This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

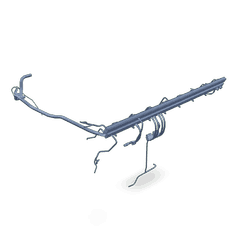

The Cummins 4998615 Wiring Top Level Assembly Harness is a specialized component designed for use in commercial trucks. It serves as a link in the electrical system, facilitating the connection between various electrical components and the truck’s power source. This harness is significant for maintaining the operational integrity of the truck’s electrical systems, ensuring that all connected devices function correctly and efficiently.

Basic Concepts of Wiring Top Level Assembly Harness

A Wiring Top Level Assembly Harness is a collection of wires, connectors, and terminals assembled into a single unit. This assembly is designed to route electrical signals and power throughout the truck. It includes various components such as wires of different gauges, connectors for joining wires, and terminals for connecting to electrical devices. The harness functions by providing a structured pathway for electrical current, ensuring that each component receives the correct voltage and amperage required for operation 1.

Purpose and Role in Truck Operation

The 4998615 Wiring Top Level Assembly Harness plays a role in the electrical system of a truck by connecting various electrical components, such as sensors, lights, and control units, to the truck’s power source. It ensures that these components receive the necessary electrical signals and power to function correctly. This harness is integral to the truck’s operation, as it allows for the coordination and communication between different electrical systems, contributing to the overall efficiency and safety of the vehicle 2.

Key Features

The 4998615 Wiring Top Level Assembly Harness is characterized by its robust design and the use of high-quality materials. It is constructed with durable wires that can withstand the harsh conditions often encountered in commercial truck environments. The harness also features corrosion-resistant connectors and terminals, which enhance its longevity and reliability. Additionally, its design allows for easy installation and maintenance, making it a practical choice for truck operators and maintenance personnel 3.

Benefits

The use of the 4998615 Wiring Top Level Assembly Harness offers several benefits. It contributes to improved reliability by ensuring that electrical connections are secure and consistent. This leads to enhanced efficiency in the truck’s electrical systems, as components operate with the correct voltage and amperage. Furthermore, the harness plays a role in safety by reducing the risk of electrical faults and failures, which can be hazardous in a commercial truck setting 4.

Installation Process

Installing the 4998615 Wiring Top Level Assembly Harness involves several steps. First, the existing wiring should be inspected for any damage or wear. The harness should then be routed through the truck, following the manufacturer’s guidelines for placement. Connections should be made using the provided connectors and terminals, ensuring that each connection is secure and properly insulated. It is important to test the harness after installation to confirm that all electrical components are functioning correctly.

Troubleshooting and Maintenance

To troubleshoot issues with the 4998615 Wiring Top Level Assembly Harness, it is important to first identify the symptoms of the problem. Common issues may include intermittent electrical failures or components not receiving power. Inspecting the harness for signs of wear, corrosion, or loose connections can help pinpoint the problem. Regular maintenance, such as cleaning connectors and checking for secure connections, can help prevent issues and ensure the longevity of the harness.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products, including engines, powertrains, and aftermarket parts, designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Cummins Wiring Top Level Assembly Harness (Part 4998615) in Engine Applications

The Cummins Wiring Top Level Assembly Harness, identified by part number 4998615, is a component in the electrical architecture of various Cummins engines. This harness is designed to integrate seamlessly with the engine’s electrical system, ensuring efficient power distribution and communication between different electrical components.

QSK60G Engine

In the QSK60G engine, the Wiring Top Level Assembly Harness (4998615) plays a role in managing the complex electrical demands of this high-performance engine. The harness is engineered to connect key electrical components, such as the engine control unit (ECU), sensors, and actuators, ensuring reliable and timely data transmission. This is important for maintaining optimal engine performance and efficiency, as well as for facilitating diagnostics and troubleshooting.

The harness is designed to withstand the harsh operational environments typical of heavy-duty engines like the QSK60G, which is often used in marine and industrial applications. Its robust construction and precise wiring ensure that electrical connections remain secure and reliable, even under extreme conditions.

Integration and Compatibility

The Wiring Top Level Assembly Harness (4998615) is designed to be compatible with a range of Cummins engines, including but not limited to the QSK60G. This compatibility is achieved through meticulous engineering and adherence to industry standards, ensuring that the harness can be integrated into various engine configurations without requiring significant modifications.

The harness is typically installed during the engine assembly process, with technicians carefully routing and securing the wiring to ensure that it does not interfere with other engine components. The precise routing and secure attachment points are important for maintaining the integrity of the electrical system and preventing potential issues such as short circuits or signal interference.

Importance in Engine Performance

The Wiring Top Level Assembly Harness (4998615) is integral to the overall performance and reliability of the engine. By providing a centralized and organized means of distributing electrical power and signals, the harness helps to ensure that all components receive the necessary power and information to operate correctly. This is particularly important in high-performance engines like the QSK60G, where precise and timely electrical communication can significantly impact performance and efficiency.

Role of Part 4998615 Wiring Top Level Assembly Harness in Engine Systems

The 4998615 Wiring Top Level Assembly Harness is an integral component in the orchestration of various engine systems, ensuring seamless communication and operation between different modules and the engine control unit (ECU).

Integration with Engine Control Unit (ECU)

The harness serves as the primary conduit for electrical signals between the ECU and other engine components. It facilitates the transmission of data that the ECU uses to manage fuel injection, ignition timing, and emissions controls. This ensures that the engine operates efficiently and within specified parameters.

Connection to Engine Modules

In addition to the ECU, the 4998615 harness interfaces with various engine modules such as the powertrain control module (PCM) and transmission control module (TCM). It allows these modules to exchange information necessary for optimal performance and smooth operation of the engine and transmission systems.

Role in Sensor Data Transmission

Sensors distributed throughout the engine system, such as the mass airflow sensor, oxygen sensor, and throttle position sensor, rely on the 4998615 harness to transmit real-time data to the ECU. This data is vital for the ECU to make instantaneous adjustments to engine parameters, ensuring consistent performance under varying conditions.

Facilitation of Actuator Commands

The harness also plays a key role in conveying commands from the ECU to actuators such as the fuel injectors, idle air control valve, and variable valve timing solenoids. This bidirectional flow of information and commands is essential for the precise control of engine functions.

Support for Ancillary Systems

Beyond the primary engine components, the 4998615 harness supports ancillary systems like the anti-lock braking system (ABS) and the electronic stability control (ESC) by providing the necessary electrical connections. This integration enhances overall vehicle safety and performance.

Conclusion

In summary, the 4998615 Wiring Top Level Assembly Harness is a fundamental element in the engine’s electrical system, enabling the complex interplay of data and commands that underpin modern engine management and vehicle operation.

-

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ -

Garrett, T. K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Hilgers, M. (2022). Transmissions and Drivetrain Design. Springer Vieweg.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.