This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Main Bearing (.030) Set, identified by part number 3802143, is designed for use in heavy-duty truck engines. This part supports the crankshaft within the engine block, ensuring smooth and efficient operation. Engineered to withstand the rigorous demands of heavy-duty applications, this Cummins part contributes to the overall reliability and performance of the engine 1.

Function and Operation

The Main Bearing (.030) Set operates by providing a low-friction interface between the crankshaft and the engine block. These bearings support the crankshaft’s weight and the forces generated during engine operation. By facilitating smooth rotation, they help maintain the crankshaft’s alignment and reduce wear on both the crankshaft and the engine block. The precise clearance of .030 inches allows for optimal oil flow, which is essential for lubrication and cooling of the crankshaft journal 2.

Key Features

The Main Bearing (.030) Set is characterized by several key features that enhance its performance and durability. These include a precise clearance of .030 inches, which ensures proper fit and function within the engine. The material composition typically involves a combination of steel backing and a bearing overlay, which provides both strength and a low-friction surface. The design specifications of these bearings are tailored to meet the specific requirements of Cummins engines, ensuring compatibility and optimal performance 3.

Benefits

The use of the Main Bearing (.030) Set offers several benefits. Improved engine performance is achieved through reduced friction, which allows for smoother crankshaft rotation and more efficient power transmission. The precise clearance and high-quality materials contribute to enhanced durability, helping the engine withstand the stresses of heavy-duty operation. Additionally, the design of these bearings supports better lubrication, which is vital for maintaining the health and longevity of the engine components 1.

Installation Process

Proper installation of the Main Bearing (.030) Set is essential for ensuring the engine’s performance and longevity. The process involves several steps: First, the engine block and crankshaft must be thoroughly cleaned to remove any debris or old bearing material. Next, the new bearings are carefully placed into the main bearing journals of the engine block. It is important to ensure that the bearings are correctly aligned and seated to avoid any damage during engine operation. Finally, the crankshaft is installed, and the engine is reassembled following the manufacturer’s guidelines to ensure all components are properly torqued and aligned 2.

Maintenance and Troubleshooting

Regular maintenance of the Main Bearing (.030) Set is important for prolonging its lifespan and ensuring optimal engine performance. This includes regular inspection for signs of wear or damage, ensuring proper lubrication, and addressing any issues promptly. Common troubleshooting steps involve checking for proper oil pressure and flow, as inadequate lubrication can lead to premature bearing failure. Additionally, any unusual noises or vibrations from the engine may indicate bearing issues and should be investigated 3.

Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related components. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industries. The company’s commitment to excellence is reflected in its product offerings, which are designed to meet the demanding requirements of various applications 1.

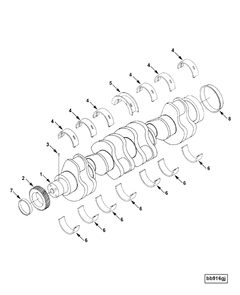

Components of Cummins Kit 3802143 Main Bearing (.030) Set

Main Bearings

The main bearings are the core components of the kit. These bearings are precision-engineered to fit snugly within the crankshaft journals, ensuring smooth rotation and minimizing friction. The .030 designation indicates that these bearings have a specific clearance, which is crucial for maintaining proper oil film thickness and preventing metal-to-metal contact 2.

Bearing Caps

Bearing caps are paired with the main bearings to create a complete bearing assembly. These caps are machined to match the crankshaft journals and are secured with bolts. They play a vital role in maintaining the alignment and integrity of the bearing surfaces 3.

Thrust Washers

Thrust washers are included to control the end play of the crankshaft. These washers are positioned at the front and rear main bearings and help to prevent excessive movement of the crankshaft along its axis, ensuring stability and longevity of the engine components 1.

Dowel Pins

Dowel pins are used to align the bearing caps correctly during installation. These pins ensure that the caps are positioned accurately relative to the crankshaft journals, which is essential for maintaining proper clearances and preventing misalignment 2.

Gaskets

Gaskets are provided to seal the bearing caps to the engine block. These gaskets are critical for preventing oil leaks and maintaining the integrity of the lubrication system. They ensure that oil pressure is maintained within the bearing surfaces, contributing to the overall efficiency and reliability of the engine 3.

Instructions

Detailed instructions are included to guide the user through the installation process. These instructions provide step-by-step guidance on how to properly install each component, ensuring that the main bearing set is installed correctly and functions as intended 1.

Lubricants

Specific lubricants may be included to ensure that the bearings are properly lubricated during installation and initial operation. These lubricants are designed to reduce friction and wear, contributing to the longevity and performance of the main bearing set 2.

Conclusion

The Cummins Main Bearing (.030) Set, part number 3802143, is a critical component for heavy-duty truck engines, designed to ensure smooth and efficient operation. Its precise clearance, high-quality materials, and tailored design specifications contribute to enhanced engine performance and durability. Proper installation, regular maintenance, and prompt troubleshooting are essential for maximizing the lifespan and reliability of this part. Cummins Inc.’s commitment to quality and innovation is evident in the design and functionality of this bearing set, making it a valuable component for any heavy-duty engine application 3.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.