This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

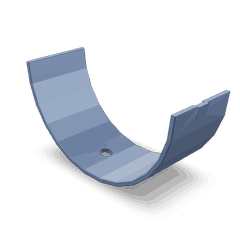

The Cummins 4007511 Connecting Rod Bearing is a critical component designed for use in heavy-duty truck engines. Its primary function is to facilitate smooth operation between the connecting rod and the crankshaft, ensuring efficient power transmission from the piston to the crankshaft. The significance of this bearing lies in its ability to reduce friction and wear, contributing to the engine’s overall performance and longevity 1.

Basic Concepts of Connecting Rod Bearings

Connecting rod bearings are essential components that enable the smooth rotation of the connecting rod around the crankshaft journal. They minimize friction between moving parts, which helps maintain engine efficiency and reduce wear. These bearings contribute to the engine’s performance and durability by ensuring that the reciprocating motion of the pistons is effectively converted into rotational motion of the crankshaft 2.

Role of the 4007511 Connecting Rod Bearing in Truck Operation

The 4007511 Connecting Rod Bearing operates within the engine by providing a low-friction interface between the connecting rod and the crankshaft. This bearing allows for the efficient transfer of power generated by the piston’s movement to the crankshaft, which then drives the truck’s wheels. Its interaction with other engine components, such as the crankshaft and connecting rod, is vital for the smooth and reliable operation of the engine 3.

Key Features of the 4007511 Connecting Rod Bearing

The 4007511 Connecting Rod Bearing is characterized by its material composition, which typically includes a steel backing and a bearing layer made from a combination of lead, tin, and copper. This design enhances its performance by providing excellent wear resistance and embeddability. The bearing’s unique characteristics, such as its precision engineering and high-quality materials, contribute to its effectiveness in heavy-duty applications 4.

Benefits of Using the 4007511 Connecting Rod Bearing

Utilizing the 4007511 Connecting Rod Bearing in an engine setup can lead to improved efficiency, durability, and reliability. Its design and material properties allow for reduced friction and wear, which in turn can lead to enhanced engine performance and longer component life. The bearing’s ability to withstand high loads and temperatures makes it suitable for the demanding conditions encountered in heavy-duty truck engines 5.

Installation and Maintenance

Proper installation of the 4007511 Connecting Rod Bearing involves ensuring a clean and undamaged bearing surface, using the correct tools for fitting, and following manufacturer guidelines to avoid damage. Maintenance practices include regular inspection for signs of wear or damage, proper lubrication, and adherence to recommended service intervals. These practices help ensure the longevity and optimal performance of the bearing 6.

Troubleshooting Common Issues

Common problems associated with connecting rod bearings include wear and failure, which can be caused by factors such as inadequate lubrication, misalignment, or excessive load. Troubleshooting steps may involve inspecting the bearing and journal surfaces for damage, checking lubrication systems for proper function, and ensuring correct installation and maintenance practices are followed to prevent recurrence 7.

Performance Enhancements

The 4007511 Connecting Rod Bearing contributes to engine performance enhancements by providing a smooth and reliable interface between the connecting rod and crankshaft. This results in more efficient power transmission, which can lead to smoother engine operation and potentially increased power output. The bearing’s design and material properties are tailored to meet the demands of heavy-duty applications, ensuring optimal performance under various operating conditions 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation in the automotive industry, particularly for its diesel engines and components, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and global presence underscore its position as a leader in the production of reliable and efficient power solutions 9.

Cummins Connecting Rod Bearing Part 4007511 Compatibility

The Cummins Connecting Rod Bearing part number 4007511 is designed to fit seamlessly within a range of Cummins engines, ensuring optimal performance and longevity. This part is engineered to meet the rigorous demands of heavy-duty applications, providing reliable support and reducing friction within the engine’s crankshaft and connecting rod assembly.

QSK78 Series

The QSK78 series engines, including the QSK78 CM500, are part of Cummins’ lineup of high-performance diesel engines. These engines are known for their robust construction and efficiency, making them suitable for various industrial and power generation applications. The part 4007511 is specifically designed to fit within the QSK78 series, ensuring that the engine operates smoothly and efficiently.

CM500 Series

The CM500 series engines are another example of Cummins’ commitment to delivering high-quality, reliable power solutions. These engines are engineered to provide exceptional performance and durability, making them ideal for demanding applications. The connecting rod bearing part 4007511 is a critical component in these engines, providing the necessary support and reducing wear on the crankshaft and connecting rod.

Grouping of Engines

The Cummins Connecting Rod Bearing part 4007511 is compatible with a variety of Cummins engines, including but not limited to the QSK78 and CM500 series. This part is designed to fit within the engine’s crankshaft and connecting rod assembly, ensuring that the engine operates smoothly and efficiently. By using this part, engine owners can expect improved performance, reduced wear, and increased longevity of their engines 10.

Role of Part 4007511 Connecting Rod Bearing in Engine Systems

The 4007511 Connecting Rod Bearing is an essential component in the efficient operation of various engine systems. It facilitates the smooth functioning of the engine piston by reducing friction between the connecting rod and the crankshaft. This bearing is integral to the engine top-level assembly piston system, ensuring that the reciprocating motion of the piston is effectively translated into rotational motion of the crankshaft.

In the context of the cylinder head and camshaft, the 4007511 bearing indirectly supports their operation by maintaining the overall balance and efficiency of the engine. A well-lubricated and properly functioning bearing allows for consistent engine performance, which is vital for the timing and operation of the camshaft and its interaction with the cylinder head.

The bearing also plays a supportive role in the fuel manifold and injector systems. Efficient engine operation, driven by smooth piston movement, ensures that fuel is injected at the optimal time and in the correct quantity. This, in turn, enhances combustion efficiency and overall engine performance.

Furthermore, the 4007511 bearing is important for the injector plumbing and the general head and cylinder assembly. It ensures that the mechanical stresses are evenly distributed, reducing wear and tear on other components. This bearing’s role in maintaining engine balance is key to the longevity and reliability of the entire engine system.

Conclusion

In summary, the 4007511 Connecting Rod Bearing is a fundamental part that supports multiple engine systems, from the piston and crankshaft to the camshaft and fuel injection components, ensuring smooth and efficient engine operation. Its design and material properties contribute to the overall performance, durability, and reliability of heavy-duty truck engines.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

Cummins Inc. (n.d.). QSK50 CM2350 K146G, Service Manual (5612932).

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009).

↩ -

Cummins Inc. (n.d.).

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021).

↩ -

Fehan, D. R. (2013).

↩ -

Cummins Inc. (n.d.).

↩ -

Cummins Inc. (n.d.).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.