This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Thrust Bearing Wear Plate 3420590, manufactured by Cummins, is a critical component in the commercial truck industry. This part is essential for the efficient and durable operation of heavy-duty truck engines. Understanding its function and importance can offer valuable insights into engine maintenance and performance optimization.

Basic Concepts of Thrust Bearing Wear Plates

Thrust bearings are engineered to handle axial loads within an engine, which occur along the axis of rotation. Wear plates, like the Thrust Bearing Wear Plate 3420590, are installed to safeguard these bearings from excessive wear and damage. They interact closely with the crankshaft and other engine components, ensuring smooth operation and longevity of the engine 1.

Role of the Thrust Bearing Wear Plate in Truck Operation

The Thrust Bearing Wear Plate 3420590 is pivotal in the operation of heavy-duty trucks. It provides a durable surface that reduces friction between the thrust bearing and the crankshaft. This interaction is vital for maintaining the precision and efficiency of the engine’s rotational movement. The wear plate aids in distributing loads evenly, which is essential for consistent engine performance under various operating conditions 2.

Key Features of the Thrust Bearing Wear Plate 3420590

The design and material characteristics of the Thrust Bearing Wear Plate 3420590 contribute to its effectiveness. Constructed from high-quality materials, it offers superior durability and resistance to wear. Its design ensures seamless integration with Cummins engines, enhancing their performance and reliability. The wear plate’s construction is tailored to withstand the high stresses and temperatures encountered in heavy-duty truck engines 3.

Benefits of Using the Thrust Bearing Wear Plate 3420590

Incorporating the Thrust Bearing Wear Plate 3420590 into heavy-duty truck engines offers several advantages. It enhances engine performance by ensuring smooth operation of the thrust bearing. The wear plate’s durability contributes to the engine’s longevity, reducing the need for frequent replacements. Additionally, its reliable performance under demanding conditions supports the overall reliability of the engine.

Troubleshooting and Maintenance Suggestions

Identifying common issues related to the Thrust Bearing Wear Plate 3420590 can help in maintaining optimal engine performance. Regular inspections for signs of wear or damage are recommended. Maintenance practices should include checking the alignment and condition of the wear plate, ensuring it remains in good condition. Following manufacturer guidelines for maintenance can help in preventing issues and ensuring the longevity of the component.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history and a diverse product range, Cummins has established a strong reputation for producing reliable and high-performance engines. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a trusted provider in the industry.

Cummins Thrust Bearing Wear Plate 3420590 Compatibility

The Cummins Thrust Bearing Wear Plate, part number 3420590, is designed to fit seamlessly with a variety of engine models. This wear plate is integral to the performance and longevity of the engine, providing a protective layer that reduces wear and tear on the thrust bearing.

Engine Compatibility

-

QSV91G, QSW/QSV82, QSW27, QSW36, QSW73

- The thrust bearing wear plate 3420590 is compatible with these engines, ensuring optimal performance and durability. This part is engineered to meet the specific requirements of these engine models, providing a reliable solution for maintaining the integrity of the thrust bearing system.

-

QSW27 and QSW36

- These engines benefit from the use of the 3420590 thrust bearing wear plate, which is designed to fit precisely within their thrust bearing assemblies. This ensures that the engines operate smoothly and efficiently, minimizing the risk of premature wear and extending the lifespan of the thrust bearing components.

-

QSV91G and QSW/QSV82

- For these engines, the 3420590 thrust bearing wear plate is a critical component that enhances the overall performance and reliability of the engine. Its precise fit and high-quality construction make it an essential part for maintaining the health of the thrust bearing system.

By ensuring compatibility with these engine models, the Cummins Thrust Bearing Wear Plate 3420590 provides a reliable and effective solution for engine maintenance and repair.

Role of Part 3420590 Thrust Bearing Wear Plate in Engine Systems

The Thrust Bearing Wear Plate, identified as part 3420590, is an integral component in the efficient operation of various engine systems. It is specifically designed to interface with the engine assembly piston, providing a durable surface that mitigates wear and tear on the thrust bearing. This interaction is vital for maintaining the precision and reliability of the piston’s movement within the engine cylinder.

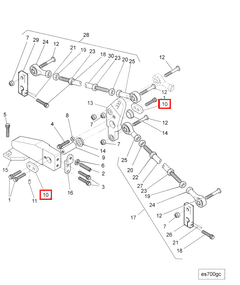

In the context of the governor assembly linkage and the governor counter assembly linkage, the Thrust Bearing Wear Plate ensures smooth operation by reducing friction between moving parts. This is particularly important in systems where the governor linkage and control linkage lever are in constant motion, as it helps in preserving the integrity of these components over time.

Furthermore, the Thrust Bearing Wear Plate plays a supportive role in the governor control system. By offering a stable and wear-resistant surface, it contributes to the accurate modulation of engine speed and power output, which is essential for the efficient performance of the engine.

In engines equipped with piston cooling assembly nozzles, the Thrust Bearing Wear Plate aids in maintaining the optimal temperature of the piston. This is achieved by ensuring that the piston’s movement is consistent and unimpeded, allowing for effective cooling and lubrication.

Additionally, in systems utilizing prechamber bits and QSVS (Quick Start Variable Geometry) technology, the Thrust Bearing Wear Plate’s role becomes even more significant. It ensures that the complex interactions between the piston, engine, and various linkages are smooth and efficient, contributing to the overall performance and longevity of the engine.

In D67 engines, where precision and durability are paramount, the Thrust Bearing Wear Plate is a key component in maintaining the engine’s operational integrity. Its ability to withstand high levels of stress and wear makes it an essential part of the engine’s design, ensuring that all interconnected components function harmoniously.

Conclusion

The Thrust Bearing Wear Plate 3420590 by Cummins is a vital component in the maintenance and performance of heavy-duty truck engines. Its role in reducing friction, distributing loads evenly, and protecting thrust bearings from wear and damage is crucial for the efficient and reliable operation of these engines. Regular maintenance and adherence to manufacturer guidelines are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.