This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

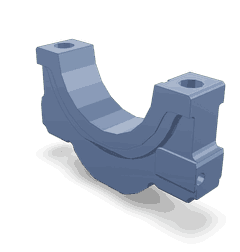

The Cummins 180158 Main Bearing Cap is a component designed to support the crankshaft in heavy-duty truck engines. Its role is significant in ensuring the smooth operation and longevity of the engine. By providing a stable foundation for the crankshaft, it contributes to the overall efficiency and reliability of the engine system 1.

Function and Operation

This Cummins part plays a role in supporting the crankshaft and maintaining engine stability. It is positioned to secure the main bearings, which are responsible for reducing friction between the crankshaft and the engine block. The cap interacts with the main bearings and the crankshaft journal, ensuring that the crankshaft remains aligned and operates smoothly within the engine block. This interaction is vital for the efficient transfer of power from the engine to the drivetrain 2.

Key Features

The Cummins 180158 Main Bearing Cap is characterized by its robust design, which includes a material composition that enhances durability and resistance to wear. The structural integrity of the cap is designed to withstand the high stresses and loads experienced during engine operation. Unique design elements, such as precision machining and surface treatments, are incorporated to improve performance and longevity. These features contribute to the cap’s ability to maintain a secure fit and provide consistent support to the crankshaft 3.

Benefits

The Cummins 180158 Main Bearing Cap offers several advantages that contribute to engine reliability and performance. By providing a stable platform for the crankshaft, it helps to reduce wear on the crankshaft journals, leading to longer engine life. The cap’s design also contributes to improved engine efficiency, as it ensures that the crankshaft operates within the intended parameters. Additionally, the enhanced stability provided by the cap can lead to smoother engine operation and reduced vibrations, further contributing to overall engine performance 4.

Installation and Maintenance

Proper installation of the Cummins 180158 Main Bearing Cap is crucial for ensuring optimal engine performance. Guidelines for installation include adhering to torque specifications and following alignment procedures to ensure the cap is securely fastened and properly positioned. Routine maintenance checks are recommended to verify the cap’s condition and ensure it continues to provide the necessary support to the crankshaft. These checks may include inspecting for signs of wear, ensuring proper alignment, and verifying that all fasteners are tightened to the specified torque 5.

Troubleshooting Common Issues

Common problems associated with Main Bearing Caps, such as oil leaks or excessive wear, can impact engine performance. Diagnostic procedures for identifying these issues may include visual inspections, measuring crankshaft deflection, and analyzing oil samples for metal particles. Repair procedures may vary depending on the specific issue but can include resurfacing the cap, replacing worn bearings, or addressing oil seal failures. Prompt identification and repair of these issues are important for maintaining engine health and performance 6.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a history of producing high-quality automotive components, particularly for heavy-duty trucks. The company’s reputation for reliability and performance is built on a foundation of innovation, quality manufacturing processes, and a commitment to customer satisfaction. Cummins components, including the 180158 Main Bearing Cap, are designed with these principles in mind, ensuring that they meet the demanding requirements of heavy-duty applications 7.

Cummins Main Bearing Cap 180158 Compatibility

The Cummins Main Bearing Cap part number 180158 is a critical component in ensuring the smooth operation of various engine configurations. This part is designed to fit seamlessly with the following Cummins engines:

V28 Engines

The Cummins V28 engine is a robust and powerful engine, often utilized in heavy-duty applications. The Main Bearing Cap 180158 is engineered to fit perfectly within the V28 engine, providing essential support and stability to the crankshaft. Its precision design ensures that it aligns correctly with the engine’s main journals, reducing friction and wear, and contributing to the longevity and reliability of the engine.

Grouping by Application

While the V28 engine is a notable example, the Main Bearing Cap 180158 is also compatible with other Cummins engines that share similar design principles and engineering requirements. This part is often used in engines that demand high durability and performance, making it a versatile choice for various industrial and commercial applications.

The compatibility of the Main Bearing Cap 180158 with these engines underscores Cummins’ commitment to providing high-quality, reliable components that meet the demanding needs of their customers.

Understanding the Integration of Part 180158 Main Bearing Cap in Engine Systems

The part 180158 Main Bearing Cap is an essential component in the assembly and functionality of various engine systems. Its role is to secure the main bearings in place, which are responsible for supporting the crankshaft and allowing it to rotate smoothly within the engine.

Interaction with Base Parts and Cylinder Block

When integrating the Main Bearing Cap with the base parts and cylinder block, it is important to ensure a precise fit. The cylinder block, which forms the structural core of the engine, houses the cylinders and main bearing journals. The Main Bearing Cap is bolted to the cylinder block, enveloping the main bearings that sit between the cap and the crankshaft. This setup ensures that the crankshaft is held in alignment and can rotate with minimal friction.

Role in Cylinder Block Kit and Short Block Assemblies

In a cylinder block kit, which typically includes the cylinder block, pistons, and other necessary components for a complete engine rebuild, the Main Bearing Cap plays a part in reestablishing the engine’s structural integrity. It is critical during the reassembly phase to align the Main Bearing Cap correctly with the main bearing journals to prevent any misalignment that could lead to engine damage.

For short block assemblies, which include the cylinder block, crankshaft, pistons, and main bearings but exclude ancillary components like the head and intake system, the Main Bearing Cap is indispensable. It ensures that the crankshaft is properly supported and that the rotational forces are evenly distributed across the main bearings.

Specifics for V-12 Engine Blocks

In the case of V-12 engines, whether it’s a cylinder short V-12 block or a full cylinder V-12 block, the Main Bearing Cap’s function remains consistent but is replicated across the engine’s two banks. Each bank of the V-12 engine has its own set of main bearings and corresponding Main Bearing Caps, which must be installed with precision to maintain the engine’s balance and performance.

Importance in Short Block Engine Kit

A short block engine kit, which provides all the necessary components to rebuild the lower end of an engine, relies heavily on the correct installation of the Main Bearing Cap. This kit usually includes the cylinder block, crankshaft, pistons, connecting rods, and main bearings. The Main Bearing Cap is the final piece that secures the main bearings in place, completing the lower end assembly and preparing it for the installation of the upper engine components.

Foundation on the Subbase

Lastly, the subbase, which is the lowermost part of the engine structure, provides the foundation upon which the cylinder block is mounted. The Main Bearing Cap, by securing the main bearings, indirectly contributes to the stability of the engine on the subbase. A secure and well-aligned Main Bearing Cap ensures that the crankshaft’s movement is smooth and that the engine’s overall vibration is minimized, leading to a more stable and efficient operation.

Conclusion

The Cummins 180158 Main Bearing Cap is a vital component in the operation and maintenance of heavy-duty truck engines. Its design and function contribute significantly to the engine’s stability, efficiency, and longevity. Proper installation, maintenance, and troubleshooting are essential for ensuring the optimal performance of this part and, by extension, the engine as a whole.

-

Automotive Lubricants Reference Book, Arthur J Caines, Roger F Haycock and John E Hillier, SAE International, 2004

↩ -

Haynes Diesel Engine Systems and Data Book, Steve Rendle, Martynn Randall, Haynes Publishing, 2000

↩ -

Automotive Transmissions Fundamentals Selection Design and Application, Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Springer Vieweg, 2011

↩ -

How to Rebuild Any Automotive Engine, Barry Kluczyk, CarTech, 2008

↩ -

QSF2.8 CM2880 F104, Service Manual (4332741)

↩ -

Automotive Lubricants Reference Book, Arthur J Caines, Roger F Haycock and John E Hillier, SAE International, 2004

↩ -

Cummins Inc. Overview, Cummins Inc., 2023

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.