This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

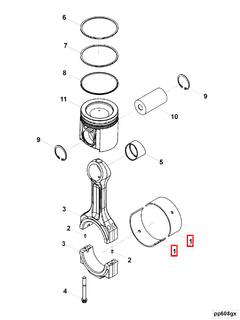

The Cummins 3647654 Connecting Rod Bearing is a critical component designed to facilitate the smooth operation of heavy-duty truck engines. Its primary function is to reduce friction between the connecting rod and the crankshaft, ensuring efficient power transmission and engine performance. The significance of this bearing lies in its ability to enhance the durability and reliability of the engine, contributing to the overall efficiency and longevity of the truck 1.

Basic Concepts of Connecting Rod Bearings

Connecting rod bearings are integral components within an engine, positioned between the connecting rod and the crankshaft. Their primary function is to minimize friction and wear, allowing for smooth rotational movement. These bearings play a role in maintaining the engine’s performance and durability by ensuring that the connecting rod can move freely without excessive resistance 3. Proper functioning of connecting rod bearings is vital for the engine’s efficiency and longevity.

Role of the 3647654 Connecting Rod Bearing in Truck Operation

The Cummins 3647654 Connecting Rod Bearing specifically facilitates the connection between the crankshaft and the piston in a truck engine. By reducing friction at this critical junction, it allows for smoother and more efficient power transmission from the piston to the crankshaft. This bearing ensures that the engine operates with minimal resistance, contributing to the truck’s overall performance and fuel efficiency 2.

Key Features of the 3647654 Connecting Rod Bearing

The Cummins 3647654 Connecting Rod Bearing is characterized by its high-quality material composition and precise design. Crafted from durable materials, it is engineered to withstand the high pressures and temperatures within the engine. Its design includes features that enhance lubrication and reduce wear, contributing to its performance and longevity. These characteristics make it a reliable component for heavy-duty applications 3.

Benefits of Using the 3647654 Connecting Rod Bearing

Utilizing the Cummins 3647654 Connecting Rod Bearing offers several advantages. It contributes to improved engine efficiency by reducing friction between the connecting rod and the crankshaft. This reduction in friction leads to less energy loss, enhancing the engine’s overall performance. Additionally, the bearing’s design and material composition contribute to its durability, ensuring long-term reliability and reducing the need for frequent replacements 2.

Troubleshooting Common Issues with Connecting Rod Bearings

Common issues with connecting rod bearings may include excessive wear, unusual noise, or failure. Identifying these problems early can prevent more severe engine damage. Solutions may involve inspecting the bearing for signs of wear, ensuring proper lubrication, and, if necessary, replacing the bearing to restore engine performance. Regular maintenance and attention to these components can help avoid significant repairs 3.

Maintenance Tips for Connecting Rod Bearings

To ensure the longevity and optimal performance of connecting rod bearings, regular maintenance is crucial. This includes inspecting the bearings for signs of wear or damage, ensuring they are properly lubricated, and following recommended replacement schedules. Adhering to these maintenance practices can help prevent issues and ensure the engine operates efficiently 3.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and power generation equipment, Cummins has established a reputation for reliability and performance. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the industry 2.

Cummins Connecting Rod Bearing 3647654 Compatibility

The Cummins Connecting Rod Bearing part number 3647654 is designed to fit seamlessly within several engine models, ensuring optimal performance and longevity. This part is integral to the smooth operation of the engines by reducing friction between the connecting rod and crankshaft.

QSK60 G and QSK60G

The QSK60 G and QSK60G engines are part of Cummins’ QSK series, known for their reliability and efficiency. The 3647654 bearing is specifically engineered to fit these engines, providing a critical interface that ensures the connecting rod moves smoothly over the crankshaft. This compatibility is crucial for maintaining the engine’s operational integrity and preventing wear and tear 2.

CM2358

The CM2358 engine is another model where the 3647654 bearing is applicable. This engine is designed for heavy-duty applications, and the bearing’s precision fit is essential for handling the high loads and stresses encountered in such environments. The 3647654 ensures that the engine operates efficiently and reliably, even under demanding conditions 2.

K110

The K110 engine also benefits from the use of the 3647654 connecting rod bearing. This engine is typically used in various industrial and marine applications, where durability and performance are paramount. The bearing’s design allows for minimal friction and maximum load-bearing capacity, contributing to the engine’s overall efficiency and longevity 2.

Each of these engines relies on the 3647654 bearing to maintain a critical balance between performance and durability. The precision engineering of this part ensures that it fits perfectly within the engine’s design specifications, providing a reliable and efficient operation across various applications.

Role of Part 3647654 Connecting Rod Bearing in Engine Systems

The part 3647654 Connecting Rod Bearing is integral to the smooth operation of several key engine components. It facilitates the efficient transfer of power from the engine piston to the crankshaft, ensuring that the rotational motion required for vehicle propulsion is maintained.

Interaction with the Connecting Rod and Piston

The connecting rod bearing sits between the connecting rod and the crankshaft journal. As the engine piston moves up and down within the cylinder, the connecting rod translates this linear motion into rotational motion via the crankshaft. The bearing allows for minimal friction and smooth operation, which is essential for the longevity and performance of the engine 3.

Contribution to Camshaft Functionality

While the camshaft operates independently of the connecting rod bearing, the overall efficiency of the camshaft is influenced by the engine’s smooth operation. A well-functioning connecting rod bearing ensures consistent engine performance, which in turn allows the camshaft to operate within optimal parameters, timing the opening and closing of the engine’s valves accurately 3.

Impact on Cylinder Head and Engine Performance

The cylinder head houses the valves and interacts closely with the piston during the combustion process. A smoothly operating connecting rod bearing contributes to the engine’s balanced operation, reducing vibrations and enhancing the overall performance. This stability is vital for maintaining the integrity of the cylinder head and ensuring that the combustion process is efficient and reliable 3.

Ensuring Parts Longevity and Engine Performance

The use of high-quality connecting rod bearings like part 3647654 is a testament to the importance of precision engineering in maintaining engine performance. By reducing friction and wear, these bearings play a significant role in the durability of engine parts and the sustained performance of the engine as a whole 3.

Conclusion

The Cummins 3647654 Connecting Rod Bearing is a vital component in the operation of heavy-duty truck engines. Its role in reducing friction and ensuring smooth power transmission contributes significantly to the engine’s efficiency, durability, and overall performance. Regular maintenance and proper use of this bearing are essential for the longevity of the engine and the truck it powers.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Berns, Karsten, et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩ ↩ ↩ ↩ ↩ ↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.