This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4011611 Thrust Bearing is a specialized component designed for use in heavy-duty truck engines. Its purpose is to manage axial loads within the engine, ensuring smooth operation and contributing to the overall efficiency and longevity of the engine. Understanding the role and significance of this thrust bearing is vital for maintaining and optimizing the performance of heavy-duty engines.

Basic Concepts of Thrust Bearings

Thrust bearings are mechanical components that facilitate the management of axial loads—forces that act parallel to the axis of rotation. In mechanical systems, these bearings play a role in supporting and guiding rotating shafts, preventing excessive wear and ensuring stable operation. The principles of axial load management are fundamental to the efficient functioning of engines, as they help maintain alignment and reduce friction. Thrust bearings contribute to engine efficiency and longevity by effectively handling these axial forces 1.

Purpose of the 4011611 Thrust Bearing

The Cummins 4011611 Thrust Bearing is specifically designed to handle axial loads within a truck engine. It operates by supporting the crankshaft and other rotating components, allowing them to function smoothly under various load conditions. This bearing contributes to the overall performance and reliability of the engine by ensuring that axial forces are properly managed, thereby reducing wear and enhancing stability.

Key Features

The Cummins 4011611 Thrust Bearing boasts several primary features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to wear and capable of withstanding high loads. Unique characteristics such as precision engineering and robust construction ensure that the bearing can operate efficiently under demanding conditions. These features contribute to the bearing’s ability to provide reliable performance in heavy-duty applications 2.

Benefits

Using the Cummins 4011611 Thrust Bearing in heavy-duty truck engines offers several advantages. One of the key benefits is improved load distribution, which helps in reducing stress on other engine components. Enhanced engine stability is another advantage, as the bearing ensures that the crankshaft and other rotating parts remain aligned and operate smoothly. Additionally, the bearing’s durable construction contributes to increased service life, making it a cost-effective choice for engine maintenance 3.

Installation and Integration

Proper installation of the Cummins 4011611 Thrust Bearing is crucial for ensuring optimal performance. Guidelines for installation include correct alignment of the bearing within the engine assembly and adherence to specified torque values. Attention to these details during installation helps prevent issues such as misalignment and ensures that the bearing functions as intended, contributing to the engine’s overall efficiency 4.

Troubleshooting and Maintenance

Common issues associated with thrust bearings include wear, misalignment, and inadequate lubrication. Identifying these problems early can prevent more significant engine damage. Maintenance tips for prolonging the life of the Cummins 4011611 Thrust Bearing include regular inspection intervals to check for signs of wear or damage, and ensuring that proper lubrication practices are followed. These practices help maintain the bearing’s performance and extend its service life.

Performance Under Various Conditions

The Cummins 4011611 Thrust Bearing is designed to perform reliably under a range of operating conditions. Whether subjected to high loads, extreme temperatures, or varying speeds, this bearing maintains its efficiency and reliability. Its robust construction and high-quality materials enable it to withstand the rigors of heavy-duty truck engine operation, ensuring consistent performance in diverse environments.

Cummins Corporation

Cummins Inc. is a renowned manufacturer with a rich history in the automotive and heavy-duty truck industry. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts. Cummins is known for its commitment to quality and innovation, particularly in engine components. The Cummins 4011611 Thrust Bearing is a testament to the company’s dedication to providing reliable and high-performance parts for the automotive industry.

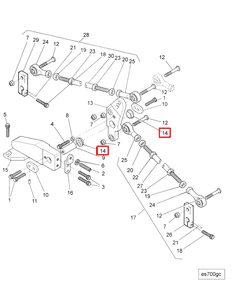

Role of Part 4011611 Thrust Bearing in Engine Systems

The 4011611 Thrust Bearing is integral to the smooth operation of various engine components by providing necessary support and reducing friction. Here’s how it interfaces with specific components:

-

Control Assembly Support: The thrust bearing ensures that the control assembly support operates with minimal friction, allowing for precise adjustments and reliable performance.

-

Control Linkage Lever: By fitting into the control linkage lever system, the thrust bearing facilitates smooth movement and reduces wear, enhancing the durability of the linkage mechanism.

-

Control Linkage Support: It supports the control linkage support, ensuring that the linkage can move freely without excessive friction, which is vital for the accurate transmission of control signals.

-

Governor Assembly Linkage: In the governor assembly linkage, the thrust bearing allows for smooth operation of the linkage, which is essential for maintaining consistent engine speed under varying loads.

-

Governor Assembly Shaft: The bearing fits around the governor assembly shaft, providing a low-friction surface that enables the shaft to rotate smoothly, which is necessary for the governor to function correctly.

-

Governor Control Linkage: It interfaces with the governor control linkage, ensuring that the linkage can move without undue resistance, which is important for the precise control of engine functions.

-

Governor Counter Assembly Linkage: The thrust bearing supports the governor counter assembly linkage, allowing it to operate efficiently and reducing the likelihood of mechanical failure.

-

Governor Linkage: Within the governor linkage system, the bearing ensures that all moving parts can operate with minimal friction, contributing to the overall reliability of the governor system.

-

Linkage: General linkage components benefit from the thrust bearing by experiencing reduced wear and tear, which prolongs the lifespan of the linkage system.

-

Governor Control: The bearing’s role in the governor control system is to provide a smooth operating environment, ensuring that control adjustments are transmitted accurately.

-

Linkage Assembly Support: It supports the linkage assembly, allowing for fluid movement and reducing the stress on other components within the assembly.

-

Throttle Assembly Shaft: When integrated with the throttle assembly shaft, the thrust bearing ensures that the shaft can rotate smoothly, which is essential for the precise control of fuel delivery.

-

Throttle Shaft: Finally, the thrust bearing fits around the throttle shaft, providing a low-friction interface that allows for smooth and accurate throttle adjustments.

Conclusion

The Cummins 4011611 Thrust Bearing is a critical component in heavy-duty truck engines, designed to manage axial loads and ensure smooth operation. Its robust construction, high-quality materials, and precise engineering make it a reliable choice for maintaining engine efficiency and longevity. Proper installation, regular maintenance, and understanding its role within the engine system are essential for maximizing the benefits of this thrust bearing.

-

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, Simon Baseley, SAE International, 2014.

↩ -

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, and Simon Baseley, SAE International, 2014.

↩ -

Gas Turbine Engineering Handbook 4th Edition, Meherwan P Boyce, Butterworth-Heinemann, 2011.

↩ -

Diesel Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.