This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

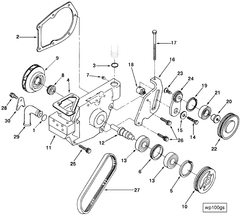

The Cummins 3062930 Idler Assembly is a component designed for use in heavy-duty trucks. It serves a specific function within the vehicle’s mechanical systems, contributing to the efficient operation of the truck. Understanding its purpose and significance is key to appreciating its role in maintaining the performance and reliability of heavy-duty trucks.

Basic Concepts of Idler Assemblies

An idler assembly is a mechanical component used in various systems to guide or redirect the path of a belt or chain. In the context of heavy-duty trucks, idler assemblies are integral to the belt drive systems, which are responsible for transmitting power to various components such as alternators, water pumps, and air conditioning compressors. The idler assembly ensures the belt remains properly tensioned and aligned, which is vital for the efficient transfer of power and the longevity of the belt and associated components 1.

Purpose of the Cummins 3062930 Idler Assembly

The Cummins 3062930 Idler Assembly plays a role in the truck’s belt drive system by maintaining the correct tension and alignment of the belts. This ensures efficient power transmission from the engine to auxiliary components. By keeping the belts properly tensioned, the idler assembly helps reduce slippage, which can lead to inefficiencies and increased wear on the belts and pulleys. Its function is crucial for the overall efficiency and performance of the vehicle, ensuring that all components driven by the belt operate smoothly and reliably 2.

Key Features

The Cummins 3062930 Idler Assembly is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to wear and corrosion, ensuring longevity in demanding environments. The design includes precision-machined components to ensure smooth operation and minimal friction. Additionally, the assembly may feature unique attributes such as adjustable tensioners or specialized coatings to further improve its performance under various operating conditions 3.

Benefits of Using the Cummins 3062930 Idler Assembly

Incorporating the Cummins 3062930 Idler Assembly into truck designs offers several advantages. It provides improved belt tension, which is essential for efficient power transmission and reducing the risk of belt failure. The reduction in wear and tear on the belts and pulleys leads to longer service intervals and lower maintenance costs. Furthermore, the assembly contributes to the overall reliability of the belt drive system, ensuring consistent performance under a wide range of operating conditions 4.

Installation Considerations

When installing the Cummins 3062930 Idler Assembly, it is important to follow guidelines and best practices to ensure optimal function. This includes using the necessary tools for proper setup and performing alignment checks to ensure the belt is correctly tensioned and aligned. Proper installation is vital to avoid issues such as belt slippage, increased wear, and potential failure of the belt drive system 5.

Maintenance and Troubleshooting

Regular maintenance routines are recommended to ensure the longevity and reliability of the Cummins 3062930 Idler Assembly. This includes periodic inspections for signs of wear or failure, such as cracks, excessive wear on the pulley, or misalignment. Troubleshooting common issues may involve adjusting the tension or replacing worn components to maintain optimal performance 6.

Performance Enhancements

The Cummins 3062930 Idler Assembly contributes to performance enhancements of the truck by ensuring efficient power transmission through the belt drive system. This leads to improved overall efficiency and longevity of associated components. By maintaining proper belt tension and alignment, the assembly helps reduce energy losses and wear, contributing to the truck’s reliability and performance 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of engines, components, and systems designed to meet the demanding requirements of heavy-duty applications 8.

Idler Assembly Part 3062930 for Cummins Engines

The Idler Assembly part 3062930, manufactured by Cummins, is a critical component in the engine systems of the N14 CELECT and N14 MECHANICAL engines. This part plays a pivotal role in maintaining the functionality and efficiency of the engine by ensuring proper belt tension and alignment.

In the N14 CELECT engine, the Idler Assembly is designed to work seamlessly with the engine’s electronic control system, providing the necessary support for the various ancillary components driven by the engine’s belt. The precision engineering of this part ensures that it can withstand the high operational stresses and temperatures typical of this engine model.

Similarly, in the N14 MECHANICAL engine, the Idler Assembly part 3062930 is engineered to integrate with the mechanical components of the engine. This assembly is crucial for maintaining the correct tension and alignment of the engine’s belt, which is essential for the proper functioning of the alternator, water pump, and other belt-driven accessories.

Both engine models benefit from the robust design and high-quality materials used in the construction of the Idler Assembly. This ensures longevity and reliability, reducing the likelihood of unexpected downtime due to mechanical failures.

The compatibility of the Idler Assembly with both the N14 CELECT and N14 MECHANICAL engines highlights its versatility and importance in maintaining the overall performance of these engine systems.

Role of Part 3062930 Idler Assembly in Engine Systems

The 3062930 Idler Assembly is an essential component in maintaining the efficiency and reliability of various engine systems, particularly when integrated with the water pump.

In engine systems, the water pump is responsible for circulating coolant throughout the engine to regulate temperature and prevent overheating. The 3062930 Idler Assembly works in conjunction with the water pump by providing the necessary tension to the serpentine belt that drives the pump. This ensures consistent and reliable operation of the water pump, allowing it to perform its cooling function effectively.

Additionally, the idler assembly helps in reducing belt wear and noise by maintaining proper belt tension. This is particularly important in high-performance engines where the water pump operates under greater stress and at higher speeds. The 3062930 Idler Assembly ensures that the serpentine belt remains in optimal condition, thereby extending the lifespan of both the belt and the water pump.

Furthermore, the integration of the 3062930 Idler Assembly with the water pump contributes to the overall stability and balance of the engine’s accessory drive system. By keeping the belt properly aligned and tensioned, the idler assembly minimizes the risk of belt slippage, which can lead to inefficient operation of the water pump and other driven components.

In summary, the 3062930 Idler Assembly plays a significant role in enhancing the performance and durability of the water pump within engine systems, ensuring smooth and efficient operation.

Conclusion

The Cummins 3062930 Idler Assembly is a vital component in the maintenance and operation of heavy-duty trucks and engines. Its role in ensuring proper belt tension and alignment contributes to the efficient transfer of power, reduced wear on components, and overall reliability of the vehicle. By understanding and properly maintaining this part, truck operators can ensure the longevity and performance of their vehicles.

-

Reducing Particulate Emissions in Gasoline Engines, Thorsten Boger, Willard Cutler, SAE International, 2018

↩ -

Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Robert Bosch GmbH, Springer Vieweg, 2007

↩ -

Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines, Hua Zhao, CRC Press, 2010

↩ -

PowerGen QSX15 CM2250, Bulletin Number 4310666, Operation and Maintenance Manual

↩ -

PowerGen QSX15 CM2250, Bulletin Number 4310666, Operation and Maintenance Manual

↩ -

PowerGen QSX15 CM2250, Bulletin Number 4310666, Operation and Maintenance Manual

↩ -

PowerGen QSX15 CM2250, Bulletin Number 4310666, Operation and Maintenance Manual

↩ -

PowerGen QSX15 CM2250, Bulletin Number 4310666, Operation and Maintenance Manual

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.