3014711

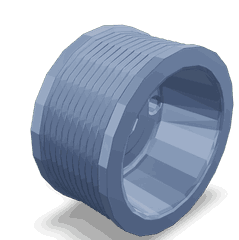

Alternator Pulley

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3014711 Alternator Pulley is a component designed for use in commercial trucks. It serves a specific function within the engine system, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Alternator Pulleys

An alternator pulley is a mechanical component that connects the alternator to the engine’s crankshaft. Its function is to transfer rotational force from the engine to the alternator, enabling the alternator to generate electrical power. This power is essential for charging the vehicle’s battery and powering electrical systems while the engine is running. The alternator pulley plays a role in ensuring consistent and reliable electrical output by maintaining the necessary speed and tension on the alternator’s drive belt 1.

Purpose of the 3014711 Alternator Pulley

The 3014711 Alternator Pulley is specifically designed to interface with Cummins alternators in commercial truck applications. It facilitates the transfer of mechanical energy from the engine to the alternator, allowing the alternator to convert this energy into electrical power. This pulley ensures that the alternator operates at the correct speed to efficiently charge the battery and supply power to the truck’s electrical systems. Its design and placement are critical for maintaining the balance and efficiency of the engine’s accessory drive system.

Key Features

The 3014711 Alternator Pulley is constructed with precision engineering in mind. It is made from durable materials that can withstand the rigors of commercial truck operation. The pulley features a robust design that ensures longevity and reliable performance. Its construction includes high-quality bearings and a smooth surface to reduce friction and wear. These features contribute to the overall efficiency and durability of the pulley.

Benefits of Using the 3014711 Alternator Pulley

Utilizing the 3014711 Alternator Pulley offers several advantages. Its design enhances the efficiency of the alternator, leading to improved electrical system performance. The durable construction ensures longevity, reducing the need for frequent replacements. Additionally, the pulley’s smooth operation contributes to the overall reliability of the truck’s electrical system, supporting consistent performance under various operating conditions.

Installation Process

Installing the 3014711 Alternator Pulley requires careful attention to detail to ensure proper function and safety. The process involves loosening the alternator’s mounting bolts, aligning the pulley with the alternator’s shaft, and securing it in place. Tools such as a socket wrench and a belt tensioner may be required. It is important to follow the manufacturer’s guidelines for torque specifications and belt tension to ensure optimal performance and safety 2.

Troubleshooting Common Issues

Common issues with alternator pulleys can include belt slippage, unusual noises, or pulley misalignment. These problems may arise from wear and tear, improper installation, or external factors affecting the pulley’s operation. Addressing these issues may involve inspecting the pulley and belt for signs of wear, ensuring proper alignment and tension, or replacing damaged components. Regular maintenance and inspections can help prevent these issues from occurring.

Maintenance Tips

Regular maintenance of the 3014711 Alternator Pulley is important for ensuring its longevity and performance. This includes inspecting the pulley and belt for signs of wear or damage, ensuring proper belt tension, and cleaning the pulley to remove any debris or buildup. Lubricating the pulley’s bearings, if applicable, can also contribute to smooth operation. Following the manufacturer’s maintenance schedule and guidelines will help maintain the efficiency and reliability of the alternator pulley.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial and industrial applications.

Cummins Alternator Pulley 3014711 Compatibility

The Cummins Alternator Pulley part number 3014711 is designed to fit a variety of engines, ensuring compatibility across multiple models. This alternator pulley is engineered to work seamlessly with the following engines:

K19 Series

- K19

- QSK19 CM2350

- QSK19 CM500

- QSK19 CM850 MCRS

K38 Series

- K38

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

K50 Series

- K50

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

This pulley is a critical component in the alternator system, facilitating the conversion of mechanical energy into electrical energy. Its design ensures it can handle the specific demands of each engine model, providing reliable performance and longevity.

Role of Part 3014711 Alternator Pulley in Engine Systems

The part 3014711 Alternator Pulley is an essential component in the efficient operation of various engine systems. It facilitates the transfer of rotational energy from the engine’s crankshaft to the alternator, ensuring that the alternator can generate electrical power to charge the battery and power the vehicle’s electrical systems.

Integration with Alternator Mounting and Drive System

The alternator pulley is mounted on the alternator’s front, interfacing directly with the alternator mounting system. This setup allows for secure attachment and smooth operation. The pulley engages with the drive belt, which is typically a serpentine belt in modern vehicles. The drive belt transfers rotational force from the crankshaft to the alternator, enabling it to spin at the necessary speed to generate electricity.

Interaction with the Alternator

As the alternator pulley rotates, it drives the alternator’s rotor inside the stator, inducing a magnetic field that generates electrical current. This current is then rectified and regulated to charge the battery and supply power to the vehicle’s electrical components. The efficiency of this process is highly dependent on the precise fitting and smooth operation of the alternator pulley.

Position in the Engine Bay

The EBM (Engine Bay Module) location of the alternator pulley is strategically chosen to minimize belt length and reduce the risk of belt wear. Proper alignment and tension of the belt are essential for optimal performance, and the pulley plays a key role in maintaining this tension.

Mounting Considerations

The mounting of the alternator, which includes the pulley, must be robust enough to withstand the dynamic forces exerted by the rotating belt. The pulley’s design often incorporates features to dampen vibrations and reduce noise, contributing to a smoother and more reliable operation of the alternator.

Conclusion

The 3014711 Alternator Pulley is a pivotal component in the engine’s electrical system, ensuring that the alternator operates efficiently and reliably. Its role in transferring rotational energy and maintaining belt tension is fundamental to the vehicle’s overall performance.

-

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ -

Nicholas Goodnight and Kirk VanGelder, Automotive Braking Systems CDX Master Automotive Technician Series, Jones Bartlett Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.