4086640

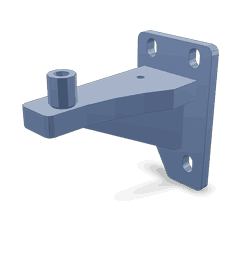

Alternator Bracket

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4086640 Alternator Bracket is a component designed for use in commercial trucks. Its primary role is to securely mount the alternator to the engine, ensuring stable operation and efficient power generation for the vehicle’s electrical system.

Purpose and Function

The Cummins 4086640 Alternator Bracket serves to support the alternator, which is responsible for generating electrical power to charge the battery and power the truck’s electrical components. By providing a stable mounting point, the bracket helps maintain the alternator’s alignment and reduces vibrations that could affect its performance. This contributes to the overall reliability and efficiency of the truck’s electrical system 1.

Key Features

This Cummins part is engineered with several key features that enhance its performance and durability. It is constructed from high-strength materials to withstand the rigors of commercial truck operation. The design includes precise mounting points and brackets that ensure a secure fit, minimizing the risk of alternator misalignment. Additionally, the bracket is designed to accommodate various alternator models, providing versatility for different truck applications 2.

Benefits

Using the Cummins 4086640 Alternator Bracket offers several benefits. It provides improved reliability by ensuring the alternator remains securely mounted, even under demanding conditions. The bracket’s design contributes to enhanced performance by reducing vibrations and maintaining proper alternator alignment. Additionally, the bracket is designed for ease of installation, allowing for quick and straightforward replacement or upgrade of the alternator.

Installation Process

Installing the Cummins 4086640 Alternator Bracket involves several steps. Begin by ensuring the engine is cool and the electrical system is disconnected to prevent any risk of electrical shock. Remove the old bracket if replacing, and align the new bracket with the mounting points on the engine. Secure the bracket using the provided fasteners, ensuring they are tightened to the manufacturer’s specified torque settings. Reinstall the alternator, connecting it to the bracket and ensuring all electrical connections are secure. Finally, re-enable the electrical system and test the alternator for proper operation.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 4086640 Alternator Bracket involves inspecting it for signs of wear or damage, such as cracks or loose fasteners. Ensure that all connections are tight and that the alternator remains properly aligned. Common issues may include vibrations, which can indicate a loose bracket or misaligned alternator. Addressing these issues promptly can prevent further damage and ensure the electrical system operates efficiently 3.

Performance Impact

The Cummins 4086640 Alternator Bracket plays a role in the overall performance of the truck’s electrical system by ensuring the alternator operates efficiently and reliably. A well-mounted alternator can lead to improved electrical system efficiency, reduced risk of electrical failures, and enhanced overall truck performance. The bracket’s design contributes to these benefits by providing a stable and secure mounting solution.

Safety Considerations

When installing or maintaining the Cummins 4086640 Alternator Bracket, it is important to follow safety protocols. Ensure the engine is cool before beginning work to avoid burns. Disconnect the electrical system to prevent electrical shock. Use the appropriate tools and follow torque specifications to avoid over-tightening, which can damage the bracket or engine components. Always wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against injuries.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company is committed to advancing technology and providing solutions that meet the evolving needs of its customers, ensuring they can operate efficiently and sustainably.

Cummins Alternator Bracket 4086640 Compatibility

The Cummins Alternator Bracket part number 4086640 is designed to fit a range of Cummins engines, ensuring a secure and reliable mounting for the alternator. This bracket is compatible with several models within the Cummins QSK series, specifically:

- QSK45 CM500

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK78 CM500

For the QSK45 CM500 and QSK60 CM500 engines, the alternator bracket 4086640 provides a robust mounting solution, ensuring the alternator is securely fastened to the engine block. This bracket is engineered to withstand the operational stresses of these engines, maintaining alignment and efficiency.

In the case of the QSK60 CM850 MCRS engine, the alternator bracket 4086640 is tailored to fit the specific design and mounting requirements of this model. The MCRS designation indicates a variant with specific features, and the bracket is designed to accommodate these differences while ensuring a reliable fit.

Lastly, for the QSK78 CM500 engine, the alternator bracket 4086640 is engineered to provide a secure mounting solution. This bracket is designed to fit seamlessly with the engine’s architecture, ensuring the alternator is properly positioned and secured.

Each of these engines benefits from the use of the 4086640 alternator bracket, which is crafted to meet the stringent requirements of Cummins’ high-performance engines. This compatibility ensures that the alternator operates efficiently and reliably, contributing to the overall performance and longevity of the engine.

Role of Part 4086640 Alternator Bracket in Engine Systems

The 4086640 Alternator Bracket is an integral component in the assembly and functionality of engine systems, specifically in relation to the alternator and its mounting. This bracket serves as a secure attachment point for the alternator, ensuring it is properly positioned and aligned within the engine bay.

When integrating the 4086640 Alternator Bracket into an engine system, it interfaces directly with the engine block or other structural components to provide a stable foundation for the alternator. This stability is essential for the alternator’s operation, as it must maintain consistent rotational speed and alignment with the engine’s crankshaft via the serpentine belt.

The bracket also plays a significant role in managing the electrical connections between the alternator and the engine’s electrical system. By holding the alternator in place, it ensures that the wiring harnesses and connectors remain taut and secure, preventing any potential damage from movement or vibration.

Furthermore, the 4086640 Alternator Bracket contributes to the overall balance and weight distribution of the engine components. Its design allows for efficient heat dissipation from the alternator, which is vital for maintaining optimal operating temperatures and preventing overheating.

In summary, the 4086640 Alternator Bracket is a key component in the engine system, facilitating the proper mounting and operation of the alternator, ensuring electrical integrity, and contributing to the engine’s thermal management.

Conclusion

The Cummins 4086640 Alternator Bracket is a vital component in the efficient and reliable operation of commercial truck electrical systems. Its robust design, compatibility with various Cummins engines, and ease of installation make it an essential part for maintaining the performance and longevity of truck engines. Regular maintenance and adherence to safety protocols during installation and troubleshooting are crucial for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.