This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The H1C Rotor Assembly, identified by part number 3545437, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industries. This rotor assembly is integral to the braking systems of heavy-duty trucks, contributing significantly to the safety and efficiency of these vehicles in commercial operations.

Purpose and Function

The H1C Rotor Assembly plays a role in the braking system of heavy-duty trucks by providing a surface for the brake pads to clamp onto, thereby facilitating the conversion of kinetic energy into thermal energy, which slows down or stops the vehicle 1. Its design ensures effective heat dissipation and consistent braking performance, which are vital for maintaining vehicle control under various driving conditions.

Key Features

The H1C Rotor Assembly is characterized by its robust design and construction. It is made from high-quality materials that offer superior resistance to wear and thermal stress. The assembly features a specific size and weight optimized for heavy-duty applications, ensuring it can withstand the rigors of commercial trucking. Unique attributes such as its vented design enhance cooling efficiency, contributing to its performance and durability.

Benefits

The advantages of the H1C Rotor Assembly include improved braking efficiency, which is crucial for the safety of heavy-duty trucks. Its durable construction ensures longevity, reducing the frequency of replacements and maintenance costs. The assembly’s reliability under demanding conditions typical of commercial trucking operations further adds to its value, providing operators with peace of mind 2.

Installation and Compatibility

Proper installation of the H1C Rotor Assembly is key to ensuring optimal performance and safety. Guidelines for installation include ensuring the rotor is correctly aligned and securely fastened to prevent any movement that could affect braking performance. Specific requirements may include the use of recommended lubricants and torque settings to maintain the integrity of the assembly and the braking system as a whole.

Maintenance and Troubleshooting

Maintaining the H1C Rotor Assembly involves regular inspections for signs of wear, damage, or warping. Best practices include cleaning the rotor surface to remove any debris that could interfere with braking performance and checking the thickness of the rotor to ensure it meets the minimum specifications for safe operation. Identifying common issues early, such as uneven wear or excessive heat, can prevent more serious problems and ensure continued safe and effective operation.

Performance in Various Conditions

The H1C Rotor Assembly is designed to perform under a wide range of driving conditions, including heavy loads, varied terrains, and extreme temperatures. Its ability to dissipate heat efficiently ensures consistent braking performance, even under the most demanding conditions. Operators should consider the specific challenges posed by their operating environment to ensure the rotor assembly remains in optimal condition.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industries. The company’s extensive product range and commitment to excellence make it a preferred choice for professionals in the field.

Conclusion

The H1C Rotor Assembly (part number 3545437) by Cummins is a critical component for the braking systems of heavy-duty trucks, offering enhanced safety, efficiency, and durability. Its robust design, coupled with the reputation of Cummins for quality and innovation, makes this part a valuable asset for commercial trucking operations. Proper installation, maintenance, and understanding of its performance capabilities under various conditions are essential for maximizing the benefits of this Cummins part.

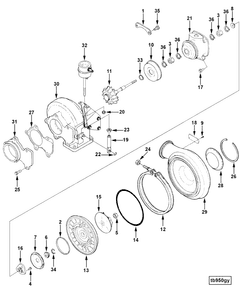

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.