This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

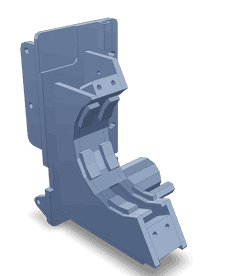

The Cummins 4001232 Alternator Bracket is a component designed to support the alternator in commercial trucks. Its role is to secure the alternator in place, ensuring it operates efficiently within the truck’s electrical system. This bracket is integral to maintaining the alternator’s alignment and stability, which is vital for the consistent performance of the truck’s electrical components 1.

Purpose and Functionality

The primary purpose of the 4001232 Alternator Bracket is to provide a stable mounting point for the alternator. By securing the alternator, the bracket helps maintain its position relative to the engine, which is crucial for the alternator’s ability to generate electricity efficiently. This support is fundamental to the alternator’s function, as it ensures that the alternator can spin at the correct speed and angle, thereby contributing to the overall electrical system’s reliability and performance 2.

Key Features

The 4001232 Alternator Bracket is characterized by its robust design and the materials used in its construction. Typically made from high-strength steel, this bracket is engineered to withstand the vibrations and stresses associated with heavy-duty truck operations. Its design includes precise mounting points and secure attachment mechanisms, which are tailored to fit specific alternator models, ensuring a snug and durable fit 3.

Benefits

Utilizing the 4001232 Alternator Bracket offers several advantages. Its sturdy construction enhances the reliability of the alternator’s mounting, reducing the risk of alternator displacement or failure. This reliability contributes to the overall durability of the truck’s electrical system, ensuring consistent performance over time. Additionally, the efficient support provided by the bracket helps maintain optimal alternator operation, which is crucial for the truck’s electrical system’s longevity 4.

Installation Process

Installing the 4001232 Alternator Bracket involves several steps to ensure a secure and correct fit. The process begins with the removal of the old bracket, if present, followed by the alignment of the new bracket with the mounting points on the truck’s engine. Specific tools, such as wrenches and possibly a torque wrench, may be required to tighten the bracket securely in place. It is important to follow the manufacturer’s guidelines for torque specifications to avoid over-tightening, which could damage the bracket or the alternator.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the 4001232 Alternator Bracket, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, such as cracks or loose bolts. Common issues that may arise include bracket misalignment or damage from road debris. Troubleshooting steps may involve realigning the bracket or replacing damaged components. Regular checks can help identify potential problems early, ensuring the alternator remains securely mounted and operates efficiently.

Compatibility and Applications

The 4001232 Alternator Bracket is designed for use in specific commercial trucks and engines, offering compatibility with various alternator models. Its design allows for versatile application across different truck makes and models, making it a valuable component for fleet managers and maintenance professionals looking to ensure their vehicles’ electrical systems are reliable and efficient.

Manufacturer - Cummins

Cummins Inc. is a leading manufacturer in the diesel engine and related component industry, known for its commitment to quality and innovation. With a rich history of providing reliable and high-performance products, Cummins has established a strong reputation in the automotive and heavy-duty truck sectors. The company’s dedication to excellence is evident in its wide range of components, including the 4001232 Alternator Bracket, which is designed to meet the demanding requirements of commercial truck applications.

Cummins Alternator Bracket 4001232 Compatibility

The Cummins Alternator Bracket part number 4001232 is designed to fit a range of Cummins engines, ensuring a secure and reliable connection for the alternator. This bracket is integral for maintaining the alternator’s position and function, which is crucial for the engine’s electrical system.

QSK45 CM500 and QSK60 CM500

The QSK45 CM500 and QSK60 CM500 engines are part of Cummins’ QSK series, known for their robust performance and reliability. The 4001232 alternator bracket is engineered to fit these engines, providing a precise mounting solution that ensures the alternator operates efficiently. This compatibility is essential for maintaining the electrical output necessary for the engine’s operation.

QSK60 CM850 MCRS and QSK78 CM500

The QSK60 CM850 MCRS and QSK78 CM500 engines represent a higher power output within the QSK series, designed for demanding applications. The 4001232 alternator bracket is also compatible with these engines, ensuring that the alternator is securely mounted and aligned. This is particularly important for these higher power engines, where precise electrical management is critical to performance and longevity.

The compatibility of the 4001232 alternator bracket across these engines underscores its versatility and importance in maintaining the integrity of the engine’s electrical system. Whether in the QSK45 CM500, QSK60 CM500, QSK60 CM850 MCRS, or QSK78 CM500, this bracket provides a reliable solution for alternator mounting, ensuring consistent performance and durability.

Role of Part 4001232 Alternator Bracket in Engine Systems

The 4001232 Alternator Bracket is an essential component in the integration of the alternator within various engine systems. This bracket facilitates the secure mounting of the alternator to the engine, ensuring stability and proper alignment during operation.

When installed, the Alternator Bracket interfaces directly with the engine block or other structural components, providing a robust foundation for the alternator. This setup is vital for maintaining the alternator’s position relative to the crankshaft pulley, which it engages via a belt drive system.

The bracket’s design allows for precise adjustment, enabling the tension of the drive belt to be correctly set. This is important for efficient power transmission from the engine to the alternator, which in turn ensures consistent electrical output.

Additionally, the Alternator Bracket plays a role in managing the thermal environment around the alternator. By maintaining a fixed distance from heat-generating components, it helps in dissipating heat effectively, contributing to the longevity and reliability of the alternator.

In summary, the 4001232 Alternator Bracket is integral to the functional integrity of the alternator within the engine system, supporting both mechanical and thermal management aspects.

Conclusion

The Cummins 4001232 Alternator Bracket is a critical component for the reliable operation of alternators in commercial trucks. Its robust design, compatibility with various Cummins engines, and role in maintaining alternator alignment and stability make it an indispensable part of the truck’s electrical system. Regular maintenance and proper installation are key to ensuring the longevity and efficiency of this component.

-

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Parikyan, Tigran Ed. Advances in Engine and Powertrain Research and Technology. Springer Nature, 2022.

↩ -

Barton, David C, and John D Fieldhouse. Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.