This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3915765 Needle Bearing is a specialized component designed for use in commercial trucks. Its primary function is to facilitate smooth rotational movement within various truck components, thereby enhancing the overall efficiency and reliability of the vehicle. This bearing is integral to the operation of trucks, particularly in applications where high loads and speeds are encountered.

Basic Concepts of Needle Bearings

Needle bearings are a type of rolling-element bearing that utilize elongated, cylindrical rollers resembling needles. These bearings are designed to support both radial and axial loads, making them suitable for applications where space is limited but high load capacity is required. In mechanical systems, needle bearings reduce friction between moving parts, allowing for smoother operation and increased efficiency 1.

Purpose of the Cummins 3915765 Needle Bearing

The Cummins 3915765 Needle Bearing plays a role in the operation of a truck by supporting rotating components under load. It is commonly used in applications such as the transmission, differential, and various engine components. By providing a low-friction interface, this bearing helps to ensure that these components operate efficiently and reliably, contributing to the overall performance of the truck.

Key Features

The Cummins 3915765 Needle Bearing is characterized by its robust design and high-quality materials. It features precision-ground rollers and races, which ensure smooth operation and minimal wear. The bearing is constructed from durable materials that can withstand the high loads and speeds typical of commercial truck applications. Additionally, it incorporates advanced lubrication systems to maintain performance over extended periods.

Benefits

The Cummins 3915765 Needle Bearing offers several benefits in truck operations. It provides improved efficiency by reducing friction between moving parts, which can lead to lower fuel consumption and enhanced performance. The bearing’s design also contributes to reduced wear and tear, resulting in enhanced durability and longer service life. Furthermore, its ability to handle high loads and speeds makes it a reliable choice for demanding truck applications 2.

Installation Considerations

Proper installation of the Cummins 3915765 Needle Bearing is crucial to ensure optimal performance and longevity. It is important to follow manufacturer guidelines for installation, including proper alignment and torque specifications. Common pitfalls to avoid include over-tightening, which can lead to premature failure, and inadequate lubrication, which can increase friction and wear.

Troubleshooting and Maintenance

Regular maintenance is key to ensuring the longevity of the Cummins 3915765 Needle Bearing. This includes periodic inspection for signs of wear or damage, such as noise, vibration, or abnormal heat. Troubleshooting common issues may involve checking for proper lubrication, alignment, and load distribution. Addressing these issues promptly can help prevent more serious problems down the line.

Performance in Various Conditions

The Cummins 3915765 Needle Bearing is designed to perform reliably under a range of operating conditions. It can handle varying temperatures, loads, and speeds, making it suitable for use in diverse truck applications. Its robust construction and advanced lubrication systems ensure that it maintains performance even in challenging environments.

Comparison with Other Bearing Types

When compared to other types of bearings, the Cummins 3915765 Needle Bearing offers distinct advantages in certain applications. Its compact design allows it to fit into spaces where larger bearings would not be feasible. Additionally, its ability to support high loads and speeds makes it a preferred choice for demanding truck applications. However, in applications where lower loads and speeds are encountered, other bearing types may be more appropriate.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company is committed to innovation and quality, continually developing new technologies to enhance the performance and reliability of its products.

Application in Cummins Engines

4B3.9 and B4.5 Engines

The Needle Bearing part number 3915765 is commonly used in the 4B3.9 and B4.5 engines. These engines are known for their reliability and efficiency, often used in a variety of applications including agricultural and industrial machinery. The needle bearing in these engines helps maintain the alignment and smooth rotation of the crankshaft, contributing to the overall performance and durability of the engine.

QSB3.9 and 30 CM550 Engines

In the QSB3.9 and 30 CM550 engines, the 3915765 Needle Bearing plays a similar role. These engines are typically found in heavy-duty applications, such as construction equipment and marine vessels. The needle bearing ensures that the connecting rods and other moving parts operate with minimal friction, which is crucial for maintaining the high torque and power output these engines are designed to deliver.

Importance of the Needle Bearing

The use of the 3915765 Needle Bearing across these engine models highlights its versatility and importance. By providing a stable and low-friction interface, this bearing helps to reduce wear and tear on engine components, leading to longer service intervals and lower maintenance costs. Its design allows it to withstand high loads and speeds, making it an essential part of the engine’s mechanical integrity.

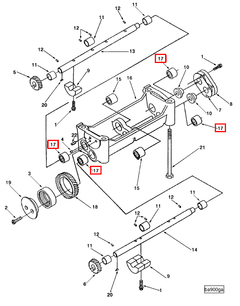

Role of Part 3915765 Needle Bearing in Engine Systems

In the context of engine systems, particularly with components like the balancer and engine balancer, the part 3915765 Needle Bearing serves an important function.

Integration with the Balancer

The balancer, a component designed to reduce vibrations by counteracting the forces generated by the engine’s moving parts, relies on smooth rotational motion. The 3915765 Needle Bearing facilitates this by providing a low-friction interface between rotating and stationary parts. This ensures that the balancer can operate efficiently, minimizing wear and enhancing the overall stability of the engine.

Contribution to the Engine Balancer

Similarly, the engine balancer, which is often a more complex version of the balancer, benefits from the precise fitting and smooth operation afforded by the 3915765 Needle Bearing. By allowing for seamless rotation, the bearing helps maintain the balancer’s effectiveness in counteracting engine vibrations, thus contributing to a more stable and reliable engine performance.

Overall Engine Performance

Incorporating the 3915765 Needle Bearing into these systems not only enhances their individual performances but also contributes to the engine’s overall efficiency. The reduced friction and smooth operation ensure that the engine can run more smoothly, with less wear on interconnected parts, ultimately leading to prolonged engine life and improved performance.

Conclusion

The Cummins 3915765 Needle Bearing is a critical component in the operation of commercial trucks and Cummins engines. Its design and features contribute to the efficiency, reliability, and longevity of the vehicles and engines in which it is used. Proper installation, maintenance, and understanding of its role in engine systems are essential for maximizing its benefits and ensuring optimal performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.