This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

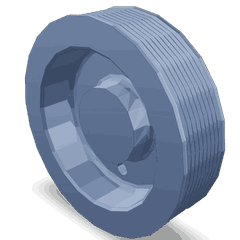

The Cummins Alternator Pulley 4009258 is a component designed for use in commercial trucks. It plays a significant role in the operation of these vehicles by facilitating the efficient generation of electrical power. This pulley is integral to the alternator system, ensuring that the truck’s electrical needs are met reliably and consistently.

Basic Concepts of Alternator Pulleys

An alternator pulley is a mechanical component that connects the alternator to the engine’s crankshaft via a belt. Its function is to transfer rotational energy from the engine to the alternator, enabling the alternator to generate electrical power. This power is used to charge the truck’s battery and to operate electrical systems while the engine is running. The efficiency and reliability of this transfer are crucial for the overall performance of the truck’s electrical system 1.

Purpose of the Cummins Alternator Pulley 4009258

The Cummins Alternator Pulley 4009258 ensures the smooth and efficient transfer of energy from the engine to the alternator. This transfer is vital for maintaining the electrical system’s efficiency and reliability. By optimizing this process, the pulley contributes to the overall performance and longevity of the alternator system.

Key Features

The Cummins Alternator Pulley 4009258 is characterized by its robust design and the use of high-quality materials. These features enhance its performance and durability. The pulley is engineered to withstand the demanding conditions of commercial truck operations, ensuring consistent performance over time. Its design also facilitates easy installation and maintenance, contributing to its overall effectiveness.

Benefits

Using the Cummins Alternator Pulley 4009258 offers several benefits. These include improved efficiency in the transfer of energy to the alternator, enhanced reliability of the electrical system, and increased longevity of the alternator components. These benefits contribute to the overall performance and durability of the truck’s electrical system.

Installation and Compatibility

Proper installation of the Cummins Alternator Pulley 4009258 is crucial for ensuring optimal performance. This involves following specific procedures to ensure that the pulley is correctly aligned and securely fastened. Attention to these details during installation helps to prevent issues such as belt slippage or pulley misalignment, which can affect the efficiency and reliability of the alternator system 2.

Maintenance and Troubleshooting

Regular maintenance of the Cummins Alternator Pulley 4009258 is important for ensuring long-term performance. This includes inspecting the pulley for signs of wear or damage, ensuring that the belt is properly tensioned, and lubricating moving parts as necessary. Common issues such as noise, vibration, or belt wear can often be addressed through proper maintenance practices. Troubleshooting these issues typically involves identifying the source of the problem and taking corrective action, such as adjusting the belt tension or replacing worn components.

Common Issues and Solutions

Common issues that may arise with the Cummins Alternator Pulley 4009258 include belt slippage, pulley misalignment, and bearing failure. These issues can often be prevented through regular maintenance and by following proper installation procedures. Solutions may involve adjusting the belt tension, realigning the pulley, or replacing faulty components. Preventive measures include regular inspections and maintenance to identify and address potential issues before they become serious problems.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a strong reputation in the industry for producing high-quality automotive components. The company has a history of innovation and commitment to quality, which is reflected in its products, including the Cummins Alternator Pulley 4009258. This commitment ensures that Cummins components meet the demanding requirements of commercial truck operations, providing reliable performance and durability 3.

Compatibility with Cummins Engines

The Cummins Alternator Pulley part number 4009258 is designed to fit seamlessly with several models of Cummins engines, ensuring efficient power transmission and reliable alternator operation. This alternator pulley is compatible with the K19 series engines, including the K19 CM2350, K19 CM500, and K19 CM850 MCRS.

For the K19 CM2350, the part 4009258 is engineered to match the specific design and requirements of this engine model, providing a precise fit that enhances the alternator’s performance. Similarly, for the K19 CM500 and K19 CM850 MCRS, the pulley is tailored to ensure optimal engagement with the alternator, facilitating smooth operation and reducing wear and tear.

In the QSK19 series, the alternator pulley part number 4009258 is also a perfect match for the QSK19 CM2350, QSK19 CM500, and QSK19 CM850 MCRS engines. This compatibility ensures that the alternator pulley functions effectively within the engine’s framework, contributing to the overall efficiency and longevity of the engine.

By using the Cummins Alternator Pulley part number 4009258, users can expect a reliable and durable component that integrates well with these Cummins engine models, providing consistent performance and ease of maintenance.

Understanding the Role of Part 4009258 Alternator Pulley in Engine Systems

The alternator pulley, identified by part number 4009258, is an integral component in the efficient operation of engine systems. This pulley is specifically designed to facilitate the transfer of mechanical energy from the engine’s drive system to the alternator, ensuring that the alternator operates at the correct speed to generate electricity.

Integration with the Drive System

The alternator pulley is mounted on the alternator’s shaft and is driven by a belt connected to the engine’s crankshaft pulley. This setup ensures that as the engine runs, the crankshaft’s rotational motion is transmitted through the belt to the alternator pulley. The pulley’s design allows it to maintain the necessary speed ratio between the engine and the alternator, optimizing electrical output.

Interaction with the Alternator

Once the mechanical energy is transferred to the alternator via the pulley, the alternator converts this energy into electrical power. This electricity is essential for charging the vehicle’s battery and powering the electrical systems while the engine is running. The pulley’s role is to ensure that the alternator receives a consistent and appropriate amount of mechanical input, allowing it to function effectively.

Accessory Drive Considerations

In many engine systems, the alternator pulley is part of a larger accessory drive system that may include other components such as the power steering pump, air conditioning compressor, and water pump. The alternator pulley must be precisely aligned and tensioned within this system to avoid belt slippage or excessive wear. Proper installation and maintenance of the pulley are vital for the smooth operation of all accessories driven by the engine’s belt system.

Summary of Component Interaction

- Drive System: The alternator pulley interfaces directly with the engine’s drive belt, converting the crankshaft’s rotational energy into mechanical input for the alternator.

- Alternator: The pulley ensures the alternator operates at the optimal speed for efficient electrical generation.

- Accessory Drive: The pulley is a key component in the accessory drive system, working in concert with other pulleys to power various engine accessories.

Understanding these interactions highlights the importance of the alternator pulley in maintaining the overall functionality and efficiency of the engine system.

Conclusion

The Cummins Alternator Pulley 4009258 is a critical component in the alternator system of commercial trucks. Its robust design, compatibility with various Cummins engines, and role in efficient energy transfer contribute to the reliable operation of the truck’s electrical system. Proper installation, regular maintenance, and understanding of common issues and solutions are essential for maximizing the performance and longevity of this part.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019.

↩ -

Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body, David C Barton and John D Fieldhouse, Elsevier, 2009.

↩ -

Injection Technologies: Mixture Formation Strategies, Alessandro Ferrari and Pietro Pizzo, SAE International, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.