This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 2884792 Thrust Bearing is a specialized component designed for use in heavy-duty truck engines. Its purpose is to manage axial loads within the engine, ensuring smooth and efficient operation. The significance of this bearing lies in its ability to enhance the durability and reliability of the engine, contributing to overall performance and longevity 1.

Basic Concepts of Thrust Bearings

Thrust bearings are mechanical components that facilitate the handling of axial loads—forces that act parallel to the axis of rotation. In mechanical systems, these bearings play a role in supporting and stabilizing rotating elements, such as shafts, by counteracting axial forces. This function is vital for maintaining the alignment and integrity of rotating components, thereby ensuring the efficient operation of the system 2.

Purpose of the 2884792 Thrust Bearing

The Cummins 2884792 Thrust Bearing is specifically engineered to manage axial loads within a truck engine. By supporting the crankshaft and other rotating components, it helps to maintain proper alignment and reduce friction. This bearing plays a role in absorbing and distributing axial forces, which are generated during engine operation, thus contributing to the stability and efficiency of the engine 3.

Key Features

The Cummins 2884792 Thrust Bearing boasts several primary features that enhance its performance. These include a robust material composition, typically consisting of high-quality alloys that offer superior strength and durability. The design elements of this bearing are tailored to withstand the rigorous demands of heavy-duty applications, featuring precision-machined surfaces and optimized load distribution. Additionally, unique characteristics such as advanced lubrication systems and anti-friction coatings may be incorporated to further improve its operational efficiency 4.

Benefits

The advantages provided by the Cummins 2884792 Thrust Bearing include improved engine efficiency, durability, and reliability. By effectively managing axial loads, this bearing contributes to reduced wear and tear on engine components, leading to extended service life. Furthermore, its design enhances the overall stability and performance of the engine, resulting in smoother operation and potentially lower maintenance costs over time 1.

Installation Considerations

When installing the Cummins 2884792 Thrust Bearing, it is important to follow guidelines and best practices to ensure proper integration into the engine system. Necessary tools may include precision measuring instruments, torque wrenches, and alignment tools. The installation procedure should involve careful inspection of the bearing and mating surfaces, proper lubrication, and precise torque settings to secure the bearing in place. Precautions such as avoiding contamination and ensuring correct alignment are crucial for the bearing’s optimal performance 2.

Troubleshooting Common Issues

Frequent problems associated with thrust bearings can include excessive wear, noise, and failure to manage axial loads effectively. Diagnosing these issues may involve inspecting the bearing for signs of damage, measuring clearances, and assessing lubrication conditions. Potential solutions can range from re-lubrication and adjustment to replacement of the bearing, depending on the severity of the issue. Regular monitoring and maintenance can help prevent many common problems 3.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 2884792 Thrust Bearing, regular maintenance is recommended. This includes periodic inspection intervals to check for signs of wear or damage, ensuring proper lubrication, and verifying that all components are correctly aligned and secured. Adhering to manufacturer-recommended maintenance schedules and practices will help maintain the bearing’s efficiency and reliability over time 4.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a rich history in the automotive industry, particularly known for producing high-quality engine components. Established with a commitment to innovation and excellence, Cummins has built a reputation for delivering reliable and durable products that meet the demanding requirements of heavy-duty applications. The company’s expertise in engine technology and component manufacturing underscores its position as a leader in the industry 1.

Role of Part 2884792 Thrust Bearing in Engine Systems

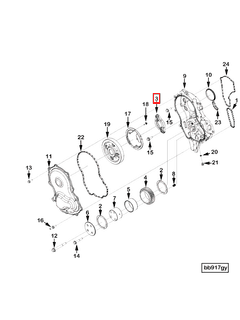

The Part 2884792 Thrust Bearing is an essential component in the efficient operation of various engine systems. It is strategically positioned within the housing to manage axial loads generated by the rotating components.

In the context of the front gear, the Thrust Bearing plays a significant role in maintaining the proper alignment and reducing friction between the gear and the housing. This alignment is vital for the smooth transmission of power from the front gear to other parts of the engine.

The Thrust Bearing absorbs the axial forces that arise due to the gear’s rotation, preventing undue stress on the housing and ensuring that the gear operates within its designed parameters. This not only enhances the durability of the gear but also contributes to the overall stability and performance of the engine system.

By effectively managing these forces, the Thrust Bearing allows for consistent and reliable operation of the engine, facilitating efficient power delivery and minimizing wear on interconnected components 2.

Conclusion

The Cummins 2884792 Thrust Bearing is a critical component in heavy-duty truck engines, designed to manage axial loads and enhance engine durability and reliability. Its robust design, featuring high-quality materials and precision engineering, ensures efficient operation and longevity. Proper installation, regular maintenance, and troubleshooting of common issues are essential for optimal performance. Cummins’ commitment to innovation and excellence in engine component manufacturing underscores the importance of this bearing in ensuring the efficient and reliable operation of heavy-duty engines 1234.

-

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ ↩ ↩ ↩ -

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩ ↩ ↩ ↩ -

Happian-Smith, J. (2002). An Introduction to Modern Vehicle Design. Butterworth-Heinemann.

↩ ↩ ↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.