This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4100760 Bearing Spacer is a component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining the optimal performance of commercial trucks.

Basic Concepts of Bearing Spacers

Bearing spacers are components used in mechanical systems to maintain proper spacing between bearings. They ensure that bearings are correctly aligned and operate within specified clearances. This alignment is vital for the efficient operation of machinery, as it helps to reduce friction, wear, and the potential for mechanical failure. In the context of commercial trucks, bearing spacers play a role in supporting the smooth operation of various mechanical components 1.

Purpose of the 4100760 Bearing Spacer

The 4100760 Bearing Spacer is specifically designed to fit within the mechanical system of a truck. Its primary function is to maintain the correct distance between bearings, ensuring they operate efficiently. By doing so, it contributes to the stability and performance of the truck’s mechanical components, facilitating smooth operation and reducing the likelihood of mechanical issues.

Key Features

The 4100760 Bearing Spacer is characterized by its material composition and design. It is made from durable materials that can withstand the rigors of commercial truck operation. Its design is tailored to fit precisely within the truck’s mechanical system, ensuring optimal performance. Additionally, it may feature unique attributes that enhance its durability and effectiveness in maintaining bearing alignment.

Benefits of Using the 4100760 Bearing Spacer

Utilizing the 4100760 Bearing Spacer offers several advantages. Its durable construction contributes to improved longevity, while its precise design enhances the performance of the truck’s mechanical system. Over time, the use of this bearing spacer can lead to potential cost savings by reducing the need for frequent repairs or replacements of mechanical components.

Installation and Usage

Proper installation of the 4100760 Bearing Spacer is crucial for ensuring its effectiveness. This process involves preparatory steps to clean and inspect the installation area, followed by the careful placement of the spacer between bearings. Tools required for installation may include wrenches and alignment tools to ensure the spacer is correctly positioned. Adhering to best practices during installation helps to ensure optimal performance and longevity of the bearing spacer 2.

Troubleshooting Common Issues

Common problems associated with bearing spacers can include misalignment, wear, or damage. Addressing these issues involves diagnostic steps to identify the root cause of the problem. Solutions may range from realigning the spacer to replacing it if it is worn or damaged. Regular inspections can help to identify potential issues before they lead to more significant mechanical problems.

Maintenance Tips

Regular maintenance of the 4100760 Bearing Spacer is important for prolonging its lifespan and ensuring consistent performance. This includes routine inspections to check for signs of wear or damage, as well as cleaning the spacer and its surrounding components to remove dirt and debris. Following these maintenance tips can help to prevent issues and ensure the bearing spacer continues to operate effectively.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and commitment to excellence, Cummins continues to be a leader in providing solutions for the commercial truck market, including components like the 4100760 Bearing Spacer.

Role of Part 4100760 Bearing Spacer in Engine Systems

In the context of engine systems, the 4100760 Bearing Spacer is instrumental in maintaining the precise alignment and spacing between various rotating components. This ensures optimal performance and longevity of the engine.

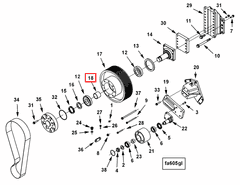

Drive System Integration

Within the drive system, the 4100760 Bearing Spacer is positioned between the drive components to maintain consistent spacing. This spacing is essential for the smooth operation of the drive mechanism, reducing friction and wear on adjacent parts. Proper alignment facilitated by the Bearing Spacer allows for efficient power transmission from the engine to the driven components, enhancing overall system reliability.

Fan Assembly Application

In the fan assembly, the 4100760 Bearing Spacer plays a significant role in supporting the fan blades and the fan hub. By ensuring that the fan components are correctly spaced, the Bearing Spacer helps in maintaining the balance and stability of the fan during operation. This is particularly important in high-speed applications where even minor misalignments can lead to increased vibration and potential failure of the fan system.

Fan Hub Support

The fan hub, which is the central part of the fan assembly, relies on the 4100760 Bearing Spacer to maintain its positional integrity relative to the shaft and other connected components. The Bearing Spacer ensures that the fan hub remains centered, which is vital for the uniform distribution of airflow. This consistent airflow is necessary for effective cooling of the engine and other critical components, thereby contributing to the engine’s thermal management system.

Conclusion

The 4100760 Bearing Spacer by Cummins is a vital component in the maintenance and operation of commercial truck engines. Its role in ensuring proper spacing and alignment between bearings contributes significantly to the efficiency, reliability, and longevity of the engine systems. Regular maintenance and proper installation are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.