This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

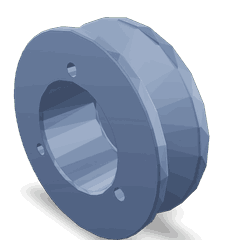

The Cummins 5254970 Alternator Pulley is a component designed for use in commercial trucks. Its purpose is to facilitate the operation of the alternator by transferring rotational force from the engine to the alternator. This transfer is vital for generating electrical power, which is used to charge the battery and power the vehicle’s electrical systems. The significance of the alternator pulley in the operation of commercial trucks lies in its role in ensuring a consistent and reliable supply of electrical power, which is essential for the truck’s performance and functionality 1.

Basic Concepts of Alternator Pulleys

An alternator pulley is a wheel-shaped component that is part of the engine’s accessory drive system. Its function is to connect the alternator to the engine via a serpentine belt. As the engine rotates, the pulley spins the alternator, which in turn generates electricity. The alternator pulley interacts with the alternator and the serpentine belt to maintain the proper tension and alignment necessary for efficient operation. This interaction ensures that the alternator receives the necessary rotational force to function correctly 2.

Purpose and Role in Truck Operation

This Cummins part plays a role in the operation of a truck by ensuring the alternator receives the necessary rotational force from the engine. This force is essential for the alternator to generate electricity, which is used to charge the truck’s battery and power its electrical systems. The alternator pulley’s contribution to the electrical system is significant, as it helps maintain a consistent supply of power, which is vital for the truck’s overall engine performance and functionality.

Key Features

The 5254970 is designed with several key features that enhance its performance and durability. These features include a robust construction that can withstand the high rotational speeds and forces encountered in commercial truck engines. The pulley is made from high-quality materials that offer resistance to wear and corrosion, ensuring long-lasting performance. Additionally, its design may include features such as a ribbed surface to improve belt grip and reduce the risk of slippage.

Benefits

Using this part offers several benefits. These include improved efficiency in power transmission from the engine to the alternator, which can lead to better overall electrical system performance. The pulley’s durable construction and high-quality materials contribute to its reliability and longevity, reducing the need for frequent replacements. Furthermore, its design may help in minimizing maintenance requirements, making it a cost-effective choice for commercial truck operators.

Installation Process

Installing the 5254970 requires careful attention to ensure proper fitting and function. The process involves removing the old pulley, if present, and aligning the new pulley with the alternator and engine. Tools such as a wrench and a pulley alignment tool may be required. It is important to ensure that the pulley is securely fastened and that the serpentine belt is correctly tensioned to prevent slippage and ensure efficient operation.

Maintenance Tips

To ensure optimal performance of the 5254970, regular maintenance is recommended. This includes inspecting the pulley for signs of wear or damage, cleaning it to remove any debris or buildup, and ensuring that the serpentine belt is in good condition and properly tensioned. Lubricating the pulley’s bearing, if applicable, can also help in maintaining smooth operation and extending its lifespan.

Troubleshooting Common Issues

Common problems associated with alternator pulleys include squeaking noises, which may indicate a loose or worn belt, and signs of wear or damage on the pulley itself. Troubleshooting these issues involves inspecting the pulley and belt for signs of wear, ensuring that the belt is properly tensioned, and replacing any worn or damaged components. Regular maintenance can help in preventing these issues and ensuring the pulley’s continued reliable operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, which are designed to meet the demanding requirements of commercial applications 3.

Cummins Alternator Pulley Part 5254970 Compatibility

The Cummins Alternator Pulley part number 5254970 is a critical component designed to work seamlessly with various Cummins engines. This part is engineered to ensure optimal performance and reliability across multiple engine models.

QSB3.3 CM2150

The QSB3.3 CM2150 engine is part of Cummins’ QSB series, known for its robust design and efficiency. The alternator pulley part 5254970 is specifically tailored to fit this engine model, ensuring that the alternator operates at peak efficiency. This compatibility is crucial for maintaining the electrical systems of the engine, providing consistent power to the vehicle’s electrical components.

Group Compatibility

The alternator pulley part 5254970 is also compatible with other engines within the Cummins QSB series. This part’s design allows it to fit various engine configurations, ensuring that the alternator can effectively charge the battery and power the vehicle’s electrical systems. The interchangeability of this part across different engine models highlights Cummins’ commitment to providing reliable and versatile components for their engines.

Role of Part 5254970 Alternator Pulley in Engine Systems

The alternator pulley, identified by part number 5254970, is an integral component in the efficient operation of engine systems. It is specifically designed to work in conjunction with the alternator and the engine’s mounting system to ensure optimal performance.

Interaction with the Alternator

The alternator pulley is directly connected to the alternator. Its primary function is to transfer rotational force from the engine to the alternator. This transfer is essential for the alternator to generate electrical power, which is used to charge the battery and power the vehicle’s electrical systems. The pulley’s design ensures that the alternator operates at the correct speed, maintaining a consistent electrical output.

Integration with the Engine Mounting System

The alternator pulley also plays a significant role in the engine’s mounting system. It is typically mounted on a bracket that is secured to the engine block. This mounting arrangement allows for the precise alignment of the pulley with the engine’s drive belt. Proper alignment is vital for the efficient transfer of power and to prevent excessive wear on both the pulley and the belt. The mounting system must be robust enough to handle the dynamic forces generated during engine operation while maintaining the pulley’s position.

Ensuring Smooth Operation

The interaction between the alternator pulley, alternator, and engine mounting system is designed to ensure smooth and reliable operation. The pulley’s bearing system reduces friction, allowing it to spin freely and efficiently. This is important for the longevity of the alternator and the overall health of the engine system.

Conclusion

In summary, the alternator pulley (part 5254970) is a key component that facilitates the transfer of mechanical energy to electrical energy within the engine system. Its proper function and integration with the alternator and mounting system are essential for the vehicle’s electrical and mechanical performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.