This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

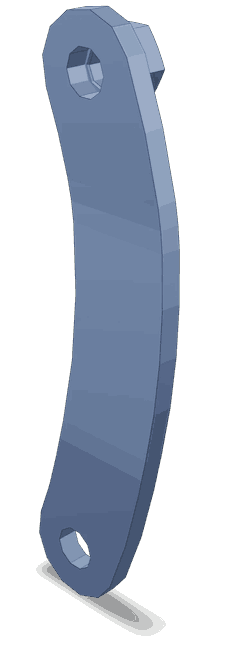

The Aftertreatment Bracket 5331777 is a component designed by Cummins to support and secure various elements within the aftertreatment system of commercial trucks. Its purpose is to ensure the proper positioning and stability of aftertreatment components, contributing to the overall efficiency and effectiveness of the system.

Basic Concepts of Aftertreatment Systems

Aftertreatment systems in commercial trucks are designed to reduce emissions and meet environmental regulations. Key components include the Diesel Particulate Filter (DPF), which captures particulate matter from exhaust gases, and the Selective Catalytic Reduction (SCR) system, which uses a chemical reaction to convert nitrogen oxides into nitrogen and water. These systems play a significant role in minimizing the environmental impact of diesel engines 1.

Role of the Aftertreatment Bracket

The Aftertreatment Bracket 5331777 is specifically engineered to support and secure aftertreatment components within the truck’s exhaust system. By providing a stable mounting point, it ensures that components like the DPF and SCR system remain in the correct position, which is vital for their optimal operation and durability 2.

Key Features of the Aftertreatment Bracket 5331777

The design of the Aftertreatment Bracket 5331777 incorporates several important features. It is constructed from materials that offer durability and resistance to corrosion, ensuring longevity even in harsh operating environments. The bracket is also designed to be compatible with a variety of aftertreatment components, allowing for versatile application across different truck models.

Benefits of Using the Aftertreatment Bracket 5331777

Utilizing the Aftertreatment Bracket 5331777 offers several advantages. It enhances the stability of aftertreatment components, which can lead to improved system efficiency. Additionally, the secure mounting provided by the bracket may reduce the need for frequent maintenance, contributing to lower overall operational costs 3.

Installation Considerations

When installing the Aftertreatment Bracket 5331777, it is important to follow guidelines to ensure proper integration. This includes aligning the bracket correctly, adhering to specified torque values for fastening, and ensuring compatibility with other aftertreatment components. Proper installation is key to maximizing the effectiveness of the aftertreatment system.

Troubleshooting Common Issues

Common issues with aftertreatment brackets may include misalignment or instability of components. Troubleshooting these problems involves checking the bracket’s positioning, ensuring all fasteners are properly tightened, and verifying that the bracket is compatible with the installed aftertreatment components. Addressing these issues promptly can help maintain system performance.

Maintenance Tips

Routine maintenance of the Aftertreatment Bracket 5331777 involves inspecting it for signs of wear or damage, ensuring that all fasteners remain tight, and verifying that aftertreatment components are securely mounted. Regular checks can help identify potential issues before they lead to system failures, contributing to the longevity and effectiveness of the aftertreatment system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong commitment to innovation, Cummins has been at the forefront of developing advanced diesel engine technology and aftertreatment systems, aiming to provide efficient, reliable, and environmentally responsible power solutions.

Aftertreatment Bracket 5331777 Compatibility with Cummins Engines

The Aftertreatment Bracket 5331777, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines. This bracket is a critical component in the aftertreatment system, ensuring proper alignment and support for the exhaust aftertreatment devices.

QSF2.8 CM2880 F104, QSF2.8 CM2880 F105, and QSF2.8 CM2880 F114

The Aftertreatment Bracket 5331777 is specifically engineered to fit the QSF2.8 CM2880 F104, QSF2.8 CM2880 F105, and QSF2.8 CM2880 F114 engines. These engines are part of the Cummins QSF2.8 series, which is known for its reliability and efficiency in various applications.

The bracket’s design ensures that it can be easily installed and removed, facilitating maintenance and repairs. It is constructed from high-quality materials that can withstand the harsh conditions of the engine compartment, including high temperatures and exposure to exhaust gases.

By providing a secure mounting point for the aftertreatment components, the 5331777 bracket helps maintain the integrity of the exhaust system. This is crucial for ensuring that the aftertreatment devices, such as the Diesel Exhaust Fluid (DEF) injector and the Selective Catalytic Reduction (SCR) system, operate effectively.

The compatibility of the Aftertreatment Bracket 5331777 with these engines underscores Cummins’ commitment to providing robust and reliable parts that enhance the performance and longevity of their engines.

Role of Part 5331777 Aftertreatment Bracket in Engine Systems

The part 5331777 Aftertreatment Bracket is an integral component in the assembly and securement of various engine system components. It provides a stable and reliable mounting point for the aftertreatment system, ensuring that all connected parts remain firmly in place under the dynamic conditions of engine operation.

Integration with Mounting Systems

The Aftertreatment Bracket is designed to interface with the engine’s mounting system. It secures the aftertreatment components, such as the Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) system, to the engine frame. This bracket ensures that these components are properly aligned and supported, minimizing vibrations and potential damage from engine movement.

Connection to the Alternator

In many engine configurations, the Aftertreatment Bracket also plays a role in the securement of the alternator. By providing additional support and a stable mounting point, the bracket helps maintain the alternator’s position relative to the engine. This is particularly important as the alternator is subject to significant rotational forces and vibrations during operation. The bracket’s robust design ensures that the alternator remains securely mounted, contributing to the overall reliability and efficiency of the electrical system.

Enhanced System Stability

The Aftertreatment Bracket contributes to the stability of the entire aftertreatment system. By offering a solid mounting solution, it allows for the efficient transfer of exhaust gases through the DPF and SCR without undue stress on the connections. This stability is essential for the proper functioning of these components, as any misalignment or movement can lead to reduced efficiency and potential failure.

Support for Additional Components

Beyond the primary components, the Aftertreatment Bracket may also support other ancillary parts within the aftertreatment system, such as sensors and wiring harnesses. By providing a secure base, it ensures that these components remain in their optimal positions, facilitating accurate readings and reliable performance.

Conclusion

In summary, the Aftertreatment Bracket 5331777 is a key element in the integration and support of various engine system components, enhancing the overall performance and durability of the engine. Its role in securing aftertreatment components, supporting the alternator, and contributing to system stability underscores its importance in the efficient operation of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.