The Cummins part 42647, a Main Bearing Cap, is a critical component in the engine assembly, ensuring the smooth operation of the crankshaft by providing a stable and secure interface between the crankshaft and the engine block. This part is designed to fit seamlessly within the engine architecture of various Cummins engines, including the N14 MECHANICAL and NH/NT 855 models.

Function and Operation

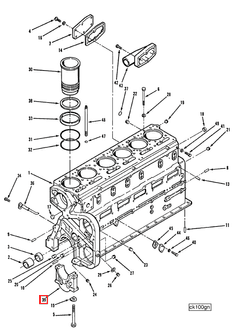

The Main Bearing Cap (part 42647) supports the crankshaft by securing the main bearings in place. This ensures that the crankshaft remains aligned and operates smoothly within the engine block. The cap interacts with the crankshaft, main bearings, and engine block, contributing to the overall stability and efficiency of the engine. Proper functioning of the main bearing cap is vital for the crankshaft’s rotational movement and the engine’s performance 1.

Design and Construction

This Cummins part is designed with precision to meet the demanding requirements of heavy-duty engines. It is constructed using high-strength materials that can withstand the rigors of heavy-duty use. The manufacturing process involves precision machining to ensure that the cap fits perfectly with the engine components. Unique design elements may include reinforced sections to enhance durability and performance under high stress conditions 2.

Key Features

Several key features contribute to the performance and durability of the 42647 Main Bearing Cap. Precision machining ensures a perfect fit with the engine components, while high-strength materials provide the necessary durability for heavy-duty applications. Additional design elements may include oil passages to ensure proper lubrication of the main bearings, enhancing the overall performance and longevity of the engine 3.

Benefits

The 42647 Main Bearing Cap offers several benefits that contribute to engine reliability and efficiency. Its precise design and high-strength materials enhance durability under heavy-duty conditions. Proper lubrication and alignment of the crankshaft contribute to overall engine efficiency, ensuring smooth operation and reduced wear on engine components.

Installation and Maintenance

Proper installation of the 42647 Main Bearing Cap is vital to ensure engine performance and longevity. It should be installed according to the manufacturer’s guidelines, with attention to torque specifications to ensure a secure fit. Regular maintenance, including inspections for wear and proper torque, is recommended to ensure optimal performance and longevity of the component.

Troubleshooting Common Issues

Common issues associated with main bearing caps include wear and tear, misalignment, and oil starvation. Regular inspections can help identify these issues early. Misalignment may require re-torquing or replacement, while oil starvation may indicate a lubrication system issue that needs addressing. Proper diagnosis and timely intervention can prevent more severe engine damage.

Cummins: Manufacturer Overview

Cummins Inc. is a reputable manufacturer in the automotive industry, known for producing high-quality engine components. With a history of innovation and commitment to quality, Cummins has established a strong reputation for reliability and performance in the heavy-duty truck market. Their components, including the 42647 Main Bearing Cap, are designed to meet the demanding requirements of heavy-duty applications.

Applications

The 42647 Main Bearing Cap is designed for use in heavy-duty trucks and engines that require robust and reliable components. It is compatible with a range of Cummins engines, providing the necessary support and stability for the crankshaft in demanding applications.

Role of Part 42647 Main Bearing Cap in Engine Systems

The part 42647 Main Bearing Cap is an integral component in the assembly and functionality of various engine systems. Its primary function is to secure the main bearings in place, which are essential for the smooth rotation of the crankshaft within the engine block.

When integrating with Base Parts and Block Cylinder, the Main Bearing Cap ensures that the main bearings are correctly aligned and held firmly. This alignment is vital for maintaining the precision of the crankshaft’s movement, which directly influences the engine’s performance and longevity.

In the context of a Block Short Kit or any Short Block configuration, the Main Bearing Cap plays a significant role. It is part of the assembly that includes the Block, Cyl Short NTC-300, Cyl Short NTC-350, and Cyl Short NTC-400. Each of these configurations relies on the Main Bearing Cap to maintain the integrity of the crankshaft journal, ensuring that the engine operates efficiently and reliably.

For engines utilizing the Block, Cylinder HR NH5-1/8, the Main Bearing Cap is equally important. It contributes to the stability of the crankshaft, which is particularly significant in high-performance or high-stress engine applications.

In a Cylinder (Service) Block or a Cylinder Block, the Main Bearing Cap’s role extends to facilitating easy maintenance and serviceability. It allows for the removal and replacement of main bearings without requiring extensive disassembly of the engine, thereby reducing downtime and repair costs.

Lastly, within a Cylinder Short Block or any Parts Base assembly, the Main Bearing Cap ensures that the crankshaft is supported adequately. This support is essential for the engine’s balance and for preventing excessive wear on the crankshaft and main bearings.

Overall, the part 42647 Main Bearing Cap is a fundamental component in ensuring the structural and functional integrity of the engine’s crankshaft and bearing system across various engine configurations.

Conclusion

The Cummins part 42647, a Main Bearing Cap, is essential for the efficient and reliable operation of heavy-duty engines. Its precise design, high-strength materials, and critical role in maintaining crankshaft alignment and stability make it a vital component in engine systems. Proper installation, maintenance, and timely troubleshooting are key to maximizing the benefits of this part and ensuring the longevity and performance of the engine.

-

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.