This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

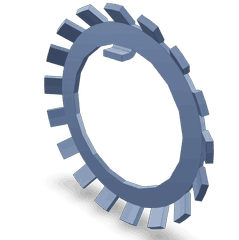

The 2894636 Bearing Lock Washer is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This washer plays a role in the reliable operation of commercial trucks, ensuring the stability and efficiency of various mechanical systems.

Basic Concepts of Bearing Lock Washers

A bearing lock washer is a mechanical component designed to secure bearings in place within a system. It operates by preventing the relative movement between the bearing and the shaft or housing, thereby maintaining the alignment and integrity of the bearing setup. This is achieved through the washer’s design, which often includes features like split sections or serrations that grip the bearing and the adjacent components 1.

Purpose of the 2894636 Bearing Lock Washer

The 2894636 is specifically engineered to enhance the operation of commercial trucks. It is applied in various truck components where bearings are used, such as in the drivetrain, engine components, and wheel assemblies. By securing the bearings, it helps maintain the precise alignment and reduces the risk of wear and failure in these critical areas.

Key Features

The 2894636 boasts several key features that contribute to its performance. It is made from high-quality materials that offer durability and resistance to wear. The design includes specific attributes such as a split configuration or serrated edges, which provide a firm grip on the bearing and the surrounding components. These characteristics ensure that the washer can withstand the demanding conditions encountered in commercial truck operations.

Benefits

The use of the 2894636 offers several benefits. It improves the stability of bearings by preventing unwanted movement, which can lead to premature wear or failure. The enhanced durability of the washer contributes to the overall reliability of the truck, reducing the likelihood of unexpected downtime. Additionally, by maintaining the integrity of the bearing setup, it supports the efficient operation of the truck’s mechanical systems.

Installation Process

Proper installation of the 2894636 is crucial for its effective function. The process involves placing the washer between the bearing and the shaft or housing, ensuring it is correctly aligned and securely in place. Tools such as pliers may be required to properly seat the washer, depending on its specific design features. Following the manufacturer’s guidelines for installation is recommended to ensure optimal performance.

Common Issues and Troubleshooting

Common issues with the 2894636 may include wear and tear over time or improper installation. Signs of wear may manifest as increased noise from the bearing or a noticeable decrease in performance. Troubleshooting these issues often involves inspecting the washer for signs of damage or misalignment and replacing it if necessary. Ensuring correct installation practices can prevent many of these issues.

Maintenance Tips

Regular maintenance of the 2894636 is important for its longevity and performance. This includes periodic inspections for signs of wear or damage, cleaning to remove any debris that may affect its function, and replacement when it shows signs of significant wear. Adhering to recommended maintenance schedules can help prevent unexpected failures and ensure the continued reliability of the truck’s mechanical systems.

Role in Truck Performance

The 2894636 plays a role in the overall performance and efficiency of commercial trucks. By securing bearings in critical components, it contributes to the smooth operation of the engine and drivetrain. This not only enhances the truck’s reliability but also supports its efficiency, as properly aligned and secure bearings reduce friction and wear, leading to better fuel economy and reduced maintenance costs.

About Cummins

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to producing high-quality components. With a rich history and a strong reputation for reliability and innovation, Cummins continues to be a trusted name among professionals in the field. Their dedication to excellence is evident in the design and performance of components like the 2894636.

Compatibility with Cummins Engines

The 2894636, manufactured by Cummins, is a component designed to ensure the stability and longevity of various engine systems. This part is compatible with several Cummins engine models, providing a secure fit and reliable performance across different engine configurations.

ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250 Engines

The 2894636 is specifically engineered to fit seamlessly with the ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250 engines. These engines are known for their robust performance and are widely used in heavy-duty applications. The washer’s design ensures that it maintains the integrity of the bearing assembly, preventing any unwanted movement that could lead to mechanical failure.

ISZ13 CM2150 Z105 and QSZ13 CM2150 Z102 Engines

Similarly, the 2894636 is also compatible with the ISZ13 CM2150 Z105 and QSZ13 CM2150 Z102 engines. These engines are part of Cummins’ lineup of high-efficiency, low-emission power units. The washer’s precision fit is essential for maintaining the alignment and operational efficiency of these engines, ensuring they perform optimally under various conditions.

QSX11.9 CM2250 ECF Engine

The 2894636 also fits the QSX11.9 CM2250 ECF engine. This engine is designed for applications requiring a balance of power and fuel efficiency. The washer’s role in this engine is to secure the bearings, contributing to the overall reliability and durability of the engine.

By ensuring a proper fit and function, the 2894636 plays a vital role in the performance and longevity of these Cummins engines. Its compatibility across multiple engine models highlights its versatility and importance in maintaining engine integrity.

Role in Engine Systems

In the context of engine systems, the 2894636 is instrumental in ensuring the stability and efficiency of various components.

Drive System

Within the drive system, the Bearing Lock Washer secures the bearings in place, preventing any unwanted movement that could lead to misalignment or increased friction. This stability is essential for the smooth transfer of power from the engine to the driven components, ensuring optimal performance and longevity of the drive system.

Rear Gear Train Accessory

In the rear gear train accessory, the Bearing Lock Washer plays a significant role in maintaining the precise alignment of gears. By securing the bearings, it helps in reducing wear and tear on the gear teeth, thus enhancing the efficiency and reliability of the gear train. This is particularly important in high-torque applications where precision and durability are paramount.

Power Take-Off Housing

When integrated into the power take-off (PTO) housing, the Bearing Lock Washer ensures that the bearings remain fixed in their designated positions. This is vital for the PTO system, as it often deals with significant loads and variable speeds. The washer’s role in maintaining bearing stability contributes to the consistent and reliable transfer of power to auxiliary equipment, such as hydraulic pumps or generators.

Conclusion

The 2894636 Bearing Lock Washer is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its role in securing bearings, ensuring alignment, and reducing wear is essential for the reliability and efficiency of these systems. Proper installation, regular maintenance, and understanding its compatibility with various engine models are key to maximizing the benefits of this Cummins part.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.