This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

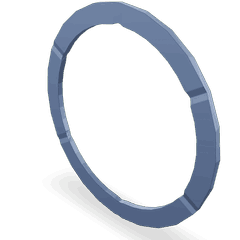

The Cummins 3082121 Thrust Bearing is a specialized component designed for use in heavy-duty truck engines. Its purpose is to manage axial loads generated during engine operation, ensuring smooth and efficient performance. This bearing is significant due to its role in maintaining the integrity and functionality of the engine’s moving parts under various operational conditions 1.

Basic Concepts of Thrust Bearings

Thrust bearings are designed to handle axial loads, which are forces that act parallel to the axis of rotation. In an engine, these forces are generated as the crankshaft rotates and interacts with other components. Thrust bearings play a role in managing these forces by providing a surface for the axial loads to be distributed across, thereby reducing wear and tear on the engine components 2.

Purpose of the 3082121 Thrust Bearing

The Cummins 3082121 Thrust Bearing is specifically engineered to handle the axial forces produced during the operation of a truck engine. It is positioned to absorb these forces, which helps in maintaining the alignment and stability of the crankshaft. By effectively managing these forces, the bearing contributes to the overall efficiency and longevity of the engine 3.

Key Features

The 3082121 Thrust Bearing features a design that includes precision-machined surfaces to ensure optimal contact and load distribution. It is constructed from high-quality materials that offer durability and resistance to wear. Unique characteristics such as enhanced lubrication pathways and robust construction further contribute to its performance and longevity.

Benefits

The use of the 3082121 Thrust Bearing provides several advantages. It contributes to improved engine efficiency by ensuring that axial forces are properly managed, which reduces unnecessary wear on other components. Additionally, it enhances the overall performance of the truck by maintaining the stability and alignment of the crankshaft, leading to smoother operation and potentially extending the engine’s service life.

Installation Considerations

Proper installation of the 3082121 Thrust Bearing is crucial for its effective function. Guidelines recommend ensuring that the engine is clean and free of debris before installation. Special tools may be required to properly seat the bearing and ensure it is aligned correctly within the engine assembly. Following manufacturer specifications for torque and alignment is also important.

Maintenance and Troubleshooting

Routine maintenance of the 3082121 Thrust Bearing involves regular inspections for signs of wear or damage. Lubrication should be checked to ensure it is adequate, as proper lubrication is vital for the bearing’s performance. Common issues may include unusual noises or vibrations, which could indicate problems with the bearing. Troubleshooting steps may involve inspecting the bearing for damage, ensuring proper lubrication, and checking for correct installation.

Performance in Various Conditions

The 3082121 Thrust Bearing is designed to perform under a range of operating conditions. It can handle heavy loads, extreme temperatures, and varying speeds, making it suitable for the demanding environments typical of heavy-duty truck engines. Its robust design and high-quality materials ensure reliable performance across these varied conditions.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a long history of producing diesel engines and related components. The company is known for its commitment to quality and innovation, providing reliable and efficient solutions for a wide range of industries. Cummins’ reputation is built on its expertise in engine technology and its dedication to customer satisfaction.

Cummins Thrust Bearing 3082121 Compatibility

The Cummins thrust bearing part number 3082121 is designed to be compatible with a range of Cummins engines, ensuring reliable performance and durability across various applications. Below is a detailed overview of the engines with which this thrust bearing is compatible.

QSK45 and QSK60 Series

The thrust bearing 3082121 fits seamlessly with the QSK45 CM500 and QSK60 CM500 engines. These engines are part of the Cummins QSK series, known for their robust design and efficiency. The thrust bearing plays a role in these engines by maintaining the alignment of the crankshaft, reducing friction, and ensuring smooth operation.

QSK60 Series with Higher Power Ratings

For the QSK60 CM850 MCRS and QSK60 G CM2358 K110 engines, the thrust bearing 3082121 is equally essential. These engines, with their higher power ratings, require a bearing that can handle increased loads and stresses. The compatibility of this thrust bearing with these models ensures that the engines can operate at peak performance without compromising on reliability.

QSK60G Series

The QSK60G engines also benefit from the use of the thrust bearing 3082121. This series is designed for high-performance applications, and the thrust bearing’s role in maintaining crankshaft alignment and reducing friction is critical to the engine’s efficiency and longevity.

QSK78 Series

The QSK78 CM500 engine is another model that is compatible with the thrust bearing 3082121. This engine is part of the Cummins QSK series, which is known for its versatility and reliability in various industrial applications. The thrust bearing ensures that the engine operates smoothly and efficiently.

QSK95 Series

Lastly, the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines also utilize the thrust bearing 3082121. These engines are designed for heavy-duty applications, and the thrust bearing’s ability to handle high loads and stresses is essential for maintaining engine performance and reliability.

Role of Part 3082121 Thrust Bearing in Engine Systems

The Part 3082121 Thrust Bearing is an essential component in the efficient operation of various engine systems. It is specifically designed to handle axial loads that occur along the axis of rotation, which are common in high-performance and high-load engine environments.

Interaction with the Block and Cylinder

Within the engine block, the thrust bearing works in conjunction with the cylinder to manage the axial forces generated during combustion. As the pistons move up and down within the cylinders, they create forces that push against the crankshaft. The thrust bearing absorbs these forces, ensuring that the crankshaft remains stable and aligned within the engine block.

Integration with Crankshaft and Bearings

The crankshaft, a pivotal component in converting linear motion into rotational motion, relies heavily on the thrust bearing for smooth operation. The thrust bearing is typically located at the front or rear of the crankshaft, depending on the engine design. It supports the crankshaft by mitigating the end play, which is the slight movement that can occur due to thermal expansion and contraction. This support is vital for maintaining the precision alignment of the crankshaft journals within their respective main bearings.

Design and Alternative Considerations

In engine design, the thrust bearing is often part of a bearing set that includes main bearings and rod bearings. Engineers may consider alternative bearing materials or designs based on the specific requirements of the engine, such as higher load capacities or reduced friction. The thrust bearing’s design must complement these alternatives to ensure overall engine reliability and performance.

Drive and Accessory Drive Systems

The thrust bearing also plays a role in the drive and accessory drive systems. For instance, in engines where the front gear is connected to the crankshaft, the thrust bearing helps in maintaining the gear’s position and reducing wear. This is particularly important in systems where the front gear drives accessories like the fuel pump or hydraulic pump.

Fuel Pump and Gear Housing

In engines where the fuel pump is driven by the front gear, the thrust bearing ensures that the gear housing remains stable. This stability is essential for the consistent operation of the fuel pump, which relies on precise timing and pressure to deliver fuel to the combustion chambers.

Hydraulic Pump Drive and Water Pump

Similarly, in engines equipped with a hydraulic pump drive, the thrust bearing assists in keeping the hydraulic pump’s drive gear aligned and operational. Additionally, in engines where the water pump is driven by the front gear, the thrust bearing contributes to the efficient circulation of coolant, which is vital for maintaining optimal engine temperature.

Housing and Front Gear

The housing that encloses these components also benefits from the presence of the thrust bearing. By stabilizing the front gear and other rotating elements, the thrust bearing helps in reducing the stress on the housing, thereby prolonging its lifespan and ensuring a secure fit for all internal components.

Conclusion

The Cummins 3082121 Thrust Bearing is a versatile and reliable component that fits a wide range of Cummins engines, from the QSK45 and QSK60 series to the higher-rated QSK60 and QSK95 models. Its compatibility with these engines ensures that they can operate efficiently and reliably in various demanding applications. The thrust bearing’s role in managing axial loads and ensuring the stability of critical components like the crankshaft, front gear, and various drive systems is integral to the engine’s performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.