This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4012889 Needle Bearing is a specialized component designed for use in commercial trucks. Manufactured by Cummins, a company renowned for its high-quality engine and powertrain solutions, this part is integral to the smooth operation of truck engines, contributing to their efficiency and reliability.

Basic Concepts of Needle Bearings

Needle bearings, a type of rolling-element bearing, utilize elongated rollers to support and reduce friction between moving parts. They are particularly effective in space-constrained applications requiring high load capacities. These bearings allow one surface to roll over another with minimal resistance, reducing wear and tear on mechanical components. They are commonly used in automotive engines to support shafts and other rotating elements 1.

Role of the 4012889 Needle Bearing in Truck Operation

In commercial trucks, the 4012889 Needle Bearing is positioned in areas needing to support rotating components under high loads, such as in the camshaft or crankshaft systems. By facilitating smooth rotation and reducing friction, this bearing contributes to the overall efficiency and longevity of the truck’s engine 2.

Key Features of the 4012889 Needle Bearing

Characterized by its robust design and high-quality materials, the 4012889 Needle Bearing is constructed using precision-engineered rollers and races, often made from hardened steel to withstand high loads and stresses. Its design includes features that enhance performance, such as optimized roller length and diameter ratios, providing a balance between load capacity and space efficiency. Additionally, the bearing may incorporate seals or shields to protect against contaminants, ensuring longevity and reliable operation 3.

Benefits of Using the 4012889 Needle Bearing

The use of the 4012889 Needle Bearing in commercial trucks offers several benefits. Its design allows for efficient operation under high loads, contributing to improved engine performance and fuel efficiency. The bearing’s durability ensures long service life, reducing the need for frequent replacements and maintenance. Furthermore, the reduced friction provided by the needle bearing helps in minimizing wear on adjacent components, leading to overall enhanced reliability of the truck’s engine.

Installation Considerations

Proper installation of the 4012889 Needle Bearing is crucial for ensuring its optimal performance and longevity. It is important to follow manufacturer guidelines regarding clearances, alignment, and torque specifications during installation. Careful handling is required to avoid damage to the bearing surfaces. Additionally, ensuring that the bearing is properly lubricated before and after installation can significantly impact its performance and lifespan.

Maintenance and Troubleshooting

Maintaining the 4012889 Needle Bearing involves regular inspection for signs of wear, contamination, or damage. Proper lubrication is key to its longevity, and it is important to use the recommended lubricants and follow the specified maintenance intervals. Troubleshooting common issues, such as unusual noise or vibration, may involve checking for proper alignment, adequate lubrication, and the absence of contaminants within the bearing. Addressing these issues promptly can prevent more significant problems down the line.

Performance in Various Conditions

The 4012889 Needle Bearing is designed to perform reliably under a range of operating conditions. It can handle varying loads and speeds, making it suitable for the demanding environments typical of commercial truck operations. The bearing’s performance is also influenced by environmental factors, such as temperature and exposure to contaminants. Its robust construction and protective features help it maintain functionality in these challenging conditions.

Cummins: Manufacturer Overview

Cummins is a leading manufacturer in the engine and powertrain industry, with a reputation for quality, innovation, and reliability. The company has a long history of developing advanced engine technologies and components, including bearings, that meet the rigorous demands of commercial and industrial applications. Cummins’ commitment to excellence is evident in their comprehensive approach to product design, manufacturing, and customer support, ensuring that their components, like the 4012889 Needle Bearing, deliver exceptional performance and durability.

Role of Part 4012889 Needle Bearing in Engine Systems

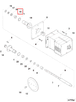

Actuator Shaft

The needle bearing, part 4012889, is instrumental in the smooth operation of the actuator shaft. By providing a low-friction interface, it ensures that the shaft can rotate with minimal resistance. This is essential for precise control of the actuator, which in turn affects the overall performance and responsiveness of the engine system.

Governor

In the governor mechanism, the needle bearing facilitates the smooth movement of rotating components. This is vital for maintaining consistent engine speed under varying loads. The bearing’s ability to handle radial loads while allowing for rotational movement ensures that the governor can accurately regulate engine performance.

Electronic Components

For electronic systems integrated within the engine, the needle bearing supports components that require rotational motion with high precision. Its low-friction properties help in reducing wear and tear on electronic parts, ensuring longevity and reliable performance of the engine’s electronic control systems.

Housing and Sleeve

Within the housing and sleeve assemblies, the needle bearing plays a key role in maintaining alignment and reducing friction between moving parts. This is particularly important in high-stress areas where components are subject to significant mechanical loads. The bearing ensures that these parts operate smoothly, contributing to the overall durability of the engine.

Protective Cover

The needle bearing is often housed within a protective cover to shield it from contaminants and external damage. This cover, combined with the bearing, ensures that the internal components remain clean and operate efficiently, prolonging the lifespan of the engine system.

Throttle Kit

In the throttle kit, the needle bearing allows for the smooth operation of the throttle mechanism. This is essential for precise control over the airflow into the engine, directly impacting the engine’s performance and fuel efficiency. The bearing’s role here is to ensure that the throttle can respond quickly and accurately to driver inputs.

Valve

The needle bearing is also utilized in valve mechanisms to facilitate smooth operation. By reducing friction, it allows the valve to open and close with greater precision, which is crucial for maintaining optimal engine performance and efficiency. The bearing’s durability under high-cycle applications ensures consistent valve operation over time.

Throttle

Finally, in the broader context of the throttle system, the needle bearing ensures that all moving parts within the throttle assembly operate with minimal friction. This is essential for maintaining the throttle’s responsiveness and accuracy, directly influencing the engine’s performance and drivability.

Conclusion

The Cummins 4012889 Needle Bearing is a critical component in the efficient and reliable operation of commercial truck engines. Its design, featuring precision-engineered rollers and races, ensures high performance under demanding conditions. Proper installation, maintenance, and understanding of its role within various engine systems are essential for maximizing its benefits and ensuring the longevity of the engine.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.