This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3523321 Rotor Assembly is a component designed for use in the braking systems of heavy-duty trucks. It is integral to the operation of these vehicles, providing the necessary stopping power and control required for safe and efficient transportation. This part is engineered to withstand the rigorous demands of heavy-duty applications, ensuring reliable performance under various operating conditions 1.

Basic Concepts of Rotor Assemblies

A rotor assembly, also known as a brake disc, is a component of a vehicle’s braking system. It consists of a disc that rotates with the wheel and a caliper that clamps down on the disc to create friction, thereby slowing or stopping the vehicle. The rotor assembly includes several components, such as the rotor itself, the caliper, brake pads, and mounting hardware. These parts work together to convert kinetic energy into thermal energy through friction, which is then dissipated as heat 2.

Purpose of the 3523321 Rotor Assembly

The 3523321 Rotor Assembly plays a role in the braking system by providing a surface for the brake pads to contact. When the brake pedal is pressed, hydraulic pressure is applied to the caliper, which in turn presses the brake pads against the rotor. This action creates friction that slows down the rotation of the wheel, contributing to the vehicle’s stopping power and control. The design and material of the rotor are important for dissipating heat generated during braking, which helps maintain consistent performance and prevent brake fade 3.

Key Features

The 3523321 Rotor Assembly is characterized by several key features that enhance its performance. It is constructed from high-quality materials, such as cast iron or composite materials, which offer excellent heat dissipation and durability. The rotor’s design may include ventilation features, such as drilled or slotted patterns, to improve cooling and reduce the risk of warping. Additionally, the rotor is precision-machined to ensure a smooth and consistent braking surface, which is important for optimal performance.

Benefits of Using the 3523321 Rotor Assembly

Utilizing the 3523321 Rotor Assembly offers several advantages. Its robust construction and high-quality materials contribute to improved durability, ensuring long-lasting performance even under demanding conditions. The enhanced braking performance provided by this rotor assembly can lead to shorter stopping distances and better vehicle control. Additionally, the design features that promote efficient heat dissipation can reduce the likelihood of brake fade, further enhancing safety and reliability. Over time, the durability and performance of this rotor assembly may also result in potential cost savings by reducing the frequency of replacements and maintenance.

Installation Process

Proper installation of the 3523321 Rotor Assembly is vital to ensure optimal performance and safety. The process involves several steps, including preparing the wheel hub, aligning the rotor with the wheel studs, and securing it with the appropriate hardware. It is important to use the correct tools and follow safety precautions, such as ensuring the vehicle is properly supported and the brakes are disengaged before beginning the installation. Additionally, the rotor should be inspected for any damage or imperfections before installation, and the braking system should be tested after completion to verify proper function.

Maintenance Tips

To ensure the 3523321 Rotor Assembly maintains optimal performance and longevity, regular maintenance is recommended. This includes inspecting the rotor for signs of wear, such as grooves or uneven surfaces, and cleaning it to remove any brake dust or debris. It is also important to check the alignment and condition of the caliper and brake pads, as these components work in conjunction with the rotor. Following the manufacturer’s recommended inspection intervals and performing routine maintenance can help prevent issues and ensure the braking system operates efficiently.

Troubleshooting Common Issues

Common problems associated with rotor assemblies can include warping, cracking, or excessive wear. These issues may arise due to factors such as overheating, improper installation, or insufficient maintenance. To troubleshoot these problems, it is important to perform a thorough inspection of the rotor and related components. Signs of warping may be indicated by vibrations or pulsations when braking, while cracks or excessive wear can be visually identified. Addressing these issues promptly by replacing or repairing the affected parts can help restore the braking system’s performance and safety.

Cummins Corporation Overview

Cummins Corporation is a well-established company with a strong reputation in the automotive and heavy-duty truck industries. Founded in 1919, Cummins has a long history of innovation and quality in engine and power generation technologies. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, designed to meet the needs of various industries. Cummins is known for its commitment to excellence, reliability, and customer satisfaction, making it a trusted name in the field of automotive and heavy-duty truck components.

Conclusion

The Cummins 3523321 Rotor Assembly is a vital component in the braking systems of heavy-duty trucks, offering enhanced performance, durability, and safety. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential to ensure the optimal functioning of this part. Cummins Corporation’s reputation for quality and reliability further underscores the value of this rotor assembly in the automotive industry.

-

Road and Off-Road Vehicle Dynamics, Moustafa ElGindy and Zeinab ElSayegh, Springer Nature, 2023

↩ -

Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Alma Hillier, Oxford University Press, 2014

↩ -

Heavy Duty Truck Systems Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩

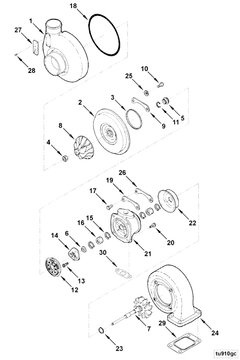

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.