This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3649566 Bearing Assembly Tube, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This part plays a significant role in the mechanical systems of these vehicles.

Basic Concepts of Bearing Assembly Tubes

A bearing assembly tube is a component used in mechanical systems to support rotating elements, reducing friction and enabling smooth operation 1. In the context of heavy-duty trucks, these tubes are integral to the functioning of various systems, ensuring that parts move efficiently and with minimal wear. They contribute to the overall performance and longevity of the truck by maintaining the integrity of rotating assemblies.

Purpose of the 3649566 Bearing Assembly Tube

The 3649566 Bearing Assembly Tube is specifically designed to support and align rotating components within a truck’s mechanical system. Its role is to facilitate the smooth operation of these components, ensuring that they function as intended under the demanding conditions typical of commercial truck use. This tube is part of the system that allows for the efficient transfer of power and motion, contributing to the truck’s operational effectiveness.

Key Features

The 3649566 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design incorporates precise engineering to guarantee optimal alignment and support for rotating components. Additionally, it may include unique attributes such as specialized coatings or treatments that further improve its functionality in harsh operating environments.

Benefits

The advantages of using the 3649566 include improved efficiency and reliability in truck operations. By reducing friction and wear on rotating components, it contributes to smoother operation and potentially extends the lifespan of these parts. For fleet operators, this can translate into cost savings through reduced maintenance needs and enhanced vehicle uptime.

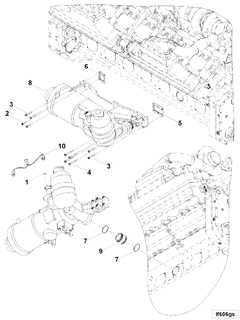

Installation Process

Proper installation of the 3649566 is crucial for its effective performance. The process involves several steps, including preparing the installation site, aligning the tube with the rotating components, and securing it in place. It is important to follow manufacturer guidelines to ensure that the tube is installed correctly, taking into account factors such as torque specifications and alignment requirements.

Maintenance and Care

Regular maintenance and care of the 3649566 are necessary to ensure its continued performance. This includes routine inspections for signs of wear or damage, cleaning to remove contaminants that could affect operation, and applying lubrication as recommended by the manufacturer. Proper maintenance helps to prevent issues that could lead to decreased efficiency or failure of the component.

Troubleshooting Common Issues

Common problems associated with the 3649566 may include misalignment, wear, or contamination. Troubleshooting these issues involves identifying the symptoms, such as unusual noise or vibration, and addressing the root cause. Solutions may range from realigning the tube to replacing worn components or cleaning the area to remove contaminants.

Performance Enhancements

There are potential upgrades or modifications that can be made to the 3649566 to enhance its performance or compatibility with other truck components. These may include using higher-grade materials, applying specialized coatings, or modifying the design to better suit specific operating conditions. Such enhancements can lead to improved efficiency, durability, or compatibility within the truck’s mechanical system.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products that include engines, powertrains, and components. The company has a long history of innovation and quality, establishing a reputation for reliability and performance. This background provides context for the quality and dependability of the 3649566, reflecting Cummins’ commitment to excellence in the industry.

Bearing Assembly Tube (Part 3649566) Compatibility with Cummins Engines

The Bearing Assembly Tube, identified by the part number 3649566, is a critical component designed to fit seamlessly within specific Cummins engine models. This part is integral to the smooth operation and longevity of the engine, ensuring that the moving parts operate with minimal friction and wear.

QSK45 CM500 and QSK60 CM500

The Bearing Assembly Tube (3649566) is compatible with the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust design and high performance. The tube is engineered to fit precisely within these engines, providing essential support and alignment for the crankshaft and other rotating components. Its design ensures that the engine operates efficiently, maintaining optimal performance and reliability.

QSK60 CM850 MCRS

The Bearing Assembly Tube (3649566) also fits the QSK60 CM850 MCRS engine. This model is an advanced iteration of the QSK60 series, incorporating additional features such as the MCRS (Modular Common Rail System). The tube’s design is tailored to accommodate the specific requirements of this engine, ensuring that it can handle the increased demands of the MCRS system. Its precision engineering guarantees that the engine’s components remain properly aligned and supported, contributing to the overall durability and efficiency of the engine.

Each of these engines benefits from the Bearing Assembly Tube’s ability to reduce friction and wear, enhancing the engine’s operational lifespan and performance. The compatibility of this part across these models underscores its versatility and importance in maintaining the integrity of Cummins’ engine designs.

Role of Part 3649566 Bearing Assembly Tube in Engine Systems

The Part 3649566 Bearing Assembly Tube is integral to the efficient operation of several key components within engine systems. Its primary function is to facilitate the smooth transfer of lubricating oil, ensuring that all moving parts within the engine receive adequate lubrication.

Interaction with Filters

In conjunction with the full flow oil filter, the Bearing Assembly Tube plays a significant role in maintaining the cleanliness of the lubricating oil. The full flow oil filter is designed to capture contaminants and debris that could otherwise cause wear and damage to engine components. The Bearing Assembly Tube ensures a consistent flow of oil to the filter, allowing for effective filtration and prolonging the life of the engine.

Lubricating Oil System

The lubricating oil system relies heavily on the Bearing Assembly Tube to distribute oil to various engine parts. The lubricating oil filter head, which is often connected to the Bearing Assembly Tube, works in tandem to regulate the flow and pressure of the oil. This ensures that the oil reaches critical components such as the crankshaft, camshaft, and pistons, reducing friction and heat.

Enhanced Performance

By ensuring a reliable supply of clean, pressurized lubricating oil, the Bearing Assembly Tube contributes to the overall performance and durability of the engine. It helps in maintaining optimal operating temperatures and reduces the risk of premature wear, thereby enhancing the engine’s efficiency and longevity.

Conclusion

The 3649566 Bearing Assembly Tube is a vital component in the mechanical systems of heavy-duty trucks, particularly those equipped with Cummins engines. Its role in supporting and aligning rotating components, facilitating the smooth transfer of lubricating oil, and ensuring the efficient operation of engine systems cannot be overstated. The part’s compatibility with specific Cummins engine models, such as the QSK45 CM500, QSK60 CM500, and QSK60 CM850 MCRS, highlights its versatility and importance in maintaining engine performance and longevity. Proper installation, maintenance, and care of this part are essential to ensure its continued effectiveness and the overall reliability of the truck’s mechanical system.

-

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.