4350111

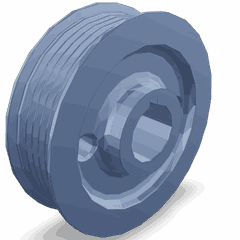

Alternator Pulley

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4350111 Alternator Pulley, manufactured by Cummins, is a critical component for the operation of commercial trucks. Cummins is renowned in the automotive industry for its commitment to quality and innovation. This alternator pulley is engineered to ensure the efficient functioning of the truck’s electrical system, contributing to the overall performance and reliability of the vehicle.

Basic Concepts of Alternator Pulleys

An alternator pulley is a component that facilitates the operation of the alternator within a vehicle’s electrical system. It is connected to the engine via a belt and works in tandem with the alternator to generate electrical power. The pulley’s rotation drives the alternator, which in turn produces electricity to power the vehicle’s electrical systems and recharge the battery. The interaction between the alternator pulley, alternator, and engine belt is essential for maintaining the vehicle’s electrical supply 1.

Purpose of the 4350111 Alternator Pulley

The 4350111 Alternator Pulley serves a specific function within the truck’s operation. It is responsible for driving the alternator, ensuring that it spins at the correct speed to generate the necessary electrical power. This power is vital for operating the truck’s electrical components, including lights, radio, and other systems, as well as for recharging the battery. The efficient transfer of mechanical energy from the engine to the alternator via the pulley is fundamental to the truck’s electrical system functionality 2.

Key Features

The 4350111 Alternator Pulley is characterized by its robust design and construction. It is made from high-quality materials that ensure durability and reliability under the demanding conditions of commercial truck operation. The pulley’s design includes precision engineering to ensure smooth operation and efficient power transfer. Its construction is tailored to withstand the rigors of heavy-duty use, contributing to the overall performance and longevity of the truck’s electrical system 3.

Benefits

The 4350111 Alternator Pulley offers several advantages. Its design enhances the efficiency of the electrical system by ensuring optimal power transfer from the engine to the alternator. The pulley’s reliability is paramount for the consistent operation of the truck’s electrical components. Additionally, its compatibility with Cummins engines ensures seamless integration and performance, making it a valuable component for trucks equipped with Cummins power units 4.

Installation Considerations

When installing the 4350111 Alternator Pulley, it is important to follow guidelines and best practices to ensure proper function. This includes aligning the pulley correctly with the alternator and engine, tensioning the engine belt to the manufacturer’s specifications, and verifying compatibility with the truck’s engine and alternator. Proper installation is key to maintaining the efficiency and reliability of the truck’s electrical system.

Troubleshooting Common Issues

Common problems associated with alternator pulleys can include squeaking, wobbling, or failure to engage. These issues may arise from misalignment, worn bearings, or belt tension problems. Diagnostic steps should include inspecting the pulley and belt for wear, ensuring proper alignment, and checking the tension of the belt. Addressing these issues promptly can prevent further damage and ensure the continued operation of the truck’s electrical system.

Maintenance Tips

Routine maintenance of the 4350111 Alternator Pulley is important for ensuring optimal performance and longevity. This includes regular inspection for signs of wear, lubrication of moving parts as necessary, and adhering to recommended replacement intervals. Maintaining the pulley in good condition contributes to the efficient operation of the truck’s electrical system and helps prevent unexpected failures.

Cummins Overview

Cummins Inc. is a leader in the commercial truck industry, with a history of innovation and quality. The company offers a wide range of products, including engines, filtration, emissions solutions, and power generation equipment. Cummins’ commitment to quality and performance is evident in its product offerings, which are designed to meet the demanding requirements of commercial truck applications. The 4350111 Alternator Pulley is a testament to Cummins’ dedication to providing reliable and high-performing components for the automotive industry.

Cummins Alternator Pulley 4350111 Compatibility

The Cummins Alternator Pulley part number 4350111 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This part is engineered to work with the following engines:

QSK95 Series

The QSK95 series engines are known for their robust design and high power output. The 4350111 alternator pulley is specifically tailored to fit these engines, providing a secure and efficient connection to the alternator. This ensures that the alternator can operate at peak efficiency, maintaining the necessary power supply for the vehicle’s electrical systems.

CM2350 Engines

The CM2350 engines are part of Cummins’ medium-duty engine lineup, recognized for their durability and performance in various applications. The 4350111 alternator pulley is compatible with these engines, ensuring that the alternator functions correctly. This compatibility is crucial for maintaining the electrical systems’ integrity, especially in demanding environments.

K111 Engines

The K111 engines are another example of Cummins’ commitment to providing reliable and efficient power solutions. The 4350111 alternator pulley is designed to fit these engines, ensuring that the alternator can operate smoothly. This compatibility is essential for maintaining the electrical systems’ functionality, providing consistent power to the vehicle’s components.

By ensuring that the 4350111 alternator pulley fits these engines, Cummins maintains a high standard of compatibility and performance across its engine lineup. This attention to detail helps ensure that the alternator can operate efficiently, providing the necessary power to the vehicle’s electrical systems.

Role of Part 4350111 Alternator Pulley in Engine Systems

The alternator pulley, identified by part number 4350111, is an integral component in the efficient operation of engine systems. It serves as the connection point between the engine’s drive system and the alternator.

When the engine operates, the drive belt transfers rotational force from the crankshaft to the alternator pulley. This pulley is mounted on the alternator’s shaft. As the pulley rotates, it drives the alternator, which in turn generates electrical power to charge the battery and power the vehicle’s electrical systems.

The alternator pulley must maintain precise alignment and tension with the drive belt to ensure optimal performance. Proper engagement between the pulley and the belt is essential for consistent alternator operation, which directly impacts the reliability of the vehicle’s electrical system.

In summary, the alternator pulley plays a significant role in the seamless integration of the drive system and the alternator, ensuring that the engine’s mechanical energy is effectively converted into electrical energy.

Conclusion

The 4350111 Alternator Pulley is a vital component in the operation of commercial trucks, ensuring the efficient functioning of the electrical system. Its robust design, compatibility with Cummins engines, and role in the engine system make it an essential part for maintaining the performance and reliability of the vehicle. Proper installation, maintenance, and troubleshooting are key to ensuring the longevity and efficiency of this Cummins part.

-

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.