This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

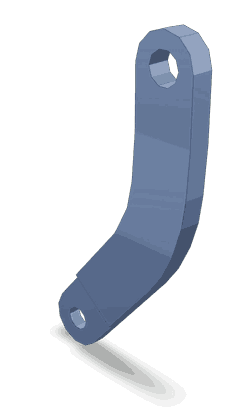

The 3971982 Alternator Bracket, manufactured by Cummins, is a significant component within the realm of truck components, particularly for its role in the electrical system of commercial trucks.

Basic Concepts of Alternator Brackets

An alternator bracket serves as a mounting point for the alternator within a truck’s electrical system. It secures the alternator to the engine, allowing it to spin and generate electricity. This bracket interfaces with both the alternator and the engine, ensuring that the alternator remains in the correct position and operates efficiently 1.

Purpose of the 3971982 Alternator Bracket

This Cummins part plays a role in the operation of a truck by securing the alternator in place. This ensures that the alternator can efficiently convert mechanical energy from the engine into electrical energy, which is then used to power the truck’s electrical systems and recharge the battery 2.

Key Features

This part is designed with specific characteristics that enhance its durability and functionality. It is constructed from high-quality materials that can withstand the rigors of commercial truck use. Its design ensures a secure fit for the alternator, contributing to the overall efficiency and reliability of the truck’s electrical system.

Benefits

The 3971982 Alternator Bracket offers several advantages. It contributes to the improved reliability of the electrical system by securely holding the alternator in place. Its design also facilitates ease of installation, and it is compatible with specific truck models, ensuring a proper fit and function.

Installation Process

Installing this part involves several steps. First, the alternator is positioned in its designated location. The bracket is then aligned with the mounting points on the engine. Using the appropriate tools, the bracket is secured in place, ensuring that the alternator is held firmly and operates within the correct parameters.

Troubleshooting Common Issues

Common problems associated with alternator brackets include loose connections or signs of wear and tear. Regular inspections can help identify these issues early. Solutions may involve tightening connections or, in cases of significant wear, replacing the bracket to maintain the efficiency of the electrical system.

Maintenance Tips

To ensure the longevity and optimal performance of this Cummins part, regular maintenance checks are recommended. This includes inspecting the bracket for signs of wear, ensuring that all connections are secure, and verifying that the alternator is operating within the manufacturer’s specifications. Adhering to these practices can help prevent issues and ensure the reliable operation of the truck’s electrical system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. Their product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles 3.

Cummins Alternator Bracket 3971982 Compatibility

The Cummins Alternator Bracket 3971982 is designed to fit seamlessly with the QSB5.9 CM850 and QSB6.7 M CM2250 engines. This bracket is a critical component in the engine’s electrical system, ensuring the alternator is securely mounted and properly aligned.

For the QSB5.9 CM850 engine, the bracket’s design ensures it fits the specific mounting points and engine layout of this model. The precision engineering of the bracket allows for efficient power generation and distribution, maintaining the engine’s performance and reliability.

Similarly, the QSB6.7 M CM2250 engine benefits from the 3971982 bracket. Its design accommodates the larger engine’s dimensions and power output, providing a robust mounting solution that supports the alternator’s function. This compatibility ensures that the alternator operates effectively, contributing to the engine’s overall efficiency and longevity.

Both engines rely on this alternator bracket to maintain the integrity of their electrical systems. The bracket’s compatibility with these models underscores Cummins’ commitment to providing high-quality, reliable parts that enhance engine performance and durability.

Role of Part 3971982 Alternator Bracket in Engine Systems

The 3971982 Alternator Bracket is an essential component in the integration and operation of the alternator within various engine systems. This bracket serves as a secure mounting point for the alternator, ensuring it is properly aligned and held in place during engine operation.

When installed, the Alternator Bracket interfaces directly with the engine block or other structural components, providing a stable foundation for the alternator. This stability is important for the alternator’s performance, as it allows for consistent operation of the alternator’s pulley and drive belt.

The bracket also facilitates the connection of electrical cables from the alternator to the battery and other electrical components, ensuring efficient power distribution throughout the engine system. Additionally, the Alternator Bracket often includes provisions for attaching ancillary components such as voltage regulators or additional wiring harnesses, further enhancing the alternator’s functionality within the engine system.

Overall, the proper installation and maintenance of the Alternator Bracket are important for the reliable operation of the alternator and the overall efficiency of the engine system.

Conclusion

The 3971982 Alternator Bracket is a vital component in the electrical system of commercial trucks, ensuring the alternator is securely mounted and operates efficiently. Its design and compatibility with specific engine models contribute to the reliability and performance of the truck’s electrical system. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.