This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

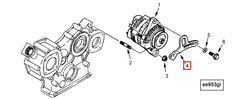

The 4900460 Alternator Bracket, manufactured by Cummins, is a critical component in the commercial truck parts industry. This part is essential for maintaining the integrity and efficiency of a truck’s electrical system. Cummins is known for its high-quality automotive components, and the 4900460 Alternator Bracket exemplifies this reputation, offering reliability and performance for commercial vehicles 1.

Basic Concepts of Alternator Brackets

An alternator bracket serves as a mounting point for the alternator within a vehicle’s electrical system. It secures the alternator to the engine, allowing it to spin and generate electricity. The bracket interfaces with both the alternator and the engine, ensuring that the alternator remains in the correct position and operates efficiently 2.

Purpose of the 4900460 Alternator Bracket

The 4900460 Alternator Bracket is designed to hold the alternator in place on a truck, ensuring it functions correctly within the vehicle’s electrical system. By securing the alternator, the bracket contributes to the stable and efficient generation of electrical power, which is vital for the operation of various electrical components in the truck 3.

Key Features

This Cummins part is constructed from materials that offer durability and resistance to the harsh conditions often encountered in commercial trucking. Its design includes features that enhance its strength and longevity, such as reinforced mounting points and a robust frame. These attributes help differentiate it from other alternator brackets, providing a reliable solution for truck operators.

Benefits

The 4900460 Alternator Bracket offers several benefits, including improved reliability of the electrical system due to its secure mounting of the alternator. It is designed for ease of installation, which can reduce downtime for truck maintenance. Additionally, by ensuring the alternator operates efficiently, the bracket can contribute to the overall performance and longevity of the truck.

Installation Process

Installing the 4900460 Alternator Bracket involves several steps to ensure a secure and effective fit. The process requires specific tools, and it is important to follow best practices to avoid common installation errors. Proper installation is key to ensuring the alternator operates efficiently and the electrical system remains reliable.

Troubleshooting and Maintenance

Common issues with alternator brackets can include loosening over time or damage from vibrations. Diagnosing these problems involves inspecting the bracket for signs of wear or misalignment. Regular maintenance, such as checking the tightness of the mounting bolts and ensuring the bracket is free from damage, can help prolong the life of the 4900460 Alternator Bracket.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles.

Cummins Alternator Bracket 4900460 Compatibility

The Cummins Alternator Bracket part number 4900460 is designed to fit a range of Cummins engines, ensuring a secure and reliable connection between the alternator and the engine block. This bracket is essential for maintaining the alternator’s position and function, which is vital for the proper operation of the engine’s electrical system.

A1400 and A1700 Engines

For the A1400 and A1700 engines, the 4900460 bracket is engineered to align perfectly with the mounting points on these engines. These engines, known for their robust performance and reliability, benefit from the precision fit of this bracket, which helps in reducing vibration and ensuring consistent alternator output.

A2000 and A2300 Engines

Similarly, the A2000 and A2300 engines are compatible with the 4900460 alternator bracket. These engines, which are part of a higher power range, require a sturdy and precise mounting solution to handle the increased load and stress. The bracket’s design accommodates the specific dimensions and requirements of these engines, ensuring that the alternator operates efficiently and reliably under various conditions.

Grouping by Engine Series

When considering the A1400 and A1700 engines together, it is evident that the 4900460 bracket provides a consistent fit across this series. This compatibility simplifies maintenance and repair processes, as technicians can use the same bracket for multiple engine models within this range.

The A2000 and A2300 engines, while part of a higher power series, also benefit from the 4900460 bracket’s design. The bracket’s ability to handle the increased demands of these engines ensures that the alternator remains securely mounted, contributing to the overall performance and longevity of the engine.

By using the Cummins Alternator Bracket part number 4900460, technicians and operators can ensure that their engines maintain optimal electrical system performance, regardless of the specific engine model.

Role of Part 4900460 Alternator Bracket in Engine Systems

The 4900460 Alternator Bracket is a critical component that facilitates the secure mounting of the alternator within various engine systems. Its primary function is to provide a stable and vibration-resistant platform for the alternator, ensuring efficient operation and longevity of the electrical system.

When integrated into an engine system, the 4900460 Alternator Bracket interfaces directly with the engine block or other structural components, offering a robust connection point. This bracket typically features mounting points for the alternator’s bolts, aligning it correctly with the engine’s accessory drive belt.

The alternator, once mounted on the bracket, relies on the consistent and precise positioning provided by the bracket to engage with the drive belt. This engagement is vital for the alternator’s rotor to spin, generating electrical power that charges the battery and powers the vehicle’s electrical systems.

Additionally, the 4900460 Alternator Bracket often includes provisions for electrical connections, ensuring that the alternator can communicate effectively with the vehicle’s electrical system. This includes connections for the battery cable and the regulator wire, which monitors and adjusts the alternator’s output to maintain optimal voltage levels.

Conclusion

In summary, the 4900460 Alternator Bracket plays a significant role in maintaining the structural integrity and operational efficiency of the alternator within the engine system. Its design ensures that the alternator remains securely in place, allowing it to perform its function without interference from engine vibrations or movement.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.