This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

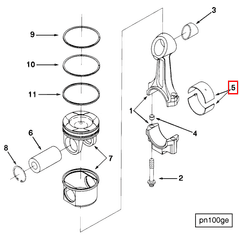

The Cummins 3055147 Connecting Rod Bearing is a component designed for use in commercial truck engines. Its purpose is to facilitate smooth operation between the connecting rod and the crankshaft, ensuring efficient transfer of power. This bearing plays a role in maintaining the overall performance and reliability of truck engines.

Basic Concepts of Connecting Rod Bearings

Connecting rod bearings are components found in internal combustion engines. They function by providing a low-friction interface between the connecting rod and the crankshaft. This allows for the efficient conversion of the linear motion of the piston into rotational motion of the crankshaft. These bearings are typically composed of a steel backing with a thin layer of bearing material that can withstand high loads and temperatures 1.

Role of the 3055147 Connecting Rod Bearing in Truck Operation

The 3055147 Connecting Rod Bearing specifically contributes to the operation of a truck engine by enabling the smooth transfer of motion from the piston to the crankshaft. This bearing reduces friction and wear, which helps in maintaining the engine’s efficiency and longevity. By ensuring a precise fit and smooth operation, it plays a part in the overall performance and reliability of the engine 2.

Key Features of the 3055147 Connecting Rod Bearing

This Cummins part is engineered with specific design and construction features to enhance its performance. It is made from high-quality materials that offer durability and resistance to wear. The bearing includes precise tolerances to ensure a proper fit within the engine assembly. Additionally, it may feature unique characteristics such as enhanced lubrication grooves to improve oil flow and reduce friction 3.

Benefits of Using the 3055147 Connecting Rod Bearing

Utilizing the 3055147 Connecting Rod Bearing provides several advantages. These include improved durability due to its robust construction, reduced friction thanks to its design and material properties, and enhanced performance as a result of its precise engineering. These factors contribute to the overall efficiency and reliability of the engine 4.

Troubleshooting Common Issues with Connecting Rod Bearings

Identifying and addressing common problems with connecting rod bearings is important for maintaining engine health. Symptoms of bearing failure may include unusual noises, increased oil consumption, or decreased engine performance. Diagnostic techniques can involve visual inspection, oil analysis, and performance testing to determine the condition of the bearings.

Maintenance Practices for Connecting Rod Bearings

To ensure optimal performance and longevity of connecting rod bearings, regular maintenance practices should be followed. This includes periodic inspection for signs of wear or damage, adhering to lubrication guidelines to ensure proper oil flow, and replacing bearings at recommended intervals or when signs of failure are detected.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its range of engine and power generation products. With a history of innovation and quality, Cummins has built a reputation for producing reliable and high-performance engines. The company’s product offerings include a variety of engine types and components designed to meet the demanding requirements of commercial applications.

Conclusion

The 3055147 Connecting Rod Bearing is a critical component in the operation of commercial truck engines. Its design and construction features contribute to the efficient and reliable performance of the engine. Regular maintenance and prompt troubleshooting of issues are essential to ensure the longevity and efficiency of this part.

-

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons, 2019.

↩ -

Caines, Arthur J., Haycock, Roger F., & Hillier, John E. Automotive Lubricants Reference Book. SAE International, 2004.

↩ -

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Berns, Karsten, et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.