This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

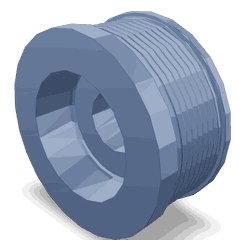

The Cummins 4938715 Alternator Pulley is a component designed for use in commercial trucks, specifically within the alternator system. Its purpose is to facilitate the efficient operation of the alternator by transferring rotational force from the engine to the alternator. This transfer is vital for generating electrical power, which is used to charge the vehicle’s battery and power electrical systems while the engine is running. The significance of this Cummins part lies in its role in ensuring the alternator operates effectively, thereby contributing to the overall reliability and performance of the truck 1.

Basic Concepts of Alternator Pulleys

An alternator pulley is a mechanical component that connects the alternator to the engine’s crankshaft or a dedicated drive belt. It functions by allowing the alternator to spin at a speed proportional to the engine’s RPM (revolutions per minute), which is necessary for the alternator to generate electrical power. The alternator pulley’s role within the alternator system is to maintain the correct tension and alignment of the drive belt, ensuring efficient power transmission and alternator operation 2.

Purpose of the 4938715 Alternator Pulley

This part plays a specific role in the operation of a truck by interfacing with the alternator and the belt drive system. It is designed to ensure that the alternator receives the necessary rotational force from the engine to generate electricity. This pulley is engineered to work in harmony with the alternator, providing a smooth and efficient transfer of power that is crucial for the alternator’s performance. Its interaction with the belt drive system is also important, as it helps maintain the proper tension and alignment of the belt, which is essential for the alternator’s efficiency and durability 3.

Key Features

The 4938715 Alternator Pulley is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to wear and corrosion, ensuring longevity in demanding commercial truck environments. The design of the pulley includes precision-machined grooves that provide a secure grip on the drive belt, minimizing slippage and ensuring efficient power transmission. Additionally, the pulley may feature a unique design that reduces noise and vibration, contributing to a smoother operation of the alternator system.

Benefits

Using the 4938715 Alternator Pulley offers several benefits, including improved efficiency and reliability of the alternator system. Its precise design and high-quality materials contribute to enhanced performance, ensuring that the alternator operates at optimal efficiency. This results in more reliable electrical power generation, which is crucial for the operation of the truck’s electrical systems and the charging of its battery. The pulley’s durability also means reduced maintenance requirements and longer service life, providing value to truck operators.

Installation Process

Installing the 4938715 Alternator Pulley requires careful attention to ensure correct fitting and operation. The process involves loosening the tensioner on the drive belt to create enough slack for the pulley to be removed or installed. Once the old pulley is removed, the new Alternator Pulley should be aligned with the alternator and secured in place. The drive belt is then re-routed over the pulley, and the tensioner is adjusted to ensure the correct tension on the belt. It is important to follow the manufacturer’s instructions and use the appropriate tools to ensure a proper installation.

Troubleshooting Common Issues

Common problems that may arise with the 4938715 Alternator Pulley include noise, wear, or failure to engage properly with the drive belt. Noise can often be attributed to a loose or worn pulley, while wear may indicate the need for replacement. If the pulley fails to engage, it could be due to misalignment or a faulty tensioner. Troubleshooting steps include inspecting the pulley for signs of wear or damage, ensuring proper alignment with the alternator and drive belt, and checking the tensioner for correct operation. Addressing these issues promptly can help maintain the efficiency and reliability of the alternator system.

Maintenance Tips

Regular maintenance practices are important for ensuring the longevity and optimal performance of the 4938715 Alternator Pulley. This includes periodic inspection for signs of wear or damage, ensuring the drive belt is properly tensioned, and cleaning the pulley and surrounding components to remove any debris or contaminants. Following the manufacturer’s recommended maintenance intervals and procedures can help prevent issues and ensure the alternator system operates efficiently.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to quality and customer satisfaction is reflected in its products, including the 4938715 Alternator Pulley.

Compatibility

The 4938715 Alternator Pulley is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is crucial for the proper functioning of the alternator, which is responsible for charging the battery and powering the electrical systems of the vehicle.

ISL9 CM2150 SN Engines

The 4938715 is specifically engineered to integrate with the ISL9 CM2150 SN engines. These engines are known for their robust performance and reliability, making them a popular choice in various applications, including heavy-duty trucks and industrial machinery. The pulley’s design ensures a secure fit and efficient power transfer, contributing to the overall efficiency and longevity of the engine.

Grouping of Compatible Engines

While the primary focus here is on the ISL9 CM2150 SN engines, it is important to note that the 4938715 may also be compatible with other similar engine models within the Cummins lineup. This compatibility is due to the standardized design and engineering principles that Cummins employs across its engine range.

For users of other Cummins engines, it is advisable to consult the manufacturer’s specifications or a certified Cummins dealer to confirm the compatibility of part 4938715 with their specific engine model. This ensures that the alternator pulley will fit correctly and function as intended, maintaining the engine’s performance and reliability.

Role of Part 4938715 Alternator Pulley in Engine Systems

The 4938715 Alternator Pulley is an integral component in the efficient operation of engine systems, particularly in the context of alternator mounting. This pulley is designed to facilitate the transfer of rotational force from the engine’s crankshaft to the alternator.

When the engine operates, the crankshaft’s rotation is transmitted through a serpentine belt to the 4938715 Alternator Pulley. This pulley, in turn, drives the alternator, which is responsible for generating electrical power to charge the battery and power the vehicle’s electrical systems.

The pulley’s precise design ensures that the alternator maintains the correct speed and tension, which is essential for optimal performance. It interacts seamlessly with the alternator mounting bracket, securing the alternator in place while allowing for smooth rotation. This setup is vital for maintaining the balance and efficiency of the engine’s accessory drive system.

Additionally, the 4938715 Alternator Pulley works in conjunction with other pulleys and components within the engine bay, such as the crankshaft pulley, idler pulleys, and tensioner pulleys, to ensure a harmonized operation of the accessory drive belt. This coordination is key to preventing belt slippage and ensuring consistent power generation.

In summary, the 4938715 Alternator Pulley plays a significant role in the alternator mounting system, contributing to the reliable and efficient functioning of the engine’s electrical system.

Conclusion

The Cummins 4938715 Alternator Pulley is a critical component in the alternator system of commercial trucks, ensuring efficient power generation and reliable operation of the vehicle’s electrical systems. Its high-quality construction, precise design, and compatibility with various Cummins engine models make it a valuable part for maintaining the performance and reliability of commercial trucks. Regular maintenance and proper installation are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.