This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

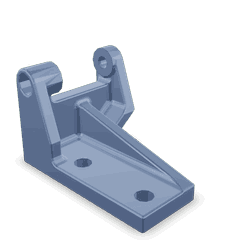

The 4986867 Alternator Bracket is a component manufactured by Cummins, a well-established name in the commercial truck parts industry. This bracket is designed to support the alternator in commercial trucks, ensuring the electrical system functions efficiently. Understanding its role and features is important for maintaining the vehicle’s performance and reliability.

Purpose and Function

The Alternator Bracket plays a role in the operation of a truck by securely holding the alternator in place. This support is vital for the alternator’s function, which is to generate electrical power for the vehicle’s systems and to recharge the battery. The bracket ensures that the alternator remains stable and aligned correctly, which is important for its efficient operation and the overall electrical health of the truck 1.

Key Features

This Cummins part is constructed with specific design and construction features that enhance its functionality. It is made from durable materials that can withstand the rigors of commercial truck use. The bracket includes precise mounting points that allow for secure attachment to the truck’s engine. Its design also incorporates features that facilitate easy installation and maintenance, ensuring that it can be serviced with minimal disruption to the vehicle’s operation 2.

Benefits

Using the 4986867 Alternator Bracket in truck applications offers several advantages. Its robust construction contributes to the durability of the component, reducing the likelihood of failure under stress. The design of the bracket also simplifies the installation process, allowing for quick and efficient replacement or upgrade. Additionally, its compatibility with Cummins engines ensures that it integrates seamlessly with the truck’s electrical system, maintaining optimal performance 3.

Installation Process

Installing the 4986867 Alternator Bracket requires careful attention to alignment and securing methods. The process involves positioning the bracket in the correct location on the engine, ensuring that it is level and aligned with the alternator. Once in place, the bracket is secured using the appropriate fasteners, which may require specific tools for proper installation. It is important to follow the manufacturer’s guidelines to ensure that the bracket is installed correctly and functions as intended.

Maintenance and Care

Regular maintenance of the Alternator Bracket is important to ensure its continued functionality. This includes inspecting the bracket for signs of wear or damage, cleaning it to remove any debris or corrosion, and tightening any fasteners that may have loosened over time. If the bracket shows significant wear or damage, it may be necessary to consider replacement to maintain the integrity of the truck’s electrical system.

Troubleshooting Common Issues

Common issues with the Alternator Bracket may include misalignment, loose fasteners, or damage from wear and tear. Signs of failure can manifest as electrical issues within the truck, such as dimming lights or a non-functioning battery. Diagnostic steps involve inspecting the bracket for physical damage, ensuring that all fasteners are secure, and checking the alignment of the alternator. Repair or replacement may be necessary if the bracket is found to be damaged or if it is contributing to electrical problems.

Compatibility and Applications

The 4986867 Alternator Bracket is designed for use with specific truck models and engine types. Its applicability in various commercial truck settings ensures that it can be relied upon to support the alternator effectively across a range of applications. Understanding the compatibility of the bracket with different truck models is important for ensuring that it meets the specific needs of the vehicle it is installed in.

Safety Considerations

When working with the Alternator Bracket, it is important to adhere to safety guidelines to protect both the technician and the vehicle. This includes observing electrical safety practices, handling the component with care to avoid damage, and following the manufacturer’s recommendations for installation and maintenance. Proper safety measures help to ensure that the installation process is conducted without incident and that the bracket functions safely within the truck’s electrical system.

Cummins: A Brief Overview

Cummins Inc. is a leader in the commercial truck industry, known for its commitment to quality and innovation in engine and component manufacturing. The company’s history is marked by a dedication to producing reliable and efficient parts that meet the demanding requirements of commercial trucking. Cummins’ role in the industry is underpinned by its focus on advancing technology and maintaining high standards in all its products, including the 4986867 Alternator Bracket.

Cummins Alternator Bracket 4986867 Compatibility

The Cummins Alternator Bracket part number 4986867 is designed to fit a variety of engine models, ensuring compatibility across different applications. This bracket is essential for securing the alternator in place, maintaining proper alignment and function of the engine’s electrical system.

N14 MECHANICAL

The N14 MECHANICAL engine benefits from the robust design of the 4986867 alternator bracket. This bracket provides the necessary support and stability, ensuring that the alternator operates efficiently and reliably.

NH/NT 855

For the NH/NT 855 engines, the 4986867 alternator bracket is engineered to fit seamlessly. This bracket’s precision ensures that the alternator is securely mounted, contributing to the engine’s overall performance and longevity.

QSN14 CM876 N103

The QSN14 CM876 N103 engine also utilizes the 4986867 alternator bracket. This bracket’s design is tailored to meet the specific requirements of this engine model, providing the necessary support and alignment for optimal alternator function.

By ensuring compatibility with these engine models, the Cummins Alternator Bracket 4986867 plays a critical role in maintaining the integrity and efficiency of the engine’s electrical system.

Role of Part 4986867 Alternator Bracket in Engine Systems

Part 4986867, the Alternator Bracket, is an essential component in the alternator mounting system of various engine setups. Its primary function is to securely hold the alternator in place, ensuring it remains stable during engine operation. This stability is vital for the alternator’s performance, as any movement can affect its efficiency in generating electrical power.

The Alternator Bracket interfaces directly with the engine block or other structural components, providing a solid foundation for the alternator. It is designed to distribute the forces generated by the alternator’s operation, preventing undue stress on the alternator itself and the electrical connections.

In addition to its structural role, the Alternator Bracket also facilitates the alignment of the alternator’s pulley with the engine’s belt system. Proper alignment is necessary for the efficient transfer of power from the engine to the alternator, ensuring optimal performance and longevity of both components.

Furthermore, the Alternator Bracket often includes provisions for electrical connections, such as wiring harnesses, which are essential for transmitting the generated electrical power to the battery and other electrical systems within the vehicle. This integration ensures a seamless flow of electricity, supporting the vehicle’s electrical demands.

Overall, the Alternator Bracket plays a significant role in maintaining the integrity and efficiency of the alternator within the engine system, contributing to the reliable operation of the vehicle’s electrical components.

Conclusion

The 4986867 Alternator Bracket is a critical component in the maintenance and operation of commercial trucks. Its robust design, ease of installation, and compatibility with various Cummins engines make it an invaluable part for ensuring the reliability and efficiency of the truck’s electrical system. Regular maintenance and adherence to safety guidelines are essential for maximizing the lifespan and performance of this Cummins part.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Department of Energy. Department of Energy Fundamentals Handbook. Department of Energy, 2015.

↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.