This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

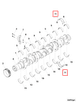

The Cummins 3639306 Thrust Bearing is a specialized component designed for use in heavy-duty truck engines. Its primary function is to manage axial loads generated during engine operation, ensuring smooth and efficient performance. The significance of this bearing in the engine’s operation cannot be overstated, as it contributes to the overall reliability and durability of the engine 1.

Basic Concepts of Thrust Bearings

Thrust bearings are mechanical components that facilitate the management of axial loads within an engine. These loads are generated by the rotational motion of the crankshaft and other moving parts, which can create forces that push along the axis of rotation. Thrust bearings are designed to absorb these axial forces, preventing damage to the engine and ensuring that components remain properly aligned. By managing these forces, thrust bearings play a vital role in maintaining the integrity and performance of the engine 2.

Purpose of the 3639306 Thrust Bearing

The Cummins 3639306 Thrust Bearing is specifically engineered to handle the axial forces produced during the operation of a truck engine. It is positioned to absorb these forces, which helps in maintaining the proper alignment of the crankshaft and other rotating components. By effectively managing these axial loads, the bearing contributes to the smooth operation of the engine, reducing wear and tear on critical components and enhancing overall engine efficiency 3.

Key Features

The Cummins 3639306 Thrust Bearing boasts several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to wear and capable of withstanding the high loads and temperatures encountered in heavy-duty truck engines. The bearing’s construction includes precision-machined surfaces to ensure optimal contact and minimal friction, which contributes to its longevity and reliability. Additionally, the bearing is engineered to provide consistent performance under varying operating conditions, making it a robust choice for demanding applications 4.

Benefits

The advantages provided by the Cummins 3639306 Thrust Bearing are numerous. By effectively managing axial loads, it contributes to improved engine efficiency and reduced wear on engine components. This results in enhanced longevity for the engine, as critical parts are less likely to experience premature failure. Additionally, the bearing’s design helps to maintain proper alignment of the crankshaft, which is essential for smooth engine operation and overall performance 5.

Installation and Integration

Installing the Cummins 3639306 Thrust Bearing in a truck engine requires careful attention to detail to ensure proper integration and performance. The installation process should begin with a thorough inspection of the engine components to ensure they are clean and free from debris. The bearing should be positioned according to the manufacturer’s specifications, with attention paid to alignment and clearances. It is also important to follow any specific requirements or precautions outlined by Cummins to ensure the bearing operates effectively within the engine .

Troubleshooting Common Issues

Common problems associated with thrust bearings can include excessive wear, noise, or failure to manage axial loads effectively. These issues may arise from improper installation, misalignment, or the use of incompatible components. To address these problems, it is important to conduct a thorough inspection of the bearing and surrounding components. This may involve checking for proper alignment, ensuring that clearances are within specifications, and verifying that the bearing is compatible with the engine’s design. In some cases, it may be necessary to replace the bearing or other components to restore optimal performance .

Maintenance Practices

To ensure the Cummins 3639306 Thrust Bearing operates at peak performance, regular maintenance is essential. This includes periodic inspections to check for signs of wear, such as scoring or pitting on the bearing surfaces. Lubrication is also critical, as it helps to reduce friction and wear. The type and frequency of lubrication should be in accordance with the manufacturer’s recommendations. Additionally, monitoring the bearing for any unusual noises or vibrations can help identify potential issues before they lead to more significant problems .

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for producing high-quality engine components, including the 3639306 Thrust Bearing. The company’s commitment to innovation, quality, and customer satisfaction has made it a trusted name in the automotive industry, particularly for heavy-duty truck applications. Cummins’ extensive product range and dedication to excellence ensure that their components, like the 3639306 Thrust Bearing, meet the demanding requirements of modern engines .

Conclusion

The Cummins 3639306 Thrust Bearing is a critical component in heavy-duty truck engines, designed to manage axial loads and ensure smooth, efficient operation. Its high-quality materials, precision-machined surfaces, and robust design contribute to the engine’s reliability and durability. Proper installation, regular maintenance, and timely troubleshooting are essential to maximize the performance and longevity of this Cummins part.

-

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 4021433-01, Master Repair Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.