This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4900828 Balancer Shaft is a component designed for heavy-duty truck engines. Its purpose is to enhance engine performance by mitigating vibrations and ensuring smoother operation. This balancer shaft is integral to maintaining the efficiency and longevity of the engine, contributing to overall vehicle reliability 1.

Basic Concepts of Balancer Shafts

A balancer shaft is a mechanical device used in internal combustion engines to reduce vibrations caused by the reciprocating motion of the pistons. It operates by rotating in the opposite direction of the crankshaft, counteracting the forces generated by the engine’s moving parts. This mechanism helps to stabilize the engine, leading to improved performance and reduced wear on engine components 2.

Purpose of the Cummins 4900828 Balancer Shaft

The Cummins 4900828 Balancer Shaft plays a specific role in the operation of a truck engine by reducing vibrations that occur due to the engine’s reciprocating components. By counteracting these vibrations, it enhances the smoothness of engine operation, which in turn contributes to better overall performance and driver comfort. This balancer shaft is engineered to work in harmony with the engine’s other components, ensuring that the engine runs as efficiently and quietly as possible 3.

Key Features

The Cummins 4900828 Balancer Shaft is distinguished by its robust design and the high-quality materials used in its construction. It features precision-machined components that ensure accurate fit and function within the engine. Additionally, the balancer shaft may include unique attributes such as advanced bearing systems or specialized coatings that enhance its durability and performance. These features contribute to its effectiveness in reducing engine vibrations and maintaining smooth operation.

Benefits of Using the Cummins 4900828 Balancer Shaft

Incorporating the Cummins 4900828 Balancer Shaft into a truck engine offers several advantages. It contributes to improved engine performance by minimizing vibrations, which can lead to increased efficiency and power output. Additionally, by reducing the stress on engine components, it helps to decrease wear and tear, potentially extending the engine’s lifespan. Enhanced driver comfort is another benefit, as the reduction in vibrations leads to a smoother ride.

Installation and Integration

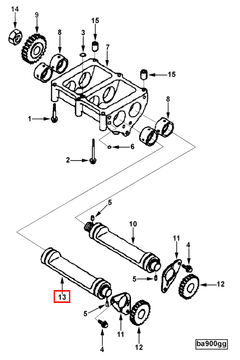

Installing the Cummins 4900828 Balancer Shaft into a truck engine requires careful attention to detail to ensure proper fit and function. The process involves aligning the balancer shaft with the engine’s crankshaft and securing it in place with the appropriate fasteners. It is important to follow manufacturer guidelines to ensure that the balancer shaft is installed correctly and operates as intended within the engine system.

Common Issues and Troubleshooting

Typical problems that may arise with the Cummins 4900828 Balancer Shaft include misalignment, wear on bearing surfaces, or issues with the balancer shaft’s rotation. Troubleshooting these issues may involve inspecting the balancer shaft for signs of wear or damage, ensuring that it is properly aligned with the crankshaft, and checking the condition of its bearings and fasteners. Addressing these issues promptly can help to maintain the balancer shaft’s effectiveness and the engine’s overall performance.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 4900828 Balancer Shaft, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or damage, ensuring that all fasteners are secure, and verifying that the balancer shaft is properly aligned with the crankshaft. Additionally, following the manufacturer’s recommended service intervals for lubrication and other maintenance tasks can help to keep the balancer shaft in top condition.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. The company’s product range includes engines for on-highway and off-highway applications, as well as components and systems that enhance engine performance and efficiency.

Cummins Balancer Shaft 4900828 in Engine Applications

The Cummins Balancer Shaft 4900828 is a critical component in maintaining engine stability and performance. This part is designed to reduce vibrations and ensure smooth operation in various engine configurations. Below is a detailed description of how this balancer shaft integrates with specific Cummins engines.

A2000 Engine Series

In the A2000 engine series, the balancer shaft 4900828 plays a pivotal role in mitigating the effects of engine imbalance. This engine series is known for its robust design and reliability, often used in heavy-duty applications. The balancer shaft works in conjunction with the crankshaft to counteract the forces generated by the pistons and connecting rods, thereby enhancing the engine’s longevity and efficiency.

A2300 Engine Series

Similarly, in the A2300 engine series, the balancer shaft 4900828 is integral to the engine’s operational integrity. This series is typically employed in demanding environments where consistent performance is crucial. The balancer shaft’s design ensures that the engine runs smoothly, reducing wear and tear on other components. Its precise engineering allows it to work seamlessly with the engine’s architecture, providing a balanced and stable power output.

Common Integration Aspects

Across both the A2000 and A2300 engine series, the balancer shaft 4900828 is engineered to fit precisely within the engine’s design parameters. This includes compatibility with the engine block, alignment with the crankshaft, and integration with other moving parts. The balancer shaft’s placement and operation are critical to achieving optimal engine performance and longevity.

The balancer shaft’s design ensures it can handle the specific demands of each engine series, providing a reliable solution to the challenges of engine vibration and imbalance. This part’s precision and durability make it a vital component in the Cummins engine lineup, ensuring that both the A2000 and A2300 engines operate at peak efficiency.

Role of Part 4900828 Balancer Shaft in Engine Systems

The balancer shaft, specifically part 4900828, is an integral component in the synchronization and smooth operation of an engine. This shaft is designed to counteract the inherent vibrations produced by the engine’s moving parts, ensuring a more stable and efficient performance.

When integrated into the engine system, the balancer shaft operates in conjunction with the primary balancer. The primary balancer typically manages the majority of the engine’s vibrational forces, but the addition of the balancer shaft, part 4900828, provides an extra layer of stability. This is particularly important in engines with higher displacements or those operating at elevated RPMs, where vibrations can significantly impact performance and longevity.

The balancer shaft is synchronized with the crankshaft, often rotating at twice the crankshaft’s speed but in the opposite direction. This counter-rotation helps to offset the forces generated by the pistons and connecting rods, leading to a more balanced engine operation.

In engines equipped with multiple cylinders, the balancer shaft plays a role in harmonizing the motion of each cylinder. By reducing the vibrational discrepancies between cylinders, it contributes to a more uniform power delivery and decreased mechanical stress on the engine components.

Furthermore, the balancer shaft interacts with other engine components such as the timing belt or chain. Proper alignment and timing are essential to ensure that the balancer shaft operates in phase with the crankshaft and other rotating assemblies. This synchronization is vital for maintaining the engine’s overall balance and preventing excessive wear on bearings and other critical parts.

In summary, part 4900828 balancer shaft is a key element in the engine’s vibration management system. Its effective integration and operation alongside the primary balancer and crankshaft are essential for achieving optimal engine performance and durability.

Conclusion

The Cummins 4900828 Balancer Shaft is a vital component in the operation of heavy-duty truck engines. By reducing vibrations and ensuring smoother engine operation, it contributes to improved performance, increased efficiency, and extended engine lifespan. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential to maximize the benefits of this part. Cummins’ commitment to innovation and quality ensures that the 4900828 Balancer Shaft remains a reliable and effective solution for engine vibration management.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.