This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

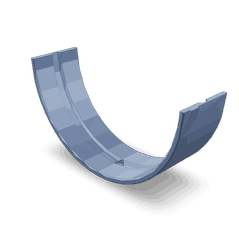

The Cummins 3650920 Main Bearing is a component designed for use in commercial trucks, specifically within Cummins engines. Its purpose is to facilitate the smooth operation of the engine by supporting the crankshaft. The significance of this bearing lies in its ability to reduce friction between moving parts, thereby contributing to the engine’s efficiency and longevity 1.

Basic Concepts of Main Bearings

Main bearings are integral components in an engine, serving to support the crankshaft and allow it to rotate with minimal friction. These bearings are positioned between the crankshaft and the engine block, playing a role in maintaining the crankshaft’s alignment and absorbing the forces generated during engine operation. The performance and longevity of an engine can be significantly influenced by the quality and condition of its main bearings 2.

Role of the 3650920 Main Bearing in Truck Operation

The Cummins 3650920 Main Bearing supports the crankshaft within the engine, enabling it to rotate smoothly. This bearing is engineered to handle the high loads and speeds associated with commercial truck engines, ensuring that the crankshaft operates efficiently. By minimizing friction, the 3650920 Main Bearing contributes to the overall performance and reliability of the truck’s engine 3.

Key Features of the 3650920 Main Bearing

The Cummins 3650920 Main Bearing is characterized by its precision engineering and high-quality materials. It is constructed to exacting standards to ensure optimal performance under the demanding conditions of commercial truck operation. Features such as its durable construction and precise fit within the engine block enhance its ability to support the crankshaft and reduce wear over time 4.

Benefits of Using the 3650920 Main Bearing

Utilizing the Cummins 3650920 Main Bearing offers several advantages. These include improved engine efficiency due to reduced friction, enhanced durability under high-stress conditions, and potential cost savings for fleet operators through extended engine life and reduced maintenance requirements. The bearing’s design also contributes to smoother engine operation, which can lead to better overall truck performance 5.

Installation and Maintenance Guidelines

Proper installation of the Cummins 3650920 Main Bearing involves following specific torque specifications and ensuring precise alignment within the engine block. It is important to adhere to manufacturer guidelines to ensure the bearing is correctly positioned and secured. Regular maintenance, including inspections for wear and proper lubrication, is crucial for ensuring the longevity and optimal performance of the bearing 6.

Troubleshooting Common Issues

Common issues associated with main bearings include noise, excessive wear, and failure symptoms such as metal particles in the oil. Diagnostic methods for identifying these problems may involve visual inspections, oil analysis, and engine performance tests. Addressing these issues promptly can prevent further damage to the engine and ensure continued reliable operation 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to engineering excellence is evident in its range of engine components, including the Cummins 3650920 Main Bearing, which is designed to meet the rigorous demands of commercial truck applications 8.

Conclusion

The Cummins 3650920 Main Bearing is a vital component in the operation of Cummins engines, particularly in commercial trucks. Its role in reducing friction, supporting the crankshaft, and contributing to engine efficiency and longevity cannot be overstated. Proper installation, maintenance, and prompt troubleshooting of issues are essential for maximizing the benefits of this part.

-

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Mollenhauer, Klaus, and Helmut Tschoeke. Handbook of Diesel Engines. Springer, 2010.

↩ -

Bonnick, Allan. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Bonnick, Allan. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩ -

Mollenhauer, Klaus, and Helmut Tschoeke. Handbook of Diesel Engines. Springer, 2010.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.