehicle’s electrical systems.

Interaction with the Alternator

The alternator pulley is mounted on the alternator’s drive shaft. As the engine runs, the pulley engages with the alternator drive belt, transferring rotational force from the engine to the alternator. This mechanical connection is essential for the alternator to spin at the correct speed, allowing it to convert mechanical energy into electrical energy efficiently.

Connection to the Alternator Drive

The alternator drive system relies on the pulley to maintain the proper tension and alignment of the drive belt. The pulley’s design ensures that the belt remains in optimal contact with both the pulley and the crankshaft pulley, minimizing slippage and maximizing the transfer of power. This consistent drive is necessary for the alternator to operate within its specified parameters, ensuring reliable electrical output.

Importance in Alternator Mounting

Proper mounting of the alternator is facilitated by the alternator pulley. The pulley’s position and alignment are critical for the alternator to be securely held in place within the engine compartment. This secure mounting prevents excessive movement or vibration, which could lead to inefficiencies or damage to the alternator or its connections.

Overall System Integration

In summary, the alternator pulley (part 3965147) plays a significant role in the integration and function of the alternator within the engine system. It ensures that the alternator receives the necessary mechanical input to generate electricity, maintains the integrity of the drive belt system, and contributes to the stable mounting of the alternator. Each of these functions is important for the overall performance and reliability of the vehicle’s electrical system.

Conclusion

The Cummins 3965147 Alternator Pulley is a critical component in the efficient operation of commercial truck engines. Its robust design, compatibility with various Cummins engines, and role in the alternator system make it an essential part for maintaining the reliability and performance of truck electrical systems. Regular maintenance and proper installation are key to ensuring the longevity and efficiency of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.